In modern nut processing, the apricot kernel shelling machine is essential for high yield, efficiency, and intact kernels. It mainly separates shells from kernels through three key processes: power transmission, shell cracking by pressure, and screening and separation. This article explains its working principle and design features in detail.

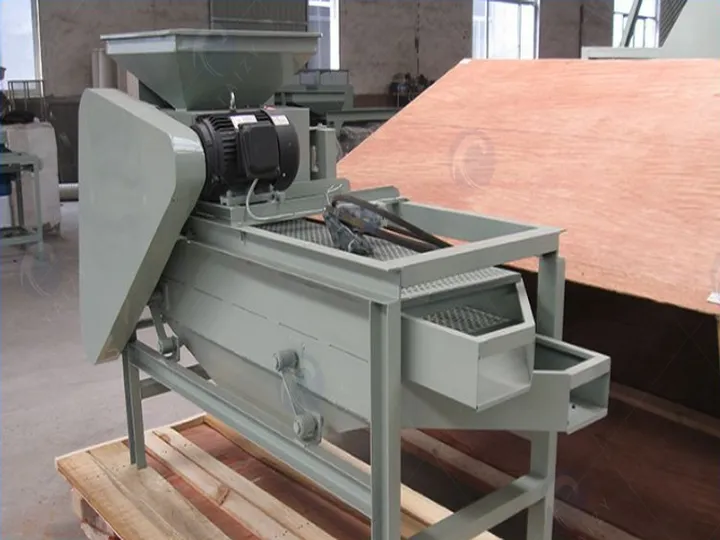

Power Transmission System

The apricot kernel shelling machine is usually powered by a single motor, which transfers energy to the rollers and eccentric mechanism via belts and chains, ensuring smooth operation. Common design features include:

- High-speed drive: The motor runs at high speed (over 1000 r/min), turning a small pulley that drives a large pulley and the main shaft, which powers the beating wheel or crushing rollers.

- Stable transmission: Chains or gears maintain steady movement of the rollers and shelling mechanism, ensuring even cracking and intact kernels.

This system is the foundation of efficient operation and is key to stable output and longer machine life.

Crushing and Shelling

Shelling is the core process of the apricot kernel shelling machine. It cracks the shells while keeping the kernels intact through pressing and rubbing. The process includes:

- Gap adjustment: The roller gap is set according to kernel size and hardness, ensuring the shell cracks without damaging the kernel.

- Pressing and rubbing: Kernels enter through the feed port and are pressed and rubbed by rotating rollers or crushing shafts. The rollers often have slanted grooves or dimples to increase friction, prevent slipping, and improve shelling efficiency and kernel integrity.

- Secondary shelling: Harder or smaller kernels that aren’t fully cracked on the first pass are screened and sent back for a second pressing to ensure complete shelling.

With proper gap adjustment and roller design, the machine achieves a balance of high shelling rate and low kernel damage.

Screening and Separation

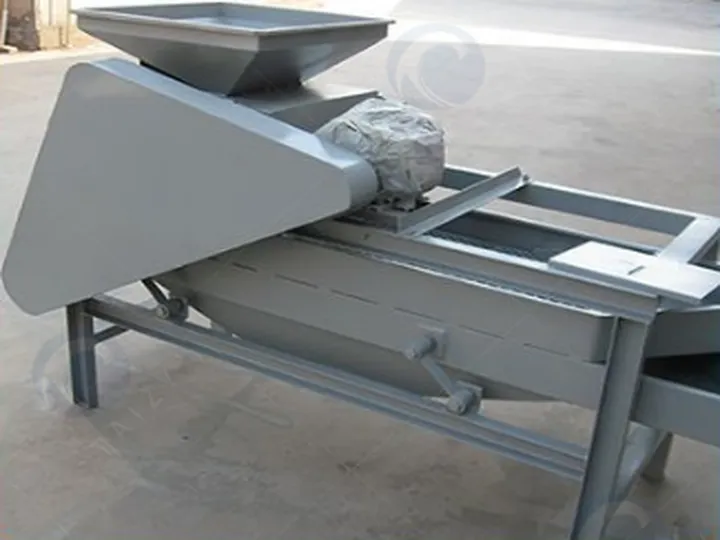

After shelling, the mixture contains shells, kernels, and debris, which are separated using a vibrating sieve:

- Upper sieve: With larger holes, it separates uncracked kernels (for secondary shelling) from shell-kernel mixtures.

- Lower sieve: With smaller holes, it separates shell fragments from intact shell-kernel mixtures. The whole kernels are then collected via a conveyor system.

The vibrating sieve uses a back-and-forth motion for automatic separation, reducing manual work and improving production efficiency.

Key Design Features

- High adaptability: Roller gaps are adjustable to handle kernels of different sizes and hardness.

- High efficiency, low damage: Grooved or dimpled rollers reduce kernel breakage, and the vibrating sieve automatically separates uncracked material.

- High automation: Screening and conveyor systems minimize manual work and ensure continuous production.

How to Achieve High Shelling Rate with Low Kernel Damage?

Before operating the apricot kernel shelling machine, ensure it is clean, all fasteners are secure, and roller gaps are set according to kernel size. Feed kernels evenly and slowly to prevent overloading. While discharging, monitor kernel integrity; if there are too many broken or uncracked kernels, adjust the roller gap or send the material for a second pass.

After production, clean the rollers, sieves, and conveyors, and check belts, chains, and motor operation. Keeping the machine dry and clean helps extend its service life and maintain stable shelling performance.