Peanut is one of the important oil-bearing crops and also one of the common agricultural products. Peanut is also widely used in the food industry. After processing with different technologies, it can be made into a variety of peanut products. However, no matter what processing steps the peanut goes through, the only necessary step is to remove the shell. Which is the first step in all peanut food processing.

Open the peanut shells

When the peanut is harvested, because it grows in the soil, there is a certain amount of moisture on the whole. Therefore, it is necessary to remove the water contained in the peanut shell first. So as to remove the peanut shell more conveniently.

Generally, there are two ways to remove water. The first way is to air the peanuts. After a few days of drying, the water in the peanuts has almost completely evaporated.

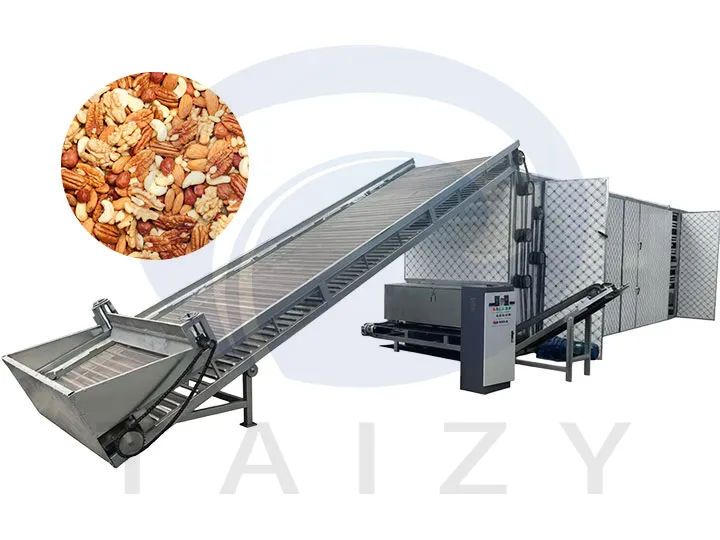

Another method is directly put peanuts in the dryer for drying. And the choice of the dryer is varied, including hot air circulation drying oven, mesh belt dryer, etc. With a machine drying, the biggest advantage is the drying cycle is short, can greatly improve the efficiency of peanut processing, at the same time, compared with natural drying cleaner. After the peanuts have been dried, they can be shelled.

In addition to the daily manual opening of shells, so far the most ideal way to open peanut shells is the peanut sheller. Which designed by professional mechanical experts according to the structural characteristics of peanuts. And now widely used in the production of a variety of peanut food manufacturers.

Introduction of peanut sheller

A peanut sheller is a machine that takes off the shell of peanut and keeps the peanut intact by rotating it at high speed.

Peanut sheller is a popular product developed according to the demand of the current peanut market. Its main characteristics are low crushing rate, clean sorting, good color, and fewer impurities, and the indicators meet the national standards.

Constituent structure

Peanut sheller has a frame, fan, rotor, screen, hopper, vibrating screen, triangle belt wheel, and its transmission triangle belt composition.

Operating principle

After the normal operation of the machine and tools. Then put the peanuts into the hopper quantitatively, uniformly, and continuously. Under the repeated impact, friction, and collision of the rotor, the peanut shell will be broken.

The peanut grains and the broken peanut shells pass through a sieve with a certain aperture under the rotating wind pressure and strike of the rotor. At this time, the peanut shells and grains are blown out of the body by the blowing force of the rotating fan. And the peanut grains screened out by the vibrating screen to achieve the purpose of cleaning.

A machine for open peanut shells is a must for food manufacturers

Since peanut food manufacturers have a large daily production, if the raw material is peanuts or groundnuts with shells, it is necessary to have a peanut shelling machine that meets the actual production requirements.

The selection of a high-quality machine can not only ensure the quality of peanuts in the pretreatment stage but also ensure that the later peanut processing process more smoothly, is the most ideal equipment manufacturers.