Dry type peanut skin peeling machine is specially used to remove the red outer skin of peanut kernels. The peanut tastes more delicious after removing the seed skin, which is widely loved by consumers. The peeling machine makes the shape of the peeling peanut complete and the peeling efficiency is high through a special process.

This peanut skin peeling machine has a capacity of 200–1000 kg/h. It peels well, with a cleanliness rate up to 96% and a half-kernel rate below 5%.

This machine removes peanut skins through mechanical rolling and friction, without the need for water. It is suitable for various peanuts, such as dry peanuts and crispy peanuts.

It is one of the most advanced dry-type peanut peeling devices. It runs stably, has a service life of over 10 years, can work with various machines, and is available in carbon steel or stainless steel according to customer needs.

Working Principle of dry type peanut skin peeling machine

Thw dry type peanut skin peeling machine uses mechanical rolling and friction to remove the skins from dried peanuts, without adding water or heating during the process. After drying, peanuts enter the peeling chamber through the feeding port, where rubber rollers are installed.

During operation, the peanuts are gently rubbed and pressed between the rollers, causing the skins to be removed while keeping the kernels whole and undamaged.

The rubber rollers have moderate hardness and elasticity, providing stable friction while preventing damage to the peanuts. After peeling, the mixture of kernels and skins is automatically separated by an air or screening system — the light peanut skins are blown away by airflow, and the clean, intact kernels are discharged from the outlet.

Unlike the wet type peanut skin peeling machine, the dry process does not involve soaking the peanuts. Instead, the dried peanuts are roasted first, because the roasted peanuts are easier to separate from the outer shell.

Peanuts enter the work area through the hopper, the red skin is removed by a high-speed rotating roller, and then sucked out by a fan and discharged to the outside of the machine, while peanut kernels are discharged through the front feed mouth.

Key advantages

High Peeling Rate, Low Broken Rate

Equipped with multiple fixed rubber rollers for synchronous rolling and peeling, the machine achieves a peeling rate of over 98%, ensuring peanuts remain whole with less than 5% broken kernels. No water is needed, preserving the natural flavor and extending storage life.

Multiple Models to Meet Different Capacities

Available in capacities from 200 kg/h to 1000 kg/h, suitable for small, medium, and large production lines. Users can select the model according to production needs for flexible and scalable operations.

Energy-Efficient and Cost-Saving

Uses purely mechanical friction for peeling. Each motor is only 0.55 kW, and the largest model (TZ-4) consumes less than 3 kW in total. Low energy consumption and high efficiency reduce operating costs, with an average power usage of less than 2 kWh per hour.

Automatic Separation System, Reduces Labor

Built-in air-flow separation system automatically separates peanut skins from kernels, minimizing manual sorting, keeping the production area clean, and improving overall efficiency.

Durable and Easy to Maintain

Core components, including wear-resistant fixed rubber rollers, are made of high-strength materials. The machine is easy to clean, maintain, and operate, with stable performance, low noise, and long service life.

Compact Structure, Small Footprint

The machine features a space-saving, well-designed layout, making installation convenient and suitable for various production environments, especially medium and small processing plants.

Wide Application and High Compatibility

Suitable for red-skinned peanuts, white-skinned peanuts, and various sizes of dry peanuts. Widely used in roasted peanut, peanut butter, oil, and snack food processing.

High-Quality Output, Supports Premium Production

Peanuts after peeling are uniform, whole, and naturally colored, ready for high-quality food production. Helps businesses improve product grade and market competitiveness.

Structure of dry type peanut skin peeling machine

The dry type peanut skin peeling machine mainly consists of the following parts:

- Feeding hopper – Peanuts are loaded here before entering the peeling chamber.

- Peeling chamber – The main working area, containing multiple rubber rollers that roll and rub peanuts to remove their skins.

- Rubber rollers – Have moderate hardness and elasticity to provide uniform friction without breaking the kernels.

- Separation system – Usually an air separation or screening device that separates the light peanut skins from the whole peanuts.

