Nut processing plant

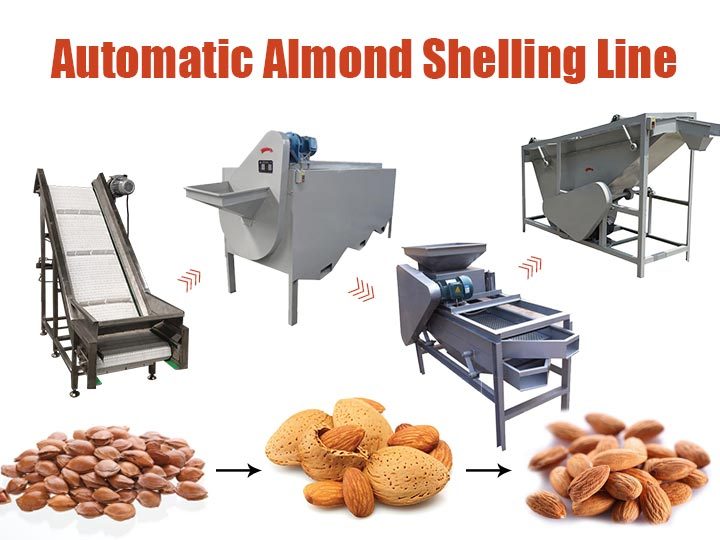

Almond Cracking and Shelling Machine | Hulled Almond Processing Line

Peanut Candy Production Line | Peanut Brittle Making Machine

Automatic Peanut Butter Production Line for Groundnut Paste Making

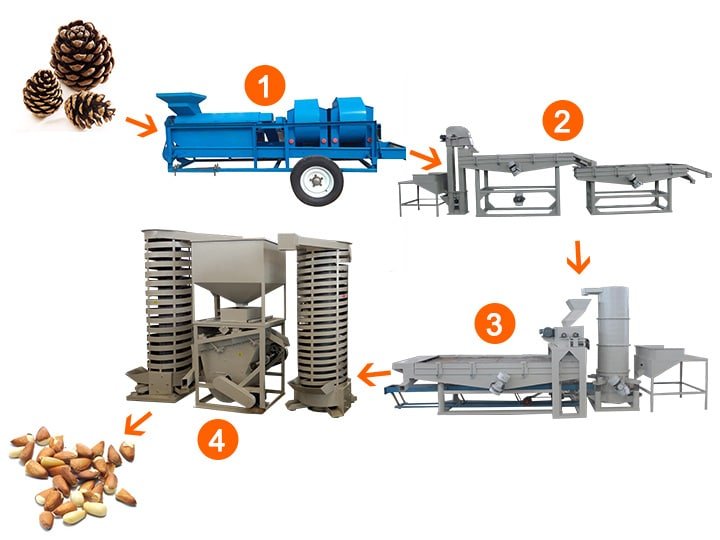

Pine Nut Processing Line | Pine Nut Production Equipment

Semi-automatic peanut butter production line

Cashew nut production line | cashew nut processing machine

Coated Peanut Production Line | Nut Coating Equipment

The cocoa bean processing plant