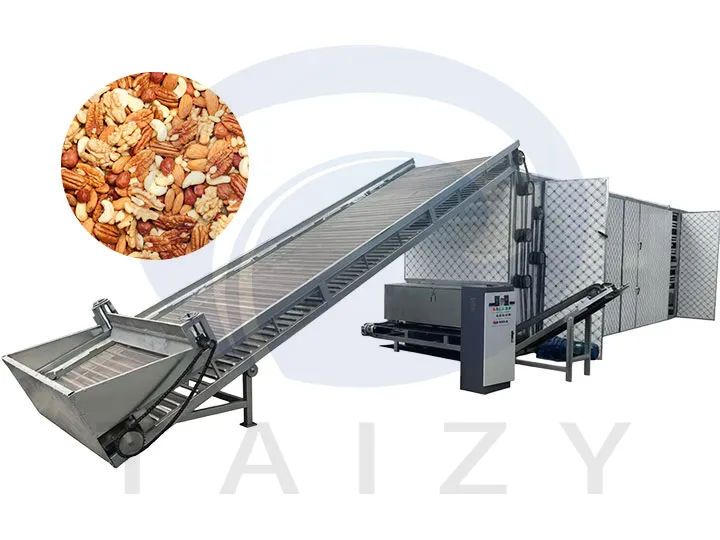

Mesh belt drying machine is one of the more common dryers, is a continuous production of drying equipment. The application range is very wide, can dry a variety of materials, widely welcomed by the major manufacturers.

Can be used for mesh belt drying machine material

In fact, mesh belt dryer can not only food processing, but it also widely used in chemical, pharmaceutical, building materials, electronics, and other industrial fields.

It is especially suitable for drying sheet, strip and granular materials.

Operating process

- First, turn on the main power supply and the motor switch to start the machine running.

- Open the steam valve so that the steam can enter the radiator.

- Open the fan control button above the control cabinet. And the hot air is then blown into the bottom of the mesh belt.

- When the equipment idles to the internal temperature to reach the set temperature. You can put the material into the material tank.

- Adjust the running speed of the mesh belt according to the actual material required to adjust the dryness.

- Turn on the dehumidifier, so that the wet air can be discharged from the machine in time.

- When the materials are dried. Turn off the switching power.

- Clean up the inside and outside of the mesh belt dryer and the mesh belt to ensure the normal operation of the machine.

Matters need attention

When pouring into the materials, it is necessary to pay attention to the uniform continuous pouring, to avoid the phenomenon that local materials cannot be dried.

The temperature of the equipment should determine according to the materials. Try not to use the same temperature for different materials.

The feed door must close and lock before the machine started. And the material must be removed after the dryer has completely stopped running.