A semi-automatic peanut butter production line sits between a fully automated system and manual processing. It mechanises all key stages—such as peanut roasting, peeling, grinding, and mixing—replacing labour-intensive steps with efficient machinery. With operators assisting only in certain parts of the workflow, production efficiency increases significantly without requiring the high investment cost of a fully automated line, which can easily reach tens of thousands of dollars.

The Taizy semi-automatic peanut butter production line is designed for a capacity of 50–100 kg/h, making it ideal for small and medium-scale peanut butter producers. It offers high flexibility, easy operation, and simplified maintenance while meeting daily production needs.

To date, we have supplied peanut butter processing solutions to over 40 countries and regions. Our equipment has been exported to Italy, Canada, the Democratic Republic of the Congo, South Africa, and many other countries, receiving widespread positive feedback from customers.

The advantages of a semi-automatic peanut butter production line

Lower investment, faster return

Compared with fully automatic lines, it saves about 30%–50% of investment. Easy to maintain and operate, suitable for small and medium factories.

Flexible output (50–100 kg/h)

Supports 50–100 kg/h production. Highly scalable, can be upgraded to a fully automatic peanut butter production line in the future.

Easy operation, less labour

Key processes are mechanised, reducing manual work. Only a few workers are needed to run the whole line.

Stable product quality

Automatic grinding, even mixing, and precise filling ensure consistent taste and smooth texture.

Compact footprint, suitable for various sites

Compact layout fits small factories, startup workshops, or rural food processing projects.

Modular design for easy maintenance and upgrade

The semi-automatic peanut butter production line has a modular structure. Roasting, peeling, grinding, and filling machines can work independently or together. Users can add or replace machines according to orders, reducing maintenance costs and allowing future expansion or automation upgrades.

Main process flow of a peanut butter production line

The semi-automated peanut butter production line consists of the following seven machines.

Peanut shelling machine

The peanut sheller is mainly used to remove the outermost hard shell of peanuts, and the efficiency of the peanut shelling machine is very high. After putting the peanuts into the machine and turning on the power, the shells of the peanuts will be quickly opened. Then the shell and peanut kernel will be screened separately and be discharged from different discharge mouths. At the same time, the peanut sheller also has the advantages of high processing efficiency and no damage to nuts.

Technical parameters

| Model | Production | Power | Size | Weight | Peeling rate |

| TZ-200 | 200kg/h | gasoline engine 170F, motor/diesel engine 6 horsepower | 650*560*1000mm | 65KG | ≥98% |

| TZ-400 | 300-400kg/h | gasoline engine 170F, diesel engine 6-8 horsepower | 1200*700*1400mm | 130kg | ≥98% |

| TZ-800 | 600-800kg/h | gasoline engine 170F, diesel engine 8-10 horsepower | 1400*900*1600mm | 160KG | ≥98% |

Peanut roaster

A roasting machine is an essential machine in the peanut butter production line. There are many heating methods, including electric heating, gas heating, and so on. The operation principle of the peanut roaster is mainly to achieve uniform heating of materials through the rotation of the drum. The operator can also set the heating temperature in advance. After preheating, the peanuts, after removing the shell, can be poured into the cylinder body for roasting.

Technical parameters

| Model | TZ-MHK-1 | TZ-MHK-2 | TZ-MHK-3 | TZ-MHK-4 | TZ-MHK-5 |

| Transmission Power | 1.1KW | 2.2KW | 3.3KW | 4.4KW | 5.5KW |

| Heating Power | 22KW | 35KW | 45KW | 60KW | 75KW |

| Heating Gas (Kg) | 2-3 | 3-6 | 6-9 | 9-12 | 12-15 |

| Baked Yield | 80-120KG/H | 180-250KG/H | 280-350KG/H | 380-450KG/H | 500-650KG/H |

| Size (mm) | 3000*1200*1700 | 3000*2200*1700 | 3000*3300*1700 | 3000*4400*1700 | 3000*5500*1700 |

Peanut peeling machine

We usually use the dry peeling process to make peanut butter. The peanut peeling machine mainly uses the friction of the emery roller to remove the red seed coat of the peanut. Its peeling rate can reach 98% above at the same time.

