The hydraulic oil press machine is a kind of machine that presses the hot Fried material to extract oil. It has the advantages of high oil yield, no pollution to oil, and so on, and it is suitable for nut products, peanut sesame, and other production lines. In general, the oil press is used in conjunction with the baking machine.

Characteristics of hydraulic oil press machine

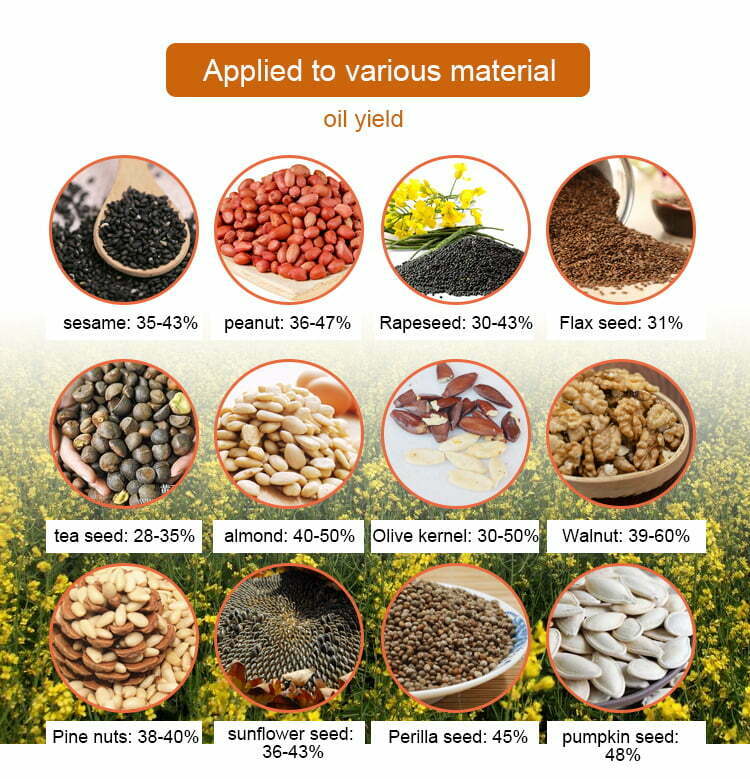

Wide range of applications

Firstly, hot pressing and cold pressing can be realized. The raw materials of hot-pressed oil include sesame, peanut, corn germ, etc., while the raw materials of cold-pressed health oil include cocoa beans, walnuts, almonds, macadamia nuts, olives, etc.

The quality of the oil is good after being pressed

Hydraulic oil press adopts pure physical press, high oil yield, low hybrid quality, and in the cold pressing process will not produce temperature, so it will not destroy the organic components of the material itself.

Simple structure, also easy to operate

The oil press adopts automatic pressing, so the operation steps are very simple, one operator can operate 3-4 sets, greatly saving the workforce. There are detailed operation methods of hydraulic oil press on our website

High press efficiency

From filling to cake basically can be completed within 8 minutes, the production efficiency is very high, to ensure the basic production and processing needs.

What is the difference between cold press and hot press oil?

Hot pressing

In some areas, it is also called cooked pressing. Simply put, the raw materials that need to be pressed are first subjected to high-temperature heat treatment, so that a series of changes in the oil will occur, destroying oil cells, promoting protein deformation, and reducing oil viscosity. It is used to improve oil production. common hand. The hot-pressed peanut oil has a pure taste and rich fuel tank, especially the oil-rich peanut oil is more suitable for hot pressing. However, the oil extracted by this process is darker in color and has an increased acid value. And some nutrients in the oil will be lost in the high temperature produced by hot pressing. such as vitamin E, sterols, and carotenoids.

Cold pressing

The cold pressing method, also known as the raw pressing method, refers to an oil pressing process in which the oil is sent to the oil press for pressing at a low temperature without heating or slightly heating before pressing. Cold pressing is generally processed in an environment below 60°C. In order to improve the quality of cold-pressed oil, the raw materials of oil-pressing generally need to be selected. The oil extracted by the cold pressing method has low oil temperature, low acid value, and high quality. Cold-pressed refined oil retains the natural flavor and color of the oil, completely preserves the nutrients in the oil, and has a low degree of protein denaturation, making it easier to comprehensively utilize protein. In general, cold-pressed oils have a lower smoke point and clearer color, and the color and luster sell better than hot-pressed oils. However, because the cold-pressed oil has not been steamed and fried, the water content in the oil is unstable, which is not conducive to long-term storage. Secondly, the aroma of the oil is not as strong as that of the hot-pressed oil. If the hot-pressed oil is a “strong-flavor type”, then the cold-pressed oil is a “fresh fragrance type”.