- Discharge outlet – Clean, peeled peanuts exit from here.

- Frame and casing – Provides stable support and protects internal components.

- Motor and transmission – Powers the rollers and ensures smooth operation.

Material description

| Part | Material & Steel Grade |

|---|---|

| Feeding hopper, machine body cover, rear motor cover, discharge outlet | Stainless steel 304 |

| Front cover plate | Acrylic (organic glass) |

| Pulley | Cast iron HT200 |

| Machine support frame | Carbon steel Q235 |

| Shafts and bearings | Carbon steel 45# |

| Internal partition plate | Stainless steel 304 |

| Partition fixing bolts and nuts | Galvanized steel |

Structural features

Main Shell & Partition Plate

Made of high-quality stainless steel, corrosion-resistant, easy to clean, and compliant with food safety standards.

Steel Roller Shaft

Crafted from 45# steel, precisely machined and dynamically balanced. The surface is coated with Grade 1 standard emery, providing stable friction and excellent peeling performance.

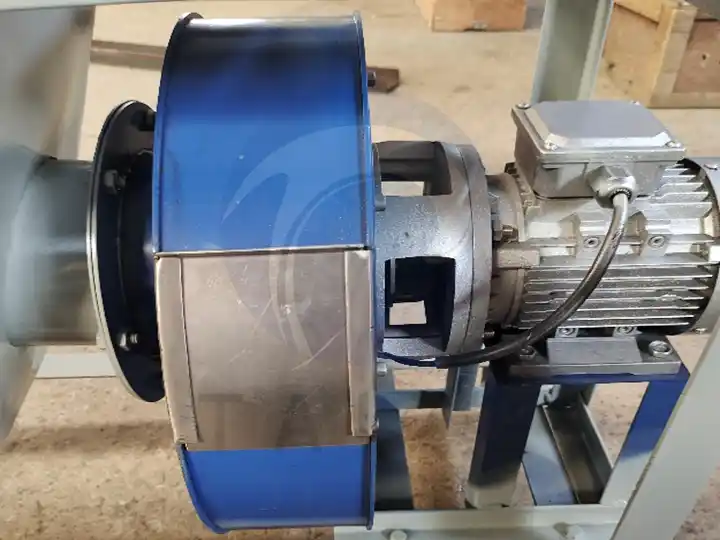

Impeller Design

Fewer blades for smoother airflow and faster discharge of peanut skins, improving separation efficiency.

Fan System

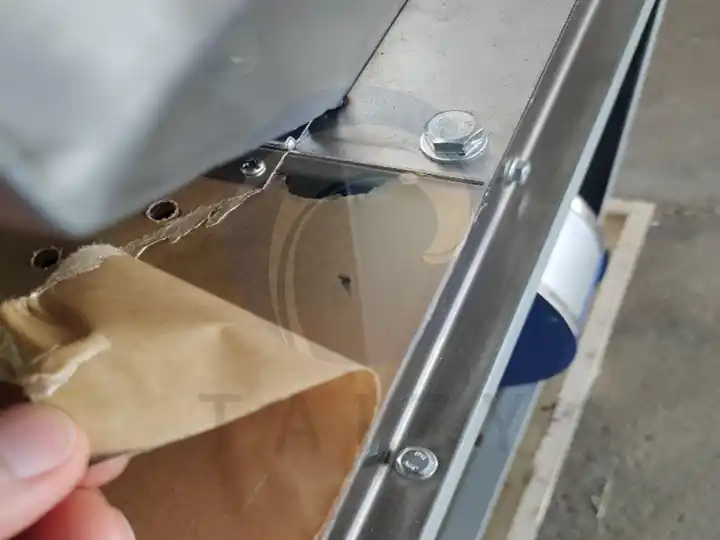

Equipped with an insert-type cleaning door for easy removal of residues and convenient maintenance.

Protective Cover

Made of acrylic (organic glass) with a protective film, offering safety, visibility, and a clean appearance.