Technical parameters

| Model | Output | Motor power | Fan power | Voltage | Hz | Threshing performance | half-kernel rate | Size |

| TZ-1 | 200-300kg/h | 0.55kw | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*400*1100mm |

| TZ-2 | 400-500kg/h | 0.55kw*2 | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*700*1100mm |

| TZ-3 | 600-800kg/h | 0.55kw*3 | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*1000*1100mm |

| TZ-4 | 800-1000kg/h | 0.55kw*4 | 0.37kw | 380V/220V | 50Hz | >98% | ≤5% | 1100*1400*1100mm |

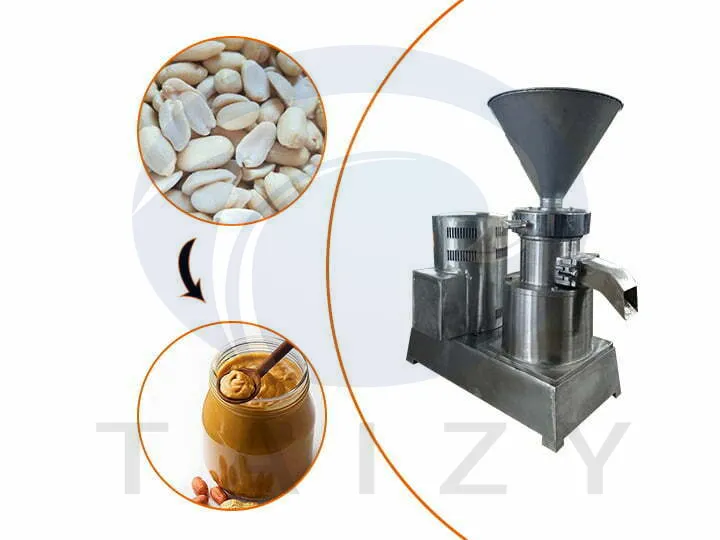

Peanut butter grinding machine

Under normal circumstances, the fineness of peanut butter ground by the grinding machine is 100-150 mesh. Which can also adjust according to the actual processing conditions. According to a lot of processing experiments, peanut butter grinding at 80-85℃ has the best taste.

| model | JM-50 | JM-85 | JM-130 |

| Material processing fineness (um) | 20-70 | 20-70 | 20-70 |

| Main motor power kW | 1.5 | 5.5 | 7.5 |

| output t/h | 0.2-0.8 | 0.2-2 | 0.2-3 |

| No-load revolutions r/min | 3000±100 | 3000±100 | 3000±100 |

| Outline dimensions of pipeline discharge in cm | 79*30*70 | 105*40*100 | 115*45*108 |

| Outlet dimensions of the square outlet in cm | 60*30*62 | 85*40*90 | 96*45*95 |

| Hopper height cm | 14 | 25 | 30 |

| Weight kg | 60 | 180 | 240 |

| water cooling system | Equipped with the cooling system | Equipped with the cooling system | Equipped with the cooling system |

Peanut butter agitation tank

The main purpose of the jar is to prevent the peanut butter from solidifying. But it can also be used as a seasoning process. After the peanut butter is ground by the milling machine and transported to the agitation tank, salt or sugar is added to flavour the peanut butter. An appropriate amount of stabiliser can be added to extend the shelf life of the peanut butter.

Vacuum degassing tank

After the previous step of mixing, peanut butter will form a certain number of bubbles, so a degassing tank is needed to degass. If the peanut butter contains too many bubbles, it will not be good for later storage of the peanut butter.

Peanut butter filling machine

Once the peanut butter is prepared, it is ready to be packaged. Normally, peanut butter is packaged by a filling machine. The filling machine adopts the pneumatic principle to realise the filling process; the filling amount can be adjusted. And the filling accuracy is generally between ±1-2%.

Application Scenarios and Industry Uses

The semi-automatic peanut butter production line is ideal for:

- Small and medium food processing factories

- Peanut farming cooperatives or joint processing workshops

- Trading companies building their own processing rooms

- Agricultural by-product processing projects

- Low-cost startup factories in overseas markets (Africa, Southeast Asia, South America, etc.)

- Businesses that want to start small and scale up gradually

Whether producing pure peanut butter, spicy peanut butter, chocolate peanut butter, or flavoured peanut butter, the semi-automatic line ensures stable and consistent quality output.

