The peanut roaster is an industrial device designed for large-scale peanut roasting, utilizing a rotating drum heating method combined with hot air circulation and mechanical tumbling to ensure even heating and roasting of peanuts.

This equipment is not only suitable for roasting peanuts but also ideal for processing other nuts and seeds such as soybeans, melon seeds, sesame, almonds, chickpeas, and more.

The drum inside the rotary peanut roaster is made of food-grade stainless steel, while the outer shell is constructed from carbon steel, offering durability, corrosion resistance, and ease of cleaning.

Heating options include electric heating, fuel oil, gas, and coal-fired models. The product comes in 5 different models, with single batch capacities ranging from 80 kg to 650 kg.

Additionally, we provide a complete range of peanut processing machinery, such as peanut peeling machines and peanut grinding machines.

Advantages of Peanut Roasters

High Efficiency and Energy Saving

Utilizes a rotary drum with heat conduction and radiation principles, combined with a thickened insulation layer to minimize heat loss and reduce energy consumption.

Uniform Roasting

The rotating drum with stirring design ensures even roasting of peanuts, resulting in better taste and texture.

High Automation

Equipped with a PLC intelligent control system, allowing adjustable upper and lower temperature limits for precise control of temperature and time.

Easy Operation

Features fixed feeding and discharging ports for convenient material handling.

Environmentally Friendly and Safe

Comes with a dust removal system to reduce dust pollution and comply with environmental regulations.

Low Noise

Smooth and uniform drum rotation with good sealing ensures quiet operation.

Premium Stainless Steel Materials

The drum is made of food-grade stainless steel for safety and hygiene, while the outer shell uses a durable, corrosion-resistant carbon steel structure.

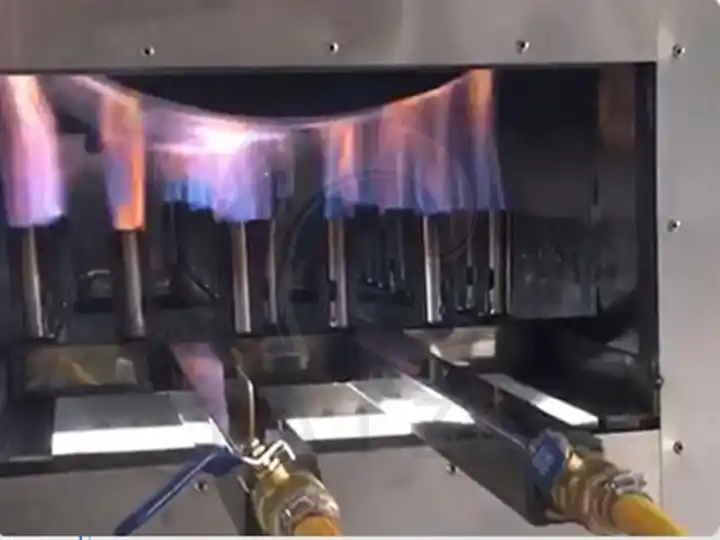

All Stainless Steel Burner Plate

Ensures more complete combustion, higher heat output, greater durability, and resistance to damage.

Wide Application and Simple Operation

Suitable for roasting peanuts, sesame, almonds, soybeans, melon seeds, and other crops — a versatile machine for multiple uses.

Wide Range of Options

Multiple models are available, and customisation is supported to meet specific requirements.

Main Structure of Factory Drum Peanut Roasting Machine

- Drum body: Made of high-temperature resistant stainless steel or carbon steel, equipped internally with spiral blades or scrapers to turn the peanuts, ensuring even roasting.

- Heating system: Uses a gas furnace, electric heating, or steam heating combined with hot air circulation for fast and uniform heat transfer.

- Drive system: Motor with a reducer drives the drum at low speed, ensuring peanuts are fully turned over.

- Control system: PLC intelligent control monitors temperature, rotation speed, and time, with multiple roasting programs available.

- Exhaust and dust removal system: Includes exhaust ducts and dust collectors to maintain a clean environment and prevent dust buildup.

How do Peanut Roasters Work?

- Peanuts are evenly fed into the drum through the feeding inlet, and the drum begins to rotate slowly.

- Heating tubes installed inside the drum generate heat, which roasts the peanuts through infrared radiation and hot air convection.

- The rotation of the drum and the stirring action of internal blades ensure even heating of the peanuts, preventing localized burning.

- After roasting is complete, the peanuts are discharged through the outlet and sent to cooling or the next processing stage.

Peanut Roasting Machine Parameters

Taizy Machine manufactures five models of peanut drying machines. Each machine can be heated by either electricity or gas, maintaining a consistent daily temperature of around 300°C.

| Model | TZ-MHK-1 | TZ-MHK-2 | TZ-MHK-3 | TZ-MHK-4 | TZ-MHK-5 |

| Transmission Power | 1.1KW | 2.2KW | 3.3KW | 4.4KW | 5.5KW |

| Heating Power | 22KW | 35KW | 45KW | 60KW | 75KW |

| Heating Gas (Kg) | 2-3 | 3-6 | 6-9 | 9-12 | 12-15 |

| Baked Yield | 80-120KG/H | 180-250KG/H | 280-350KG/H | 380-450KG/H | 500-650KG/H |

| Size (mm) | 3000*1200*1700 | 3000*2200*1700 | 3000*3300*1700 | 3000*4400*1700 | 3000*5500*1700 |

In addition to this, Taizy Machinery is able to support the customization of various models according to the needs of customers. Taizy Machinery also has follow-on processing machines, such as a peanut cake machine and a peanut butter grinder. If you are in need, welcome to visit our factory and shop for products.

Shipping Packaging Description

To ensure the equipment remains intact during transportation, we use sturdy and durable packaging materials. The exterior of the equipment is typically wrapped with waterproof and moisture-proof plastic film to prevent damage from rain and humidity. Inside, shock-absorbing foam or wooden braces are used to stabilize the equipment and protect it from impacts and vibrations during transit.

Packaging boxes are usually made of reinforced wooden crates or pallets, customized according to the size and weight of the equipment to facilitate loading, unloading, and stacking. Additionally, all packaging complies with international shipping standards to guarantee the safe and smooth delivery of the equipment.

Before shipment, we conduct strict inspections of the packaging to ensure it is complete and secure, and all packages are labeled with relevant shipping marks and protective warnings.