Groundnut decorticator is professional equipment for removing peanut shells. It is widely used in the peanut manufacturing industry, which brings great convenience to peanut processing in the early stage. At the same time, it has the characteristics of high shell-removing efficiency and no damage to the peanut kernel. In addition, to meet the needs of different peanut production, the machine is also divided into a number of models for customers to choose from.

How the groundnut decorticator works

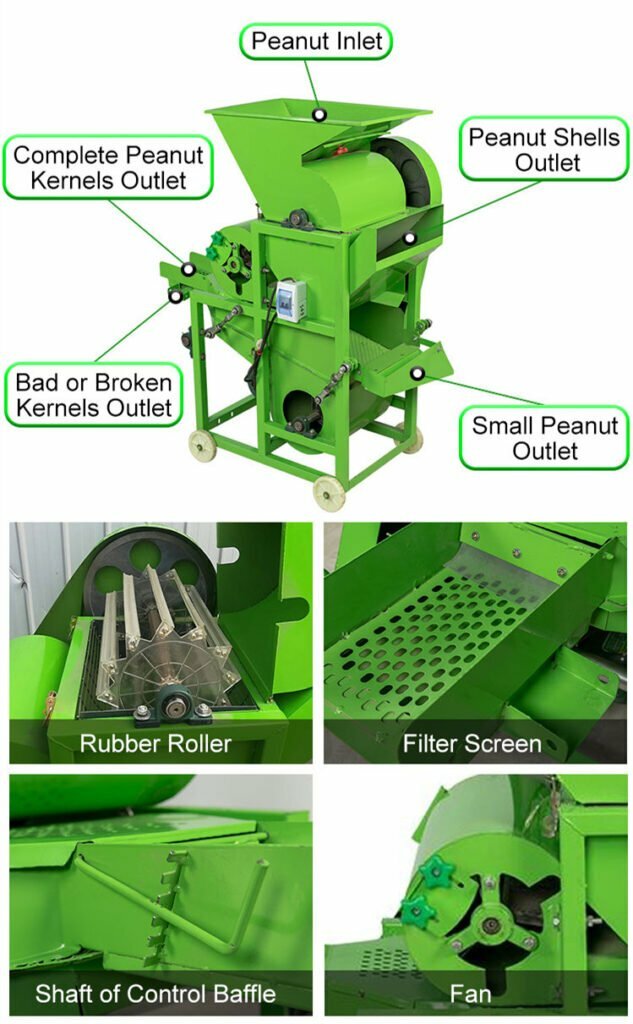

Groundnut decorticator main consists frame, fan, rotor, single-phase motor, screen, hopper, vibrating screen, triangular belt wheel, and transmission triangular belt, etc.

After starting the power supply for the machine running normally, peanuts, quantitative, uniform, continuous input into the hopper. Peanuts hit repeatedly, the action of friction of the rotor, the shell will be broken. Then peanut kernels and the broken peanut shells in the wind through the screen mesh. Under the action of the peanuts in the first threshing large aperture sieve. After screening, the replaceable become small hole mesh shell for the second time.

Finally, the peanut shell and kernels are blown out of the machine. The light peanut shell blew out of the body. And the peanut grains re-screened through a vibrating screen and discharged through the outlet.

Groundnut decorticator introduction and product features

- High productivity, peeling rate of more than 98%, while the operating environment is less pollution.

- The loss rate and breakage rate of peanut kernels are low.

- The groundnut decorticator equipped with a high-quality directional wheel and adopts a unique side mounting design to make it easy to move.

- Simple operation, a high degree of automation, compact size, efficient, and convenient.

- The peeling machine is simple in structure, easy to operate, easy to maintain, and low in power consumption.

Points of attention when using the decorticator

- We must make a thorough inspection of all parts of the cracking machine before use. Including whether the rotating parts are still flexible, and whether there is enough lubricating oil in each bearing. And ensure that the machine is placed on level ground.

- After the mechanical start, the steering of the mechanical rotor and the pointed opposite direction of the machine is consistent. So it is recommended that we can be before the formal use of the test, check whether it is normal.

- The operation should be evenly appropriate for the peanut, do not contain iron filings and rocks, and other debris.

- In addition, the voltage of a single-phase motor should reach its rated voltage under normal working conditions. So you should pay attention to the voltage problem before use.