The almond shelling machine is a professional device for shelling apricot kernels. It can remove whole almonds from the shells with a shelling rate over 98%.

It is not only used for almonds, but also for various nuts, such as hazelnuts, palm kernels, macadamia, and more.

An efficient almond shelling machine is an essential part of the almond processing line, often used in the pre-treatment stage.

Taizy offers a small almond shelling machine with a capacity of 400 kg/h, this is a single almond cracking machine. We also provide complete almond shelling lines with a capacity of 2–3 tons per hour. Feel free to contact us for more details.

Advantages of the almond shelling machine

- High shelling rate and low breakage: unique single-pole design effectively removes almond shells while minimizing kernel damage, shelling rate over 98%, breakage rate below 3%

- Easy operation: compact structure, saves floor space, simple to operate, easy to maintain, and clean

- Energy saving and efficient: 2.2 kW motor with optimized transmission, smooth operation, and low energy consumption

- Adjustable shelling force: the shelling gap can be adjusted according to almond size and hardness, suitable for different raw materials

- Safe and reliable: sturdy body with safety protection devices, ensuring operator safety

- Wide application: besides almonds, also suitable for shelling hazelnuts, walnuts, and other nuts

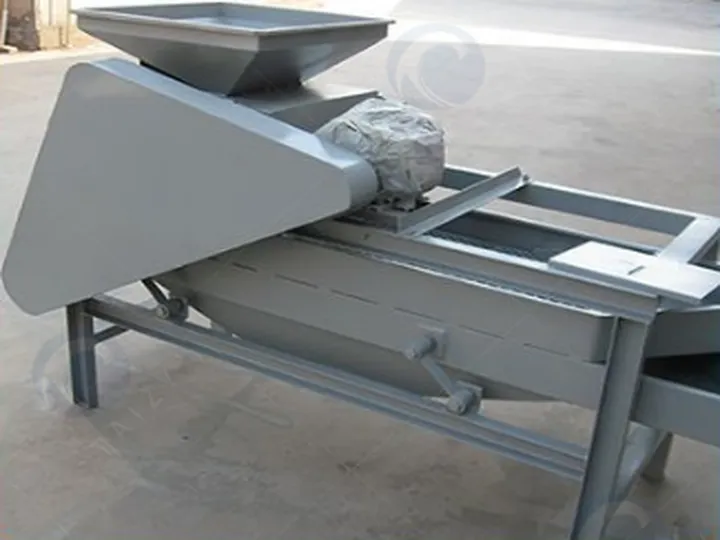

The structure of the apricot kernel shelling machine

Single-pole shelling mechanism

- Function: core shelling device, removes almond shells through rotation and compression

- feature: single-pole design, high shelling rate

Feeding hopper & conveyor

- function: delivers raw material evenly to the shelling mechanism for continuous processing

- feature: can use vibrating or screw feeding, prevents clogging

Motor & transmission

- function: provides power to drive the shelling mechanism

- feature: 2.2 kW motor, smooth operation, low energy consumption

Discharge outlet

- function: separates shelled kernels from shells for easy collection and packaging

- feature: optional air or sieve separation, improves efficiency

Adjustment mechanism

- function: adjusts the shelling gap and force to suit almonds of different sizes and hardness

- feature: simple operation, high flexibility

Safety guard

- function: prevents operators from touching moving parts, ensures safety

- feature: removable for cleaning, meets safety standards

How does the almond sheller work?

The almond shelling machine works by feeding almonds into the machine for shelling. Some almonds, especially smaller or harder ones, may not be fully shelled on the first pass and need to be separated with a sieve, then re-shelled by adjusting the shelling gap. The three-stage almond shelling machine offered by Dongxin Food Machinery can classify almonds into three sizes and complete shelling in a single pass, greatly improving efficiency and ensuring a high rate of intact kernels.

Description of machine parameters

| Model | Voltage | Power | Weight | Capacity | Size |

| TZ-AS400 | 220V | 2.2kw | 280kg | 400kg/h | 190cm*78*cm120cm |

If you have more customization requirements, we support custom solutions. You are welcome to contact us.

Correct feeding and operating steps of almond shelling machine

Preparation

Before operating the machine, check that the frame, shelling mechanism, and motor are secure and clean, and ensure there are no blockages. Adjust the shelling gap according to the size and hardness of the almonds, and confirm that the power supply and transmission system are working properly to ensure high efficiency and intact kernels.

