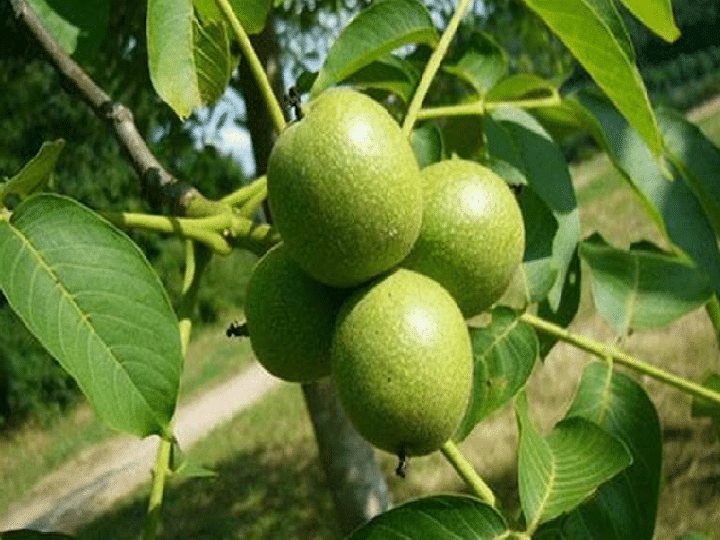

Since the harvest period of walnuts is relatively concentrated and the season is short after the walnut fruit is harvested, the outer green peel must be removed as soon as possible to keep the surface of the walnut hard shell clean, otherwise, the walnut kernel will be mildewed, which will seriously affect the walnut’s quality. Intrinsic quality, here are four ways to peel green walnuts.

Hand peeled green walnuts

The most primitive method is to peel the skin by hand, manually peel the rubber gloves on the belt, and use a stone or a knife to peel the skin. The disadvantages of this method are very obvious, time-consuming, and not suitable for mass production. A small amount of walnut processing cannot guarantee a clean appearance of the walnuts. During processing, the juice of the green walnut skin is also very difficult to clean, which will stain the hands.

Traditional retting method for peeling green walnuts

The traditional method of composting is to transport the collected green walnuts to a cool outdoor place in time and stack them according to the thickness of 50c. If the accumulation is too thick, the green walnuts will easily rot, and then the walnut piles are covered with 10cm of straw and weeds. The purpose is to increase the temperature in the walnut pile and accelerate the detachment of the walnut skin. After 4-6 days of accumulation, the walnut skin will expand and crack. At this time, tap the walnut shell with a wooden stick to help the walnut skin fall off. The walnut skin cracks and falls off easily. The reason why it cannot be directly exposed to the sun is that exposure can easily lead to discoloration and affect the quality of walnuts. In the process of accumulation, it should be noted that it should be avoided that the sewage generated by the accumulation of walnuts penetrates into the shell and reduces the commercial value of walnuts.

Ethephon peeling

The ethephon peeling method is to soak the freshly picked fruit with 5‰ ethephon solution for 0.5min or spray it with a sprayer. After spraying, it is necessary to stack the green walnuts for 50cm, maintain them at 30℃, and maintain the humidity at 80%- 90%, peeling and rinsing should be carried out in time after the walnut peeling machine. The probability of first-class fruit obtained by peeling this method accounts for 85%, and the productivity is relatively high.

Machine peeling walnuts

The green peeling walnut machine adopts free rotary cutting and peeling, the walnut enters the rotary cutting hob area, the high-speed hob starts to cut the green skin, and the walnut rolls freely at the same time so that all sides are cut by the hob. Continuously rolling out of the rotary cutting area, a small amount of unshaved green skin is cleaned by a wire brush and a semi-circular short-bristle brush cleaning rotary stick, and the clean walnuts are rolled out of the processing area and into the container. New walnuts are continuously fed, peeled and washed, and discharged. The distance between the grille and the rotary cutting hob can be adjusted automatically, and it can also be manually adjusted by adding or subtracting spacers according to the size of the walnut variety and the thickness of the green skin, so as to reduce the rate of shell breakage and improve the rate of net removal. Using machines to peel walnut green skin can improve the appearance quality and inner quality of walnut, reduce labor intensity and improve production efficiency. When the output is large, it is suitable to use the machine for processing, which can also shorten the processing time.

What are the walnut processing machines?

Walnut processing machines also include walnut shelling machines and walnut oil presses, etc. If you have walnut processing needs, you can contact us.