The cocoa powder processing machine production line is a fully automatic processing line that converts cocoa beans into cocoa powder products. The main processes include pod opening, bean separation, impurity removal, roasting, peeling, grinding, and packaging.

During processing, cocoa beans are gradually transformed into cocoa nibs, cocoa liquor, cocoa butter, cocoa cake, and finally fine and uniform cocoa powder.

The cocoa powder production line provided by Shuliy generally has a capacity of 100–500 kg/h. For larger capacities, such as 1000–2000 kg/h, we can also offer customized solutions.

Welcome to contact us for a tailored production plan.

Cocoa Powder Production Process

- Pod opening and bean extraction: Mature cocoa pods are cut open with a pod-breaking machine to take out the beans. Fresh cocoa beans contain pulp, so they must be fermented and dried in large fermentation boxes before further processing.

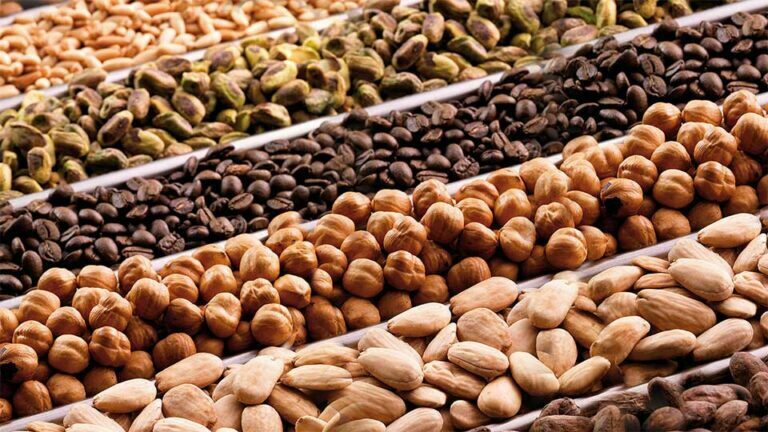

- Screening and cleaning: The dried cocoa beans are screened to remove stones, metals, fibers, and other impurities, ensuring raw material purity.

- Roasting: Cocoa beans are roasted under controlled temperature and time. This step removes excess moisture and enhances the unique cocoa aroma and flavor.

- Peeling and nib extraction: Roasted beans are fed into a peeling machine to remove the hard shell, producing cocoa nibs, the core raw material for cocoa products.

- Grinding into liquor: Cocoa nibs are ground into a fine cocoa liquor (also called cocoa mass). During grinding, cocoa butter is released, giving the mass a fluid texture.

- Pressing and separation: The liquor is pressed with a hydraulic press to separate it into cocoa butter and cocoa cake.

- Crushing and fine grinding: Cocoa cake is crushed and ground into powder. For higher fineness, ultrafine grinding equipment can be used.

- Sieving and packaging: The cocoa powder is sieved with a vibrating screen to ensure even fineness, then packed by an automatic packing machine into the final product.

Main Machines in Cocoa Powder Processing Line

Cocoa Pod Breaking Machine

- Capacity: 300–800 kg/h

- Power: 0.75 kW

- Voltage: 380 V, 50 Hz

- Dimensions: 1.6 × 0.6 × 1.9 m

- Material: Conveyor belt made of 201 stainless steel; frame and transmission parts made of carbon steel

- Weight: 150 kg

Function

The cocoa pod breaking machine is used to automatically cut open mature cocoa pods and efficiently extract whole cocoa beans. It provides high-quality raw material for subsequent fermentation, drying, and processing. This machine improves production efficiency, reduces labor costs, and ensures uniform and intact cocoa beans, making it a key first step in cocoa powder and chocolate production lines.

Cocoa Bean Screening Machine

- Model: TZC-400 / TZC-800 / TZC-2000

- Capacity: 300–2000 kg/h

- Power: 1.1 kW

- Voltage: 380 V, 50 Hz

- Dimensions (L×W×H): 2 × 1.3 × 1.7 m/ 4 × 1.5 × 2.3 m/ 4 × 1.5 × 2.3 m

Function

It uses a rotating drum structure to separate impurities such as stones, leaves, and twigs from cocoa beans. At the same time, it can grade the beans according to size, ensuring clean and uniform cocoa beans for subsequent roasting and processing. This high-efficiency, easy-to-operate equipment is an essential cleaning and grading machine in cocoa powder and chocolate production lines.

- Model: TZ-MHK series

- Transmission Power: 1.1–5.5 kW

- Heating Power: 22–75 kW

- Heating Gas Consumption: 2–15 kg per batch (approx.)

- Baked Yield: 80–650 kg/h (depending on model)

- Dimensions (L×W×H): approx. 3–5.5 m × 1.2–5.5 m × 1.7 m

Function

The cocoa bean roasting machine roasts cocoa beans under controlled temperature and time, removing excess moisture and developing the unique cocoa aroma and flavor. It provides a solid foundation for subsequent peeling and grinding.

Cocoa Bean Peeling Machine

- Power: 3kw

- Capacity: 300kg/h

- Weight: 500Kg

- Size: 2000*800*1650mm

Function

The cocoa bean peeling machine removes the shells of roasted cocoa beans to obtain whole cocoa nibs, ensuring clean raw material and providing a high-quality basis for cocoa liquor and cocoa powder production.

