The macadamia nut processing line is a complete system designed to separate macadamia nuts into shells and kernels. It mainly consists of a macadamia nut rotary drum grading machine, shelling machine, shell–kernel separation machine, and kernel grading machine. The line enables a full-process operation, including nut grading, shell cracking, shell–kernel separation, and kernel grading.

Due to the macadamia nut shell being relatively hard, the open shell has become a major problem for people, coupled with the current fast-paced society and high pressure. People think nutrition is more important, so buying shelled macadamia nuts has become the trend of today’s society.

This production line has a capacity of 1–3 tons per hour, with a daily output of 8–24 tons. All parts in contact with food materials are made of stainless steel, while other components are constructed from carbon steel. The entire line complies with food safety standards in most countries worldwide.

Macadamia’s production line adopts scientific processes, which can ensure the quality of the product at the same time improve production efficiency and reducing labor costs.

Applicable Raw Materials

- Macadamia nuts

- In-shell almonds

- Hazelnuts

- Peach pits

- Other similar nuts, such as walnuts, cashews, and Brazil nuts (depending on the machine’s adjustment settings)

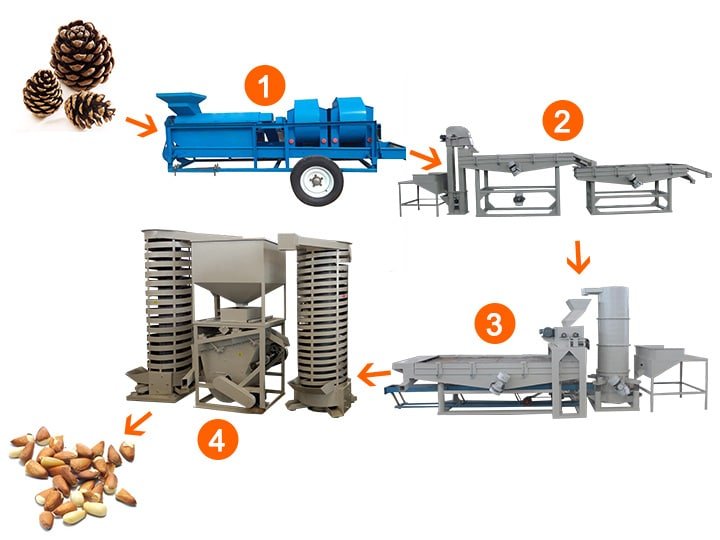

Macadamia Nut Production Line – Processing Flow

The macadamia nut processing line typically includes raw material grading, shell cracking, shell–kernel separation, kernel grading, and packaging. The entire line operates with continuous and automated equipment, ensuring a high cracking rate and excellent kernel integrity while improving processing efficiency. This guarantees consistent quality and appearance of finished macadamia nuts, making it suitable for large-scale industrial production. Below is an introduction to the main machines.

Elevator Conveyor (Raw Material Feeding)

The elevator conveyor is used to lift and continuously feed raw macadamia nuts into the processing line. It features stable operation and gentle conveying, reducing nut damage while ensuring a uniform and continuous material supply to downstream equipment

Rotary Grading Drum

The rotary grading drum classifies macadamia nuts by size through perforated rotating screens. Accurate grading improves shelling efficiency and cracking consistency in subsequent processes, making it a key step for high-quality processing.

Storage Hopper

The storage hopper temporarily stores graded macadamia nuts and ensures steady, buffered feeding to the shelling machine. Its large capacity and smooth discharge help maintain continuous operation of the entire production line.

Macadamia Nut Shelling Machine

The macadamia nut shelling machine cracks the hard shells using optimized mechanical force. It delivers a high shelling rate with minimal kernel breakage, ensuring excellent kernel integrity and stable performance for industrial processing.

Collecting Conveyor

The collecting conveyor transports the cracked mixture of shells and kernels to the next processing stage. Designed for efficient and orderly material flow, it helps keep the line clean and reduces manual handling.

Shell–Kernel Separator

The shell–kernel separator separates kernels from shells based on differences in weight and aerodynamic properties. It achieves high separation efficiency and purity, providing clean kernels for further grading.

Kernel Grading Machine

The kernel grading machine sorts macadamia kernels by size and quality. This ensures uniform finished products that meet different market and packaging requirements, improving overall product value and consistency.

Features of Macadamia Nut Processing Line

- High Capacity – The production line can process 1–3 tons per hour, suitable for medium to large-scale processing plants.

- Fully Automated Continuous Operation – Conveyors, hoppers, shelling machines, separators, and grading machines work in coordination for seamless, automated processing.

- Efficient Shelling – The shelling machine is optimized to achieve a high cracking rate with minimal kernel breakage, ensuring kernel integrity.

- Precise Shell–Kernel Separation – The separator efficiently separates shells from kernels based on weight and airflow differences, producing high-purity kernels.

