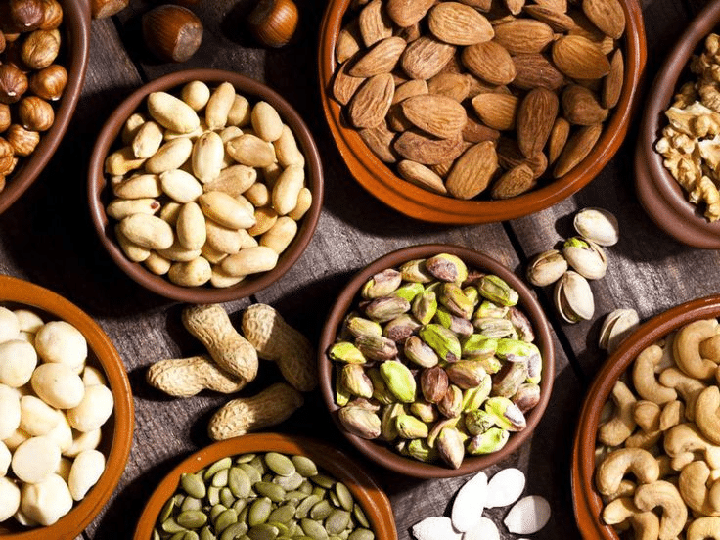

Mesh belt dryer is relatively common drying equipment, but also a continuous, large-scale energy-saving drying equipment. Not only nuts can be dried. But also a variety of crops, vegetables, fruits, Chinese herbs, food, etc. Heating methods can also be divided into electric heating, steam heating, and hot air heating according to different needs, which is conducive to energy conservation and emission reduction.

Why do nuts need to be roasted?

Through roasting, the fishy smell of nuts can be removed, their unique fruit aroma can be better released, the aroma will be stronger, and the taste of nuts after roasting will be crisper. Some common nuts, such as walnuts, cashews, almonds, pine nuts, hazelnuts, black sesame seeds, etc., can be roasted before use.

Application of mesh belt dryer for cashew

Nuts are usually dried after they have been peeled. And the mesh belt dryer is one option. Not only that, but mesh belt dryers are also widely used in food, chemistry, electronics, and other industrial fields.

The specific drying materials are the Food industry: nuts, dehydrated vegetables, dried fruits, scented tea, Chinese medicine, radish, pumpkin, grain feed, and so on. Chemical industry: rubber, medical materials, organic pigments, etc.

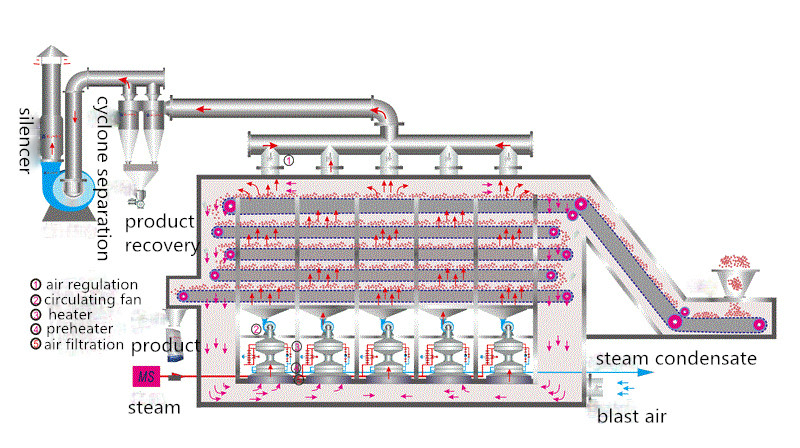

The working principle of mesh belt dryer

The raw material is evenly spread on the mesh belt. The driving device in the dryer drives the belt to move, then the uniform hot air passes through all the materials. And the steam produced is discharged from the special vent hole. So as to achieve the drying effect.

Among them, the moving speed of the mesh belt can be adjusted according to the actual type of material and humidity.

Moreover, the airflow in the dryer adopts porous air intake to ensure the uniform distribution of airflow and wind speed, which greatly improves the drying effect.

Mesh belt dryer for peanut features

- The dryer uses air circulation, highly energy-efficient. And the working process is not complicated

- Unique fan device, uniform distribution of hot air, ensure uniform drying of materials.

- The running speed of the mesh belt and the drying degree of the material can be flexibly adjusted.

- The drying efficiency is high and the moisture content of the dried material is generally lower than 5%.

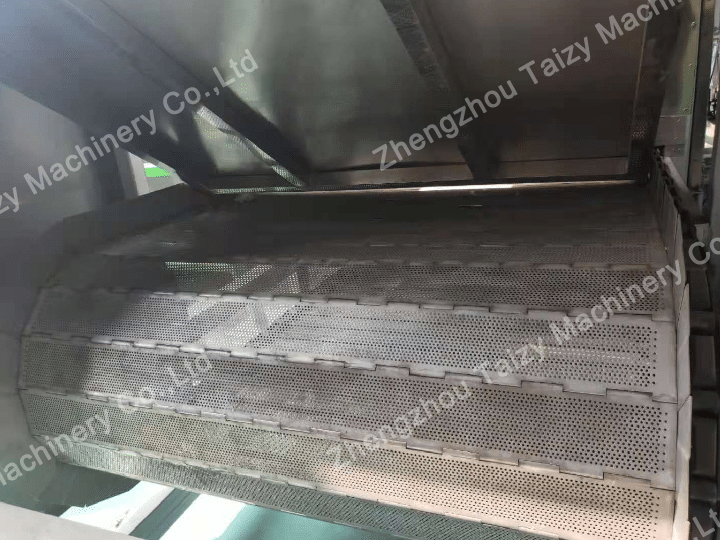

- The mesh belt uses high-quality stainless steel with high-temperature resistance.

- The equipment configuration is flexible, the user can choose the equipment configuration flexibly according to the actual production volume and material type.

- Wide range of use, so not limited to one kind of material drying treatment.

Belt dryer for peanut main structure

The main components include a mesh belt, transmission device, air inlet pipe, air outlet pipe, circulating fan, and so on.