Although cold-pressed oil is original and is a healthy choice for life, the characteristics of oil plants are different. For example, cold-pressed soybean oil has a beany smell, which is not acceptable to everyone. For another example, cold-pressed sesame oil has a lighter fragrance, which loses the meaning of sesame oil. Therefore, when choosing the required process, it is necessary to comprehensively consider the characteristics of the material and the living habits of local consumers.

Why use a hydraulic oil press for pressing sesame?

In fact, among these two types of oil pressing equipment, most people prefer hydraulic oil presses for pressing sesame seeds. The reason is very simple. Sesame seeds are products with high oil yields. The oil rate is less than or equal to 5%. The hydraulic oil press has a high oil yield and is easy to operate. The oil yield of the sesame pressed by the screw oil press is 30%-35%, while the oil yield of the hydraulic oil press is 45%-47%. When pressing oil to prepare the oil, the uneven extrusion process will lead to a low oil yield. So that’s why pressing sesame chooses hydraulic oil press.

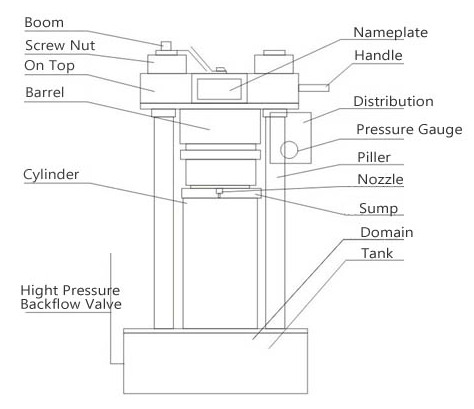

The structure of the hydraulic oil press machine

The main parts of the hydraulic oil press are piston, hydraulic cylinder, column, movable upper beam, base, oil pump, barrel, electric heating ring, and automatic temperature control device. The materials are all made of high-quality metal materials, which improves the performance of the machine and guarantees the service life of the components. The automatic hydraulic oil press uses the oil pressure from the pump station to generate pressure between the piston and the top so that the raw materials between the piston and the top can squeeze out the required oil under strong pressure. The hydraulic oil press adopts a vertical structure, which occupies a small area and has high working efficiency, which is loved by oil pressing companies.

Machine maintenance of sesame oil expeller machine

- This oil expeller machine is 220V voltage, including heating and control system using 220V power supply, of course, can also be changed to 380V according to customer demand.

- The hydraulic system of the machine belongs to the high-pressure class, so, overpressure should be avoided to avoid damage to the machine.

- During the operation of the oil press, the correct operation procedure must be followed strictly.

- After the oil is squeezed dry, should be immediately out of the cake, otherwise too long a time will appear a gas explosion phenomenon.

- But if a clog is found after use, a thin blade or needle can be used to clean up the tank.

Parameters of oil expeller machine

| Model | TZ-180 | TZ-230 | TZ-260 | TZ-320 |

| Size(mm) | 920*480*1190 | 1065*540*1550 | 900*1000*1560 | 980*1050*1680 |

| Weight(kg) | 450 | 880 | 1250 | 1680 |

| Pressure(kn) | 1600 | 2200 | 2600 | 3000 |

| Maximum use of working pressure | 55Mpa | 55Mpa | 55Mpa | 55Mpa |

| Electric heating power(KW) | 1 | 1 | 1.2 | 2 |

| Control the temperature of the heating ring(℃) | 70-100 | 70-100 | 70-100 | 70-100 |

| Motor type power(KW) | 3 (220v) | 1.5 | 1.5 | 2.2 |

We have various models of hydraulic oil presses, the smallest is TZ-180 and the largest is TZ-320. The above table is the detailed parameters of the oil press.

Oil cakes can also create economic value

Soybeans, sesame, peanuts, and other raw materials will leave oil cakes after pressing. Generally, these oil cakes can also be used to create benefits after oil pressing. The oil cakes can be used as fertilizers. In factories, the quantity is large and can be sold. In addition, the oil cake from oil extraction can also be used as feed. After pressing, the oil cake still contains a small amount of oil and other nutrients. It is a very good animal feed.

Types of oil presses machine

At present, there are two kinds of oil presses on the market, screw oil presses and hydraulic oil presses. Many people may not know how to choose when choosing. In fact, these two oil presses have their own advantages, and which oil press to choose It mainly depends on the raw material being pressed.

If you mainly press crops with high oil content such as sesame, almond, and walnut kernel, it is recommended to choose a hydraulic oil press, which is more convenient and quick to operate. If you want to press peanuts, rapeseeds, soybeans, sunflowers, tea seeds, and other oil crops, it is recommended to choose a multi-functional screw oil press equipment, which can process a wider range and a large processing volume, which can meet the requirements of processing operations with supplied materials and small and medium-sized Oil factory work.