Cocoa Bean Grinder

- Capacity: 300 kg/h

- Power: 5.5 kW

- Material: Stainless steel

- Weight: 120 kg

- Dimensions: 100 × 50 × 120 cm

Function

Functions of Cocoa Bean Grinding Machine (Simple Version)

The cocoa bean grinding machine grinds roasted cocoa beans into fine cocoa liquor, evenly disperses cocoa solids and cocoa butter, ensures smooth texture, allows adjustable fineness, and is suitable for subsequent chocolate or cocoa product processing.

Cocoa Hydraulic Press Machine

- Power: 1.1kw

- Capacity: 300kg/h

- Weight: 1700Kg

- Size: 1300*900*1350mm

Function

The cocoa liquor press machine extracts cocoa butter from cocoa liquor through pressing, while producing cocoa cake. Cocoa butter can be used in chocolate production, and cocoa cake serves as raw material for cocoa powder.

Crushing Machine

- Power: 7.5kw

- Capacity: 300kg/h

- Weight: 420Kg

- Size: 1300*900*1350mm

Function

The cocoa nib crushing machine breaks cocoa nibs into small pieces, improving grinding efficiency and producing more uniform and fine cocoa liquor or cocoa powder.

Cocoa Powder Grinding Machine

- Power: 1.1kw

- Capacity: 300kg/h

- Weight: 340Kg

- Size: 700*600*1450mm

Function

The cocoa powder grinding machine crushes and finely grinds cocoa cake into smooth and uniform cocoa powder. The fineness can be adjusted to meet different food processing requirements.

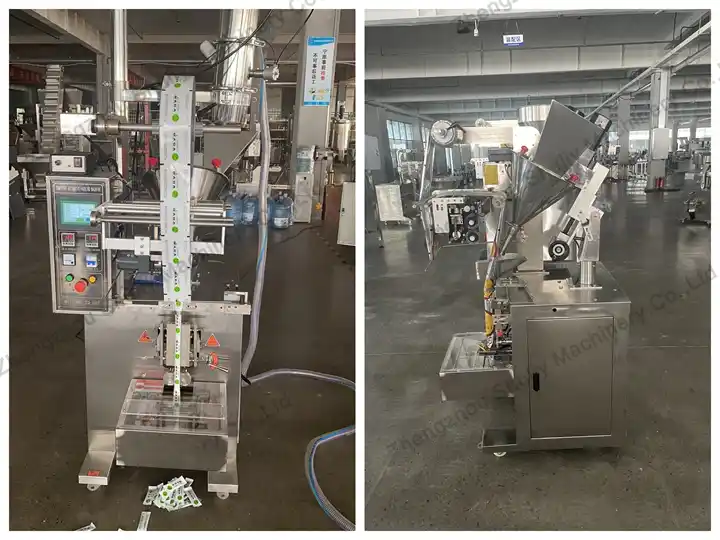

Cocoa Powder Packing Machine

- Packing Speed: 24–60 bags/min

- Bag Length: 30–150 mm

- Bag Width: 25–145 mm

- Filling Range: within 80 g

- Power Consumption: 2.2 kW

- Weight: 280 kg

- Dimensions (L×W×H): 0.65 × 1.05 × 1.75 m

Function

The cocoa powder packing machine automatically weighs and packs the ground cocoa powder, ensuring hygiene, neat packaging, and convenient transportation and sales.

Cocoa Powder Processing Machine Production Line – Advantages

High Automation & Efficiency

The entire production line is fully automatic, integrating cocoa bean roasting, peeling, grinding, pressing, powder milling, and packaging. Production capacity ranges from 100 kg/h to 2000 kg/h, depending on model configuration, which significantly reduces labor costs and increases output consistency.

Premium Material & Hygienic Design

All key contact parts are made of food-grade stainless steel (SS304/SS316), ensuring corrosion resistance, easy cleaning, and no contamination, meeting international food safety standards.

Customizable Control System

Equipped with a PLC control system, which can be customized with Siemens or other advanced controllers, allowing precise control of temperature, roasting time, grinding fineness, and packaging speed for stable, high-quality output.

Precise Processing & Quality Control

- Roasting temperature: 120–160 °C adjustable

- Grinding fineness: 60–200 mesh

- Pressing capacity: up to 500 kg/h per press

These parameters ensure consistent cocoa aroma, fine powder texture, and uniform color.

Versatile & Modular Design

Each section (roasting, peeling, grinding, pressing, packaging) can operate independently or as part of the integrated line, allowing easy expansion or upgrading based on production needs.

Energy-Saving & Environmentally Friendly

Efficient heating and mechanical systems reduce energy consumption by up to 20–30% compared with traditional processes, while dust collection and sealing design minimize environmental pollution.

Stable & Reliable Operation

Heavy-duty motors and precision bearings ensure long service life, low maintenance, and continuous 24/7 operation capability.

Applications of Cocoa Powder Production Line

- Chocolate Production

- Baked Goods

- Beverage Processing

- Confectionery & Snacks

- Flavoring & Food Ingredients

- Cosmetics & Health Products

The cocoa powder production line is ideal for chocolate factories, beverage manufacturers, bakeries, and food processing enterprises, providing stable, high-quality cocoa powder to meet the needs of multiple industries.