Coated peanuts, also known as sugar-coated peanuts or flavored peanuts, are snacks coated with sugar powder, seasoning powder, or chocolate powder. They are usually divided into two types: rough-coated peanuts and smooth-coated peanuts.

With an attractive appearance and a crispy texture, they are popular with consumers. Producing high-quality coated peanuts relies on a fully automatic coated peanut production line, in which each step—from raw material selection to packaging—uses dedicated machines and processes.

Next, we introduce the entire production process according to the production steps and machine sequence.

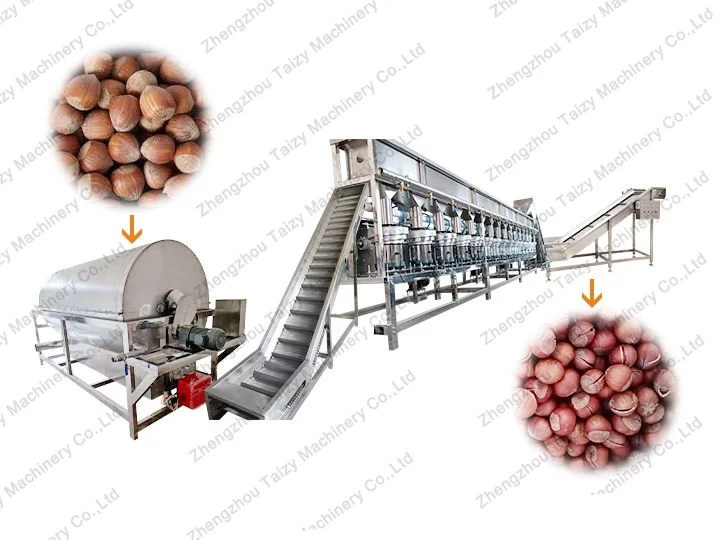

Raw Material Selection and Roasting

The first step in coated peanut production is selecting high-quality peanuts as raw materials. After entering the production line, the peanuts are roasted to remove moisture, enhance aroma and taste, and reduce breakage.

Equipment: Peanut Roasting Machine

- Drum-type design ensures even heating and prevents burning

- Moisture can be reduced to below 5%

- Heating options include electric heating, gas heating, or coal heating

Peanut Skin Removal

After roasting, the peanuts enter a dry-type peeling machine, which separates the kernels from the skins. The peeling rate can reach over 96%, providing a good basis for uniform coating.

Equipment: Dry-Type Peanut Peeling Machine

- Capacity: Approx. 200–250 kg/h

- Compact structure and easy operation

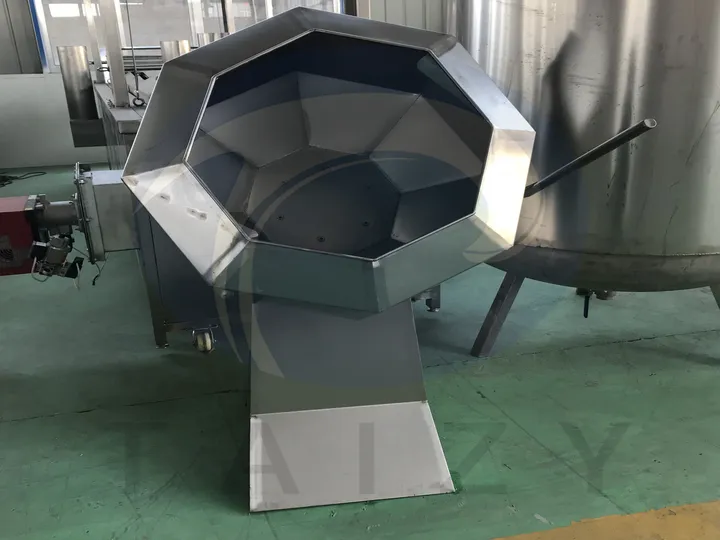

Coating (Powder Coating)

The peeled peanuts enter a peanut coating machine or coating-forming machine. Under centrifugal force, the peanuts tumble continuously while sugar powder or seasoning powder is added gradually, ensuring an even coating on each peanut.

Equipment: Peanut Coating Machine

- Internal rolling and friction mix peanuts with powder evenly

- Coating thickness is controllable to ensure a smooth appearance

- A high automation level reduces manual intervention

Coating Fixing by Baking

After coating, the peanuts enter a swing roasting machine for baking. Heating fixes the sugar or seasoning coating, making it firm and crispy.

Equipment: Peanut Swing Roasting Machine

- Easy operation, baking time about 15 minutes

- Electric heating or gas heating is optional

- The rotating drum ensures even and stable heating

Seasoning

For peanuts requiring additional flavors, they enter a peanut seasoning machine. Salt, chili powder, chocolate powder, or other seasonings are added to create diverse flavors.

Equipment: Peanut Seasoning Machine

- Can be connected to a spraying system or manual feeding

- Even mixing to prevent uneven seasoning

- Capacity: Approx. 300 kg/h

Cooling

After roasting and seasoning, the peanuts pass through a peanut cooling machine to reduce temperature. This allows the sugar coating to set, prevents sticking, and prepares the product for packaging.

Equipment: Peanut Cooling Machine

- Air cooling or air + storage combination

- Adjustable airflow for fast cooling

- Capacity: Approx. 200–300 kg/h

Automatic Packaging

After cooling, the peanuts enter a packaging machine for quantitative packing according to customer requirements. This ensures hygiene, neat appearance, and easy transportation and sales.

Equipment: Peanut Granule Packaging Machine

- Can package in bags, boxes, or jars

- Packing speed: 37–100 packs/min

- Adjustable filling range: 22–220 ml

Difference Between Smooth-Coated and Rough-Coated Peanuts

Smooth-Coated Peanuts:

- Multiple coating and polishing processes are used, with sugar or seasoning powders applied layer by layer evenly.

- After coating, the peanuts undergo polishing or glazing to achieve a shiny, smooth, and uniform surface.

- Suitable for high-appearance snacks such as sugar-coated peanuts, honey peanuts, and chocolate peanuts.

- Typically requires two peanut coating machines: one for coating and one for polishing.

Rough-Coated Peanuts:

- Coating process is simpler, usually coated once or twice, and the surface may feel slightly granular or rough.

- No polishing is applied; sugar or seasoning powder is directly fixed on the peanut surface.

- Commonly used for spicy, salty, or nut-based snacks where appearance is less critical.

Taizy offers complete peanut coating production lines

The production of coated peanuts is a complete process, from raw material selection, roasting, peeling, powder coating, baking, seasoning, and cooling to packaging. Each step uses dedicated equipment to control quality and efficiency.

Using Taizy’s fully automatic coated peanut production line not only saves labor and reduces costs but also ensures even coating and a crispy texture. It is suitable for peanuts, broad beans, cashews, macadamia nuts, and various other nut and legume snacks.