The Automatic Peanut Butter Production Line is a machine that can produce peanut butter by peeling and grinding peanuts. This machine is a fully automatic production machine with very large output, but at the same time, we can also provide a machine with a smaller output. Peanut butter is a food that we often eat, and it is also liked by many people, so the market prospect of peanut butter is very broad. So how is peanut butter produced?

Production steps of automatic peanut butter production line

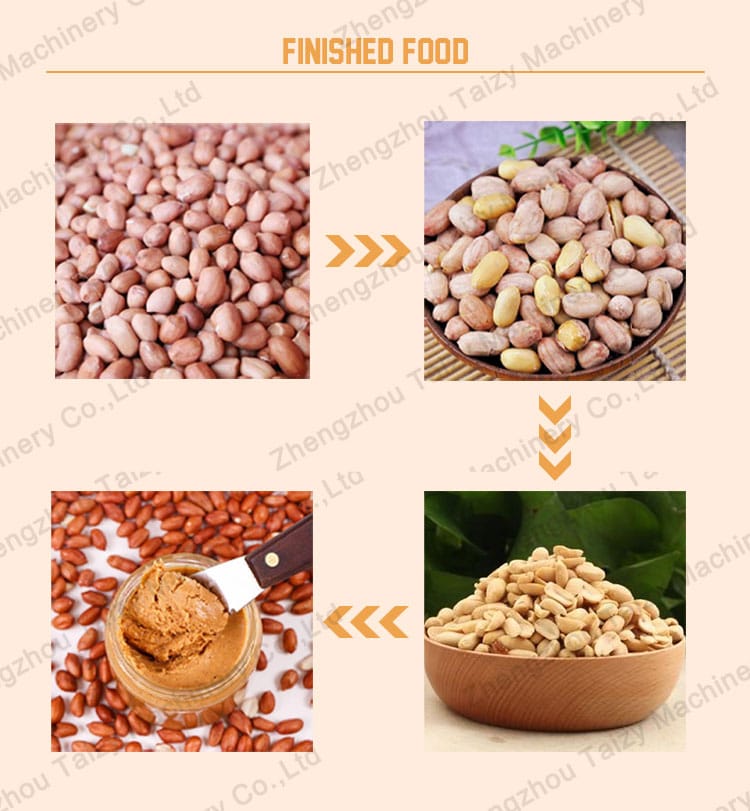

To produce peanut butter, we must first have good raw materials, and it is also important to choose good peanuts. Our production line starts to process peanuts with red skin. The steps for producing peanut butter are roasting, cooling, peeling, grinding, flavoring, and filling. So which machines are needed to complete these steps

Peanut Roasting Machine

The peanut roasting oven roasts peanuts. The raw material for roasting is peanuts with red skin. It takes 30 minutes to roast, and the roasting temperature can reach 180℃-200℃. Only at such a high temperature can the peanuts be roasted and matured quickly. What is more worth mentioning is that the fully automatic peanut butter production line is capable of baking and cooling the same batch of materials at the same time. Achieved continuous and uninterrupted production.

Groundnut peeling machine

The three-roll half-grain peeling machine is used to peel the peanuts after roasting. This machine has three important functions. First, it can peel the peanuts, and then it can split the peanuts in half, which is also beneficial in the next step. The peanut grinding process is faster. Finally, another important function is to remove the peanut germ. If the germ is not removed, the ground peanut butter will feel slightly bitter.

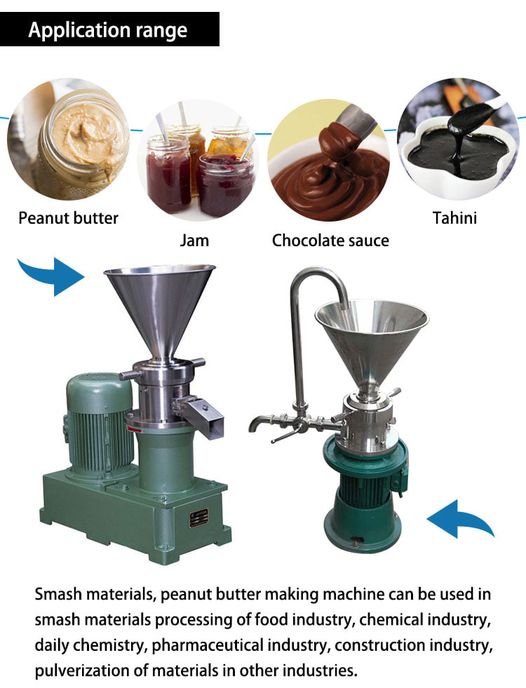

Colloid mill

The colloid mill is used to grind peanuts, but at the same time, the colloid mill can not only grind peanuts but also grind sesame seeds to make tahini, as well as some jams and grind cocoa beans to make the chocolate sauce.

Vacuum tank

If there are more bubbles, then after the vacuum tube is used to draw the vacuum, the peanut butter newspaper container can be lengthened, which is beneficial to the storage of peanut butter. Why is the vacuum tank used in the production of peanut butter? The reason is that there will inevitably be a lot of

Filling machine

Finally, the peanut butter is filled. In the fully automatic filling production line, of course, the filling is also very intelligent. The steps of the filling machine include bottle unscramble, filling, capping, and labeling. Through these steps, the peanut butter produced can be sold directly.

Features of the automatic production line

The output is large and the production efficiency is high. Automated production saves manpower. Compared with semi-automatic production lines, what are the differences? There is a detailed description in another article on the website.

Video of automatic peanut butter production

FAQ

- What model does the peanut butter production line have?

There are fully automatic and semi-automatic

- 2. How is the fineness of peanut butter

The fineness of peanut butter can be selected, there are two kinds of coarse grinding and fine grinding. The colloid mill used when grinding peanuts will be different.

- 3. Will the production process of tahini and peanut butter be different?

The production process of sesame sauce and peanut butter is basically the same, but the baking temperature of the baking oven and the outlet setting of the baking oven will be different

- 4. What is the maximum output

The maximum can reach 1kg/h