At present, there are many names of oil press on the market. Including automatic oil press, multi-functional oil press, vacuum oil press, new oil press, fine filter oil press, etc., which belong to the spiral oil press, most of them are single spiral oil press. So what is the difference between a single screw oil press and a double screw oil press?

Introduction of single screw oil press

The single screw press consists of a horizontal pressing cage and a screw shaft rotating in the pressing cage. This simple structure greatly limits the efficiency of oil transportation in the crusher cage, and its crushing and mixing are not sufficient.

Working principle of single screw oil press

The oil embryo which has been steamed and fried is fed into the oil pressing part after the heat preservation and fine adjustment of moisture in the steamer. The pressing machine relies on the screw extrusion pressure and the press cage function to complete the pressing process of the embryo.

Disadvantage

It is mainly dependent on friction to realize material transportation. Which requires oil with a solid matrix similar to coarse fiber to produce friction. It becomes very sensitive to the temperature, moisture, and texture requirements of the pressed oil. And some small fluctuations will have a great impact on the pressing characteristics.

In the press of low oil content and the high fiber content of the oil. Sometimes the production of overheating, high energy consumption, product change, easy to produce feed is not smooth, smoothness or with the shaft rotation and blockage.

In addition, the current single screw oil press to hot press, basically should not be cold press.

Introduction of double screw oil press

Two opposite helical shafts in the press cage are engaged with each other in the press chamber to produce continuous driving force extrusion with the press cage to extrude the oil in the material embryo out.

The double-stage structure design of extremely high compression ratio. Obtain strong radial pressure so that the oil is only possible to press, the press is more thorough. Dry cake residual oil ratio than the single screw oil extractor oil yield is lower, oil crop oil yield is higher. Suitable for any oil crops hot and cold pressing.

Working principle

The oil in the material embryo is extruded out by using the extrusion pressure produced by the two opposite spiral axes in the press cage with the effect of the press cage. The whole oil pressing process from the material embryo into the press machine to the cake is continuous.

Take rapeseed as an example, the current single screw press is not suitable for cold pressing oil for rapeseed peeling and cold pressing. Therefore, in order to realize the cold pressing of rapeseed after peeling. It is necessary to enhance the propelling capacity of the material conveying screw of the oil press. Increase the pressing force and extend the pressing time.

Use the more common oil press

Now the oil pressing is the main single screw oil press. For single screw pressing technology, whether full pressing or pre-pressing, raw materials must be pretreated appropriately before pressing. Such as drying, peeling or peeling, crushing, blast-rolling and steaming, etc.

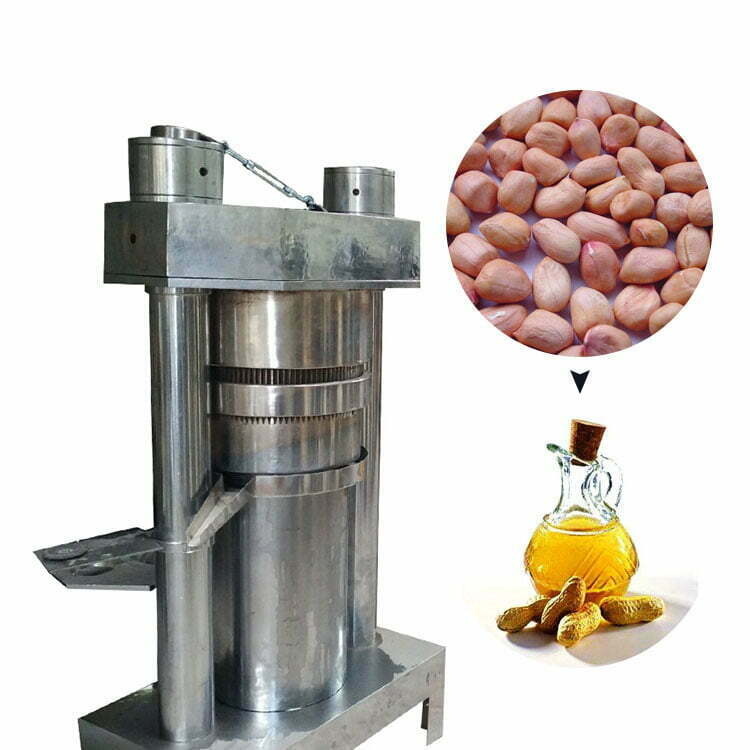

In addition, a more widely used oil press is the hydraulic oil press. Whether it is home or commercial, the extraction effect is very good.