- Kernel Grading – Grading machines sort kernels by size and quality, ensuring uniform finished products.

- Food-Grade Durable Materials – Key components are made of SUS 304 stainless steel, meeting food hygiene standards and providing corrosion resistance and easy cleaning.

- Energy-Efficient and Low Maintenance – The system runs stably with low energy consumption, and maintenance and cleaning are convenient.

- High-Quality Finished Products – Finished kernels are intact, visually appealing, and have appropriate moisture content, ready for market sale.

- Suitable for Industrial Production – Ideal for medium to large-scale industrial processing, improving efficiency and economic benefits.

Wide Market for Macadamia Nuts

After shelling, macadamia nuts can be processed into different flavored snacks. With the increasing demand for healthy living, the global macadamia nut snacks market size is also showing rapid growth. According to Statista data, the global macadamia nut snacks market size was $25 billion in 2022 and is expected to reach $32 billion by 2025, at a CAGR of 7.2%. If you have subsequent packaging requirements, our company also has technically mature packaging machines. Please contact us.

1000-1500kg/h Macadamia Shelling Production Line – Case

Machine list

| No. | Equipment Name (English) | Quantity |

|---|---|---|

| 1 | Lifting Conveyor (Raw Material Feeding) | 1 unit |

| 2 | Rotary Grading Drum | 1 unit |

| 3 | Grading Machine Supporting Frame (High Type) | 1 set |

| 4 | Electromagnetic Quantitative Feeder | 3 units |

| 5 | Shelling Machine | 3 units |

| 6 | Shelling Machine Supporting Frame (High Type) | 3 sets |

| 7 | Collecting Conveyor | 1 unit |

| 8 | Lifting Conveyor (Feeding Shell–Kernel Separator) | 1 unit |

| 9 | Dual Variable-Frequency Shell–Kernel Separator | 2 units |

| 10 | Grading Machine | 1 unit |

| 11 | Type 30 Gravity Stone Remover | 1 unit |

| 12 | Conveyor for Defective Kernel Picking | 1 unit |

Machine Specifications

| No. | Equipment Name | Dimensions (L×W×H) / Other | Power | Voltage | Weight | Material |

|---|---|---|---|---|---|---|

| 1 | Feeding Elevator (Raw Material) | 3.5 × 0.7 × 5 m (Conveyor width 0.4 m, vertical height 3.5 m) | 0.75 kW | 380 V, 50 Hz, 3-phase | 150 kg | PVC belt, hopper 304 stainless steel |

| 2 | Rotary Drum Grading Machine | 5.5 × 1.1 × 2.5 m, 3 drums, 4 levels (screen holes 18/16/14 mm) | 2.2 kW | 380 V, 50 Hz, 3-phase | 2300 kg | Drum hopper 304 stainless steel, other parts carbon steel |

| 3 | Height-Adjusted Base | — | — | — | — | — |

| 4 | Electromagnetic Quantitative Feeding Hopper | 1 × 1 × 1.6 m | 0.05 kW | 380 V, 50 Hz, 3-phase | — | 304 stainless steel |

| 5 | Shelling Machine | 2100 × 900 × 1300 mm | 3 kW | 380 V, 50 Hz, 3-phase | 280 kg | 304 stainless steel |

| 6 | Conveyor Belt | 6 × 0.6 × 0.6 m | 0.75 kW, adjustable speed | 380 V, 50 Hz, 3-phase | — | PVC belt + 304 stainless steel |

| 7 | Feeding Elevator (to Shell–Kernel Separator) | 0.6 × 0.6 × 3 m | 0.75 kW | 380 V, 50 Hz, 3-phase | — | PVC belt + 304 stainless steel |

| 8 | Shell–Kernel Separator | 2.6 × 1.1 × 1.6 m | 1.5 kW | 380 V, 50 Hz, 3-phase | — | Screen/frame 304 stainless steel, other parts carbon steel |

| 9 | Conveyor Belt | 5 × 0.6 × 1.5 m | 0.75 kW | 380 V, 50 Hz, 3-phase | — | PVC belt + 304 stainless steel |

| 10 | Feeding Elevator (to Grading Machine) | 0.6 × 0.6 × 3 m | 1.1 kW | 380 V, 50 Hz, 3-phase | — | PVC belt + 304 stainless steel |

| 11 | Multi-Layer Kernel Grading Machine | 1500 × 800 × 2200 mm, 4 layers, 5 levels (16/14/12/10 mm) | 0.75 kW | 380 V, 50 Hz, 3-phase | — | Hopper/screen 304 stainless steel, transmission carbon steel |

| 12 | Electrical Control Cabinet | — | — | 380 V, 50 Hz, 3-phase | — | — |

Notes: For reference only. For more detailed information, please contact us.