Feeding operation

Pour almonds evenly into the feeding hopper, avoiding overloading, which can cause blockages or idle running. For small machines, feed slowly by hand; for larger production lines, use a vibration or screw conveyor to achieve continuous, stable processing.

Shelling process

Once the machine starts, almonds are crushed and impacted by the drum or single-pole shelling mechanism, separating the shells from the kernels. Monitor the discharge to ensure smooth separation while minimizing kernel breakage.

Screening and re-shelling

Some harder or smaller almonds may not be fully shelled on the first pass. Use a sieve or grading device to separate them, then adjust the shelling gap for a second pass. A three-stage shelling machine can classify and shell almonds in a single pass, greatly improving efficiency and reducing repeated operations.

Collection and cleaning

After shelling, collect the kernels and shells separately to facilitate further processing or packaging. Regularly clean the machine’s interior to remove residues, keeping the equipment clean and ensuring smooth operation, which extends its service life.

Safety and maintenance

Never place hands near moving parts during operation to avoid injury. Avoid overloading to prevent reduced shelling efficiency or machine damage. Regularly inspect the motor and transmission system to ensure stable and efficient operation.

Almond shelling production line

Taizy’s almond shelling production line has a capacity of 1–3 tons per hour and is designed for high-output continuous operation. It is an ideal solution for large-scale shelling plants, helping improve production efficiency and reduce operating costs, with key advantages including clean shelling, high kernel integrity, and easy cleaning and maintenance.

Production process flow

- Grading and feeding: Raw almond nuts are lifted to a rotary grading screen and separated into three or more sizes. After electromagnetic dosing from the hopper, the nuts are fed into three shelling machines.

- Shelling: The shelling gap can be adjusted according to nut size to ensure good shelling results and high kernel integrity, avoiding kernel damage.

- Shell–kernel separation: The shelled mixture is conveyed to a shell–kernel separator, which efficiently separates shells and kernels through two discharge outlets.

Main equipment configuration

| Equipment Name | Quantity |

|---|---|

| Elevator | 2 units |

| Rotary Grading Screen | 1 unit |

| Electromagnetic Dosing Hopper | 3 units |

| Shelling Machine | 3 units |

| Supporting Base (Height-Adjustable) | Several |

| Conveyor and Sorting Belt | 2 units |

| Dual VFD Shell–Kernel Separator | 2 units |

| Type 30 Gravity Destoner | 1 unit |

FAQ

Can I have a trial run?

Of course, after the shelling machine is ready, we will shoot the video of the trial run for you as soon as possible. After making sure there are no problems in all aspects, we will proceed with the next operation.

Are there any breakable parts?

After our tests and a lot of customer feedback, this almond/hazelnut shelling&cracking machine has no fragile parts.

If you have any problem in the later use process, please timely communicate with us, we will try our best to solve the problem for you.

How to adjust the roller that controls almond size?

We have a detailed manual for the use of the almond/hazelnut cracking machine, and just follow the steps in the manual, you can make accurate adjustments.

How much space does the equipment need?

A small machine occupies about 2 m² and can be placed flexibly. A complete production line generally requires 20–40 m² depending on capacity and can be customized according to the factory layout.

Is the machine power-consuming?

The small machine has a power of only 2.2 kW, runs smoothly, and consumes little energy. Large production lines use energy-efficient motors and optimized drives, and the energy consumption per unit is below the industry average.

Does the almond shelling machine require manual operation?

Small machines can be fed manually and are easy to operate. Large production lines generally use automatic feeding and grading systems for fully automatic continuous operation. Operators only need to monitor and maintain the system.

Is the almond shelling machine noisy during operation?

Generally, a small almond shelling machine operates at about 70–80 dB, similar to a vacuum cleaner. Large production lines may be slightly louder, but noise can be reduced by installing soundproof covers or vibration-damping pads.

Is the machine safe to operate?

The equipment is equipped with protective covers, anti-hand-in devices, and emergency stop buttons. Operators should follow instructions and avoid contact with moving parts to effectively reduce safety risks.

What about after-sales and customization services?

Taizy supports customized capacity and configurations and provides installation guidance, operation training, and after-sales maintenance. Motors, drives, and key components can be quickly replaced to ensure uninterrupted production.