Bearings

Fitted with national standard bearings, ensuring smooth, durable, and low-noise operation.

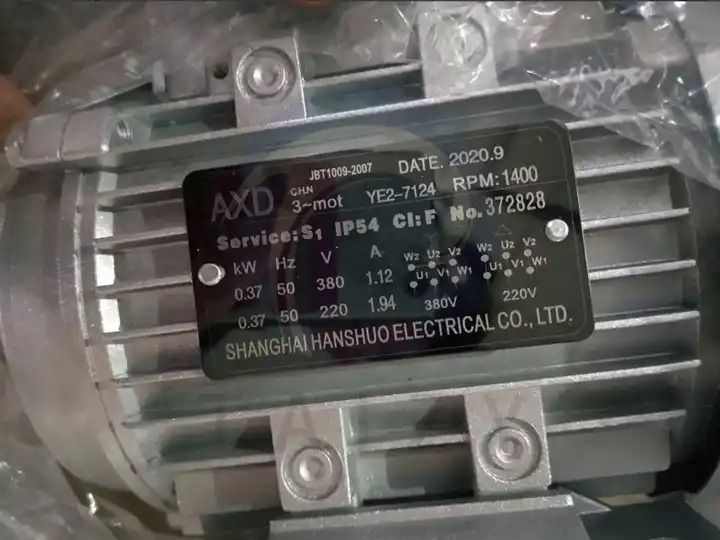

Motor

Uses an international brand motor, providing strong power, stable performance, and reliable continuous operation.

Technical parameters

| Model | Output | Motor power | Fan power | Voltage | Hz | Threshing performance | half-kernel rate | Size |

| TZ-1 | 200-300kg/h | 0.55kw | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*400*1100mm |

| TZ-2 | 400-500kg/h | 0.55kw*2 | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*700*1100mm |

| TZ-3 | 600-800kg/h | 0.55kw*3 | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*1000*1100mm |

| TZ-4 | 800-1000kg/h | 0.55kw*4 | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*1400*1100mm |

Working Process of dry type peanut peeling Machine

- Feeding – Dried peanuts enter the peeling chamber through the feeding hopper.

- Peeling with Steel Rollers – High-speed rotating steel rollers press the peanuts through the roller gap, generating uniform friction and pressure that removes the red skins while keeping the kernels intact.

- Separation – The mixture of peanut skins and kernels passes through an air or screening system. Lightweight skins are blown away by airflow, and clean, whole peanuts are discharged from the outlet.

- Discharge – The peeled, intact peanuts are collected, completing the peeling process.

Why choose taizy?

- Advanced Technology – Taizy’s dry type peanut peeling machine uses high-speed steel rollers with uniform friction and moderate pressure, ensuring efficient peeling while keeping peanut kernels intact.

- High Efficiency – The machine offers a capacity of 200–1000 kg/h, with a peeling rate up to 96% and a half-kernel rate below 5%, meeting various production needs.

- Durable and Reliable – Made of high-quality stainless steel, carbon steel, and steel rollers, the machine is strong, stable, and built to last for over 10 years.

- Customizable Design – Available in carbon steel or stainless steel versions and can be integrated with other peanut processing equipment.

- Energy-Saving & Eco-Friendly – Fully dry operation without water or heating, saving energy and keeping the process clean.

- Easy Operation & Maintenance – Compact structure, automatic separation of skins and kernels, easy to clean and maintain.

- Quality & Certification Assurance – Certified by ISO, CE, TUV, and SGS, ensuring high quality and compliance with international standards.

- After-Sales Guarantee – One-year warranty with professional technical support and spare parts service for worry-free operation.

FAQ

Don’t need it. However, it is recommended to use a peanut baking machine to bake peanuts before peeling, which can greatly improve the peeling rate of peanuts.

The degree of drying and water content of peanuts may affect the peeling effect to some extent.

Yes, we have a professional manufacturing factory, we can customize the peeling machine according to the actual needs of customers.