The peanut candy production line is a machine that produces peanut candy. The basic production steps are sugar boiling, raw material mixing, peanut candy molding, and packaging. This production line can make peanut candies, sesame candies, and melon seed candies, and the raw materials can be automatically matched without affecting the production process. The fully automated production line has high production efficiency and controllability.

Peanut Candy Production Video

Jacketed pot for food cooking mixer machine

The jacketed pot is a device used to melt and boil the sugar. Boiling sugar is an indispensable step for making peanut candy. The jacketed pot is equipped with a thermometer for easy temperature control. The machine has a cooking and mixing function, which is very convenient. The machine material is 304, an edible grade, and it is safe after heating for a long time. In addition, the machine is equipped with a special handle, and the pot body can be dumped, which is controlled by the handle of the machine. This machine can be used to boil sugar, heat raw materials, make chili sauce, melt chocolate sauce, etc. It is suitable for canteens, food processing plants, and other places.

The heating method of the Jacketed pot

This machine factory can be set to electric heating or gas heating during production and processing. Gas heating can be steam heating, liquefied gas heating, natural gas heating, or biogas heating. The diversification of heating methods makes the production and processing process more convenient. On the other hand, it can be selected in combination with the price of electricity and gas, thereby saving costs. The machine has different models from 100L to 600L

Blender for peanut candy production

The mixer is used to fully mix the boiled sugar with the peanuts. Since the sugar will harden after cooling, it is not possible to coat each peanut with sugar. Therefore, the mixer is designed with a heat preservation function. The characteristics of the mixer make double-layer heat preservation. The temperature is controllable. When mixing, during the production of peanut sugar, the corresponding raw materials should be added. For example, sesame and other nuts can also be added to peanut candy, and the manufacturer should prepare it in advance according to the recipe.

The mixing capacity also has different models, generally 50kg per batch. The material shell of the mixer is stainless steel, and the inside is PTFE, which has the advantages of high-temperature resistance, corrosion resistance, non-sticking, and non-deformation. The mixer also has a temperature monitoring device, which can detect the temperature at any time, and uses a double-layer device with a heat preservation function

| voltage | 380v/50HZ |

| powder | 2.5KW |

| size | 960*600*1200mm |

| weight | 150kg |

| capacity | 50kg/pot |

Peanut Brittle Forming Machine

| model | QY-SCX01 |

| Total power of host | 380V/50HZ 1.5kw 220/50HZ 2.5KW |

| Specification (mm) | 8000Mm (length)*1300Mm (length)*1200Mm (height) |

| Host quality | 1050kg |

| Yield | 50-500kg/h |

| Finished product weight | 5g-300g |

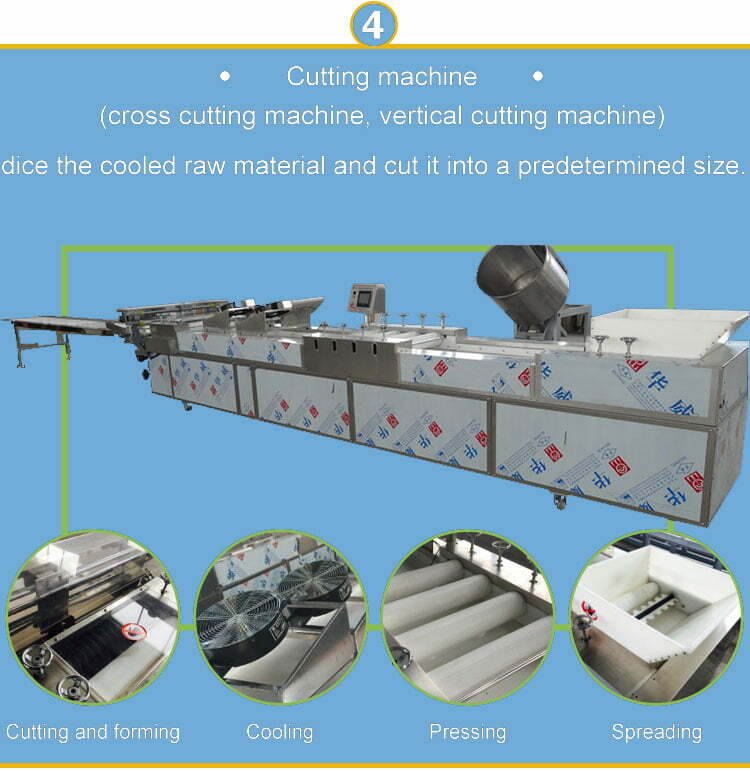

The peanut brittle molding machine is a machine that shapes mixed materials. The peanut forming machine includes three parts: rolling, forming, cutting, and cooling. Through these steps, the peanut candy is made into a block of peanut candy. When we eat peanut candy, the peanut candy has different sizes, so how do we control the growth of the peanut candy during the production process? What about width and height? We need to understand the principle of the peanut brittle forming machine.

How is peanut brittle formed?

Put the mixed material on the peanut brittle forming machine, the machine will roll it, because the sugar is added to the material, it will make the peanut brittle very easy to form. The peanut brittle forming machine usually has four pressure rollers to ensure the peanut The flatness of the sugar surface and the height of each pressing roller can be adjusted. These pressing rollers directly control the thickness of our peanut candy product, that is, the height of the peanut candy. Each wheel can be adjusted individually. You can adjust the thickness of the peanut candy gradually, or you can agree to set it to a height.

Peanut candy bar diced

The peanut candy we eat is not only different in taste, but the nuts added are also different in size, so the unique formula in production has formed a different peanut candy taste, and our peanut production machine can control the size of peanut candy, This can be combined with the requirements of peanut sugar production customers to carry out the design of the machine.

Peanut Candy Production Line details

Each manufacturer’s peanut candy has different sizes, more specifically, it has a different length, width,s, and height. Then the height of the peanut candy is adjusted by the height of the pressure roller of the peanut candy molding machine, so the manufacturer can It can be set it freely. In addition, the width of the conveyor belt and the distance between the cutters control the width and length of the peanut sugar forming machine. The width of the conveyor belt designed by the factory is 560mm. Perform cross-cutting, then a piece of peanut candy is basically formed.

If you want to use one machine to produce different peanut candies, or it is convenient to produce other candies in the future, then don’t worry, this machine can change the size of the peanut candies. The width of the peanut candies is determined by the spacing of the cutters. If you want to change the size, you only need to change a different knife and match the height of the cross-cutting knife and the pressure roller, and you can change the size of the peanut candy freely.

Peanut brittle Cooling

After forming and dicing the peanut brittle, it needs to be cooled to ensure that the shape of the peanut brittle is not damaged. The peanut brittle machine is equipped with a special fan to ensure that the peanut brittle molding machine can quickly cool down.

Groundnut Chikki Package

After the peanut candy is produced, it needs to be packed. This production line is equipped with an automated packaging machine to pack the peanut candy. After packaging, it can be sold.