Peanut shelling machine in the peanut processing field is widely used. And according to different processing capacity, also divided into different specifications. The main function is to separate the peanut shell from the peanut kernel. But do you know how this process works?

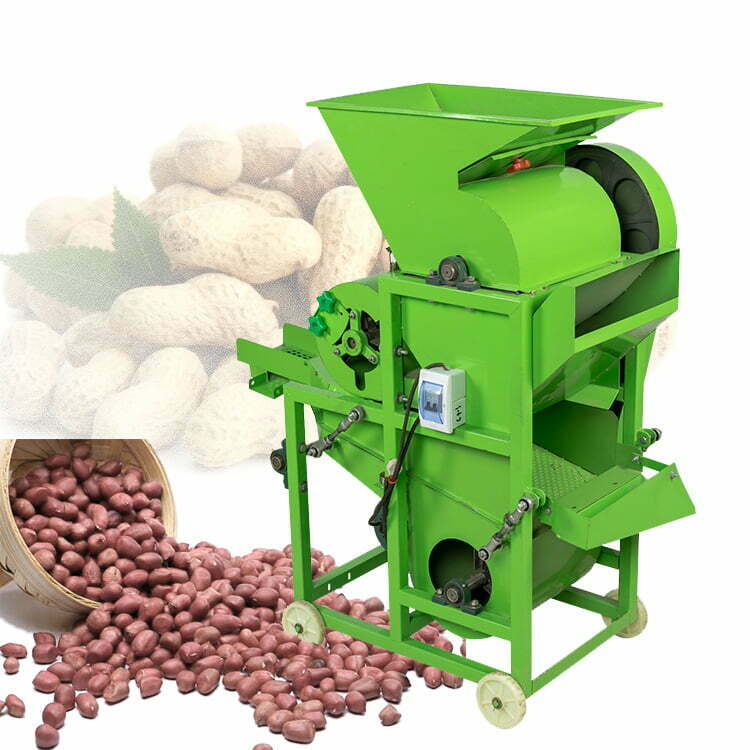

The composition of peanut sheller

First of all, let’s understand the structure of the machine.

The sheller mainly consists of a frame, a rotor, a motor, a fan, a screen, a vibrating screen, a triangular belt wheel in a hopper and so on.

The overall structure is not complex, so the operation is also extremely simple.

Operation steps

- Open the sheller, wait until the machine is in normal operation, manually put the peanuts into the hopper in a continuous and uniform quantity.

- The internal rotor of the machine repeatedly friction, strike and collision on the peanut, resulting in the peanut shell broken.

- The broken peanut shells and peanut grains pass through a fixed aperture screen under the action of rotating wind pressure of the rotor.

- During this process, the wind from the fan blows the lighter shells out of the machine. While the peanuts go into a vibrating screen, which is used to screen them for cleaning.

Preparation before peanut shelling machine operation

First of all, before use the peanut sheller, give the operator proper safety education and detailed description of the machine. So that the operator can be familiar with the structure, performance and operation method of the machine. Of course, the operator should equip with suitable working clothes.

Before starting the sheller. The operator should carry out an all-round inspection on the machine to ensure that there is no hidden safety problem.

Before feeding the peanuts into the hopper, the machine should to run for a few minutes, after which the machine should be ready for normal operation.