At the beginning of 2022, we exported the peanut butter-making machine to Kenya. The customer imported it for the first time, so the whole conversation took a long time. Before purchasing the machine, the customer also rented a local peanut butter grinder for experiments and confirmed his own After the demand, the decision to purchase the demand is made. After the introduction of both parties and the understanding of the customer, the customer finally purchased the colloid mill and baking machine.

Details of peanut butter machines purchased by Kenyan customers

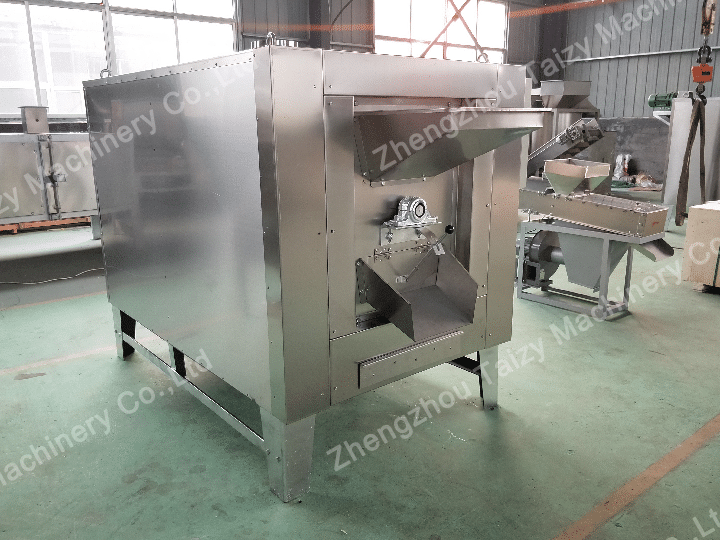

- Peanut Roaster

Since the customer is importing a machine for the first time, he first planned to buy a small peanut roasting machine. Peanut butter needs to be roasted before being ground. The ground peanut butter is more fragrant. It is also an important machine in peanut butter production.

Heating power: 15kw/380v

Transmission power: 0.75KW

Overall dimensions: 2300x1000x1450mm (plus electric cabinet, total width 1250)

Output: 50KG/H

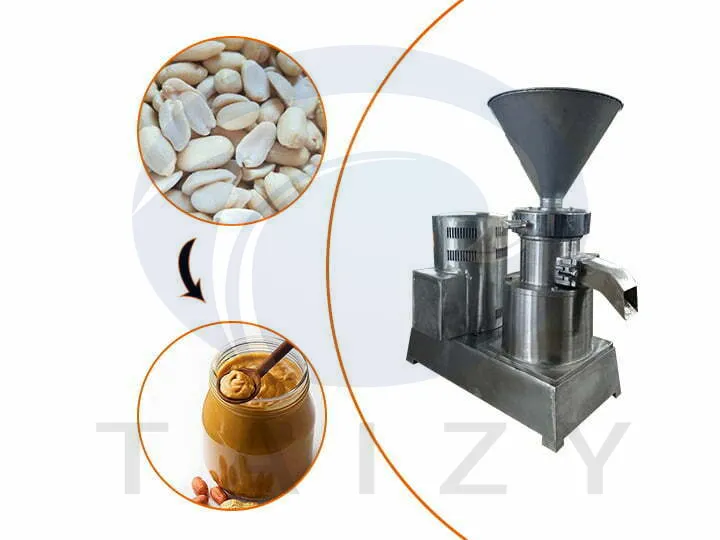

- Colloid mill

A colloid mill is mainly a machine that grinds peanut butter into the sauce. After machining, peanut butter of different fineness can be produced, and the type of colloid mill used is also different. In addition to the production of peanut butter, colloid mills can also be used to produce almond butter and chili sauce.

Power: 3KW (single phase, 220V)

Dimensions: 650x320x650

Weight: 70KG

Output: 60-80KG/H

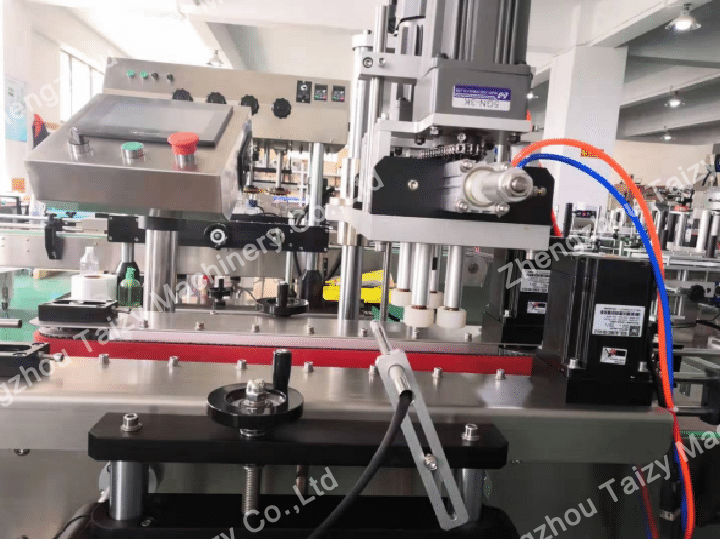

Customer inquiries about peanut butter filling

The Kenyan customer also consulted the peanut butter filling machine, but because it was the first time he imported, He wants to use the machine for a while after receiving the goods, before deciding whether to buy a peanut butter filling machine, so he did not buy it this time. The Kenyan customer mentioned the problem of the material used in the peanut butter packaging bottle in the inquiry. It is usually packed in glass bottles, why is this? There are many advantages to using peanut butter in a glass jar.

1. Economic reasons

The choice of what material jars need to consider economic reasons to ensure better profits. It is economical and environmentally friendly to use glass bottle filling, and customers can clearly see the color and fineness of peanut butter when they buy it after packaging.

2. Chemical reaction

Glass is silica, and silica is difficult to react with some oils, which can effectively ensure the shelf life of peanut butter.

3. shopping habit

The use of glass bottle filling has become a habitual method of use for consumers, which is also to cater to consumers’ preferences in the sales process.