Routine maintenance and precautions of the semi-automatic peanut butter production line

1. Daily Cleaning

- Food-contact parts such as grinders, mixing tanks, and filling machines must be cleaned every day to prevent bacterial growth or flavour contamination.

- Use warm water and food-grade detergents; avoid corrosive chemicals.

- After cleaning the grinder, drain thoroughly or run it briefly without a load to remove water and prevent rust.

2. Regular Inspection of Wear Parts

- Check wear parts such as grinding plates, belts, screens, and seals regularly.

- If you notice uneven grinding, lower output, or increased noise, replace the grinding plates or inspect the bearings.

- Check the filler’s seals and valves to prevent leakage or unstable filling.

3. Lubrication of Mechanical Components

- Lubricate bearings, chains, and motor couplings according to the manufacturer’s recommendations.

- Do not use non-standard lubricants to avoid product contamination or equipment damage.

- Monitor motor temperature; stop the machine immediately if overheating occurs.

4. Electrical System Safety

- Before starting each day, ensure the control cabinet and wiring are dry.

- Check whether the emergency stop button works properly.

- Do not open the electrical cabinet while the machine is running.

5. Notes for Heating Equipment(For roasters and electric heating units)

- Check the temperature control system to avoid uneven heating or overheating.

- Clean dust and oil around the heating area to reduce fire risks.

- For gas heating, inspect gas lines, valves, and leakage points regularly.

6. Keep the Production Area Clean

- Keep the floor free from oil and peanut skin to avoid slipping and contamination.

- Store raw peanuts in a dry, ventilated area to prevent mould or moisture absorption.

- Separate cleaning tools from raw materials to avoid cross-contamination.

100 kg/h Peanut Butter Production Line Configuration List

| Equipment Name | Specification |

|---|---|

| Roaster | Model: TZR-100 Output: 100 kg/h Motor Power: 1.1 kW Electric Heating Power: 22.5 kW Temperature Range: 0–300 °C Control: Automatic thermostat control Material: Stainless steel Dimensions: 2900 × 1400 × 1650 mm |

| Peanut Peeling Machine | Capacity: 100–200 kg/h Power: 0.75 kW Dimensions: 1100 × 450 × 1100 mm |

| Peanut Butter Grinder (Butter Machine) | Model: TZ-110 Capacity: 80–100 kg/h Voltage: 380 V, 50 Hz Power: 7.5 kW Grinding Fineness: 2–100 μm Dimensions: 700 × 430 × 1000 mm |

| Filling Machine | Filling Range: 100–1000 ml Capacity: 400–500 bottles/h Configuration: Double-head filling |

| Air Compressor | Voltage: 380 V, 50 Hz, 3-phase Power: 3 kW |

| Capping Machine | Power: 0.37 kW Capacity: 20 pcs/min Suitable Bottle Height: 160–300 mm Dimensions: 630 × 240 × 940 mm |

| Semi-Automatic Labeling Machine | Power: 100 W Bottle Diameter: 15–120 mm Labeling Speed: 20–40 bottles/min Label Size: W26×L25 – W150×L300 mm Label Roll Inner Diameter: 75 mm Max. Label Roll Outer Diameter: 275 mm Machine Size: 650 × 345 × 450 mm |

Note: The above configuration is for reference only. Final machine selection and specifications should be determined based on your actual production requirements.

Why choose Taizy’s semi-automatic peanut butter production line machine?

Taizy (Shuliy’s Subsidiary Food Processing Factory) has been deeply involved in the food processing equipment industry for many years, with extensive experience and customer cases in peanut butter production lines. Our advantages include:

- 20+ years of R&D and manufacturing experience in peanut butter equipment

- Stable and durable machines designed for long continuous operation

- Stainless-steel key components, hygienic and corrosion-resistant

- Adjustable grinding fineness to match different taste requirements

- Fully customizable line: output, layout, and heating method can all be tailored

- Certified equipment (CE, ISO9001) for smooth export

- 1-year warranty and lifetime technical support

With mature technical solutions, Taizy has successfully delivered peanut butter production lines to many countries, including Africa, Thailand, Malaysia, Nigeria, Australia, and the Middle East.