Oil expeller is a kind of mechanical equipment widely used in edible oil extraction. Hydraulic oil expeller is one of the most common oil press. Also known as the new vertical hydraulic oil press, hydraulic oil machine, sesame oil machine. And hydraulic oil expeller also has the characteristics of simple operation, high oil yield, convenient maintenance.

Introduction of hydraulic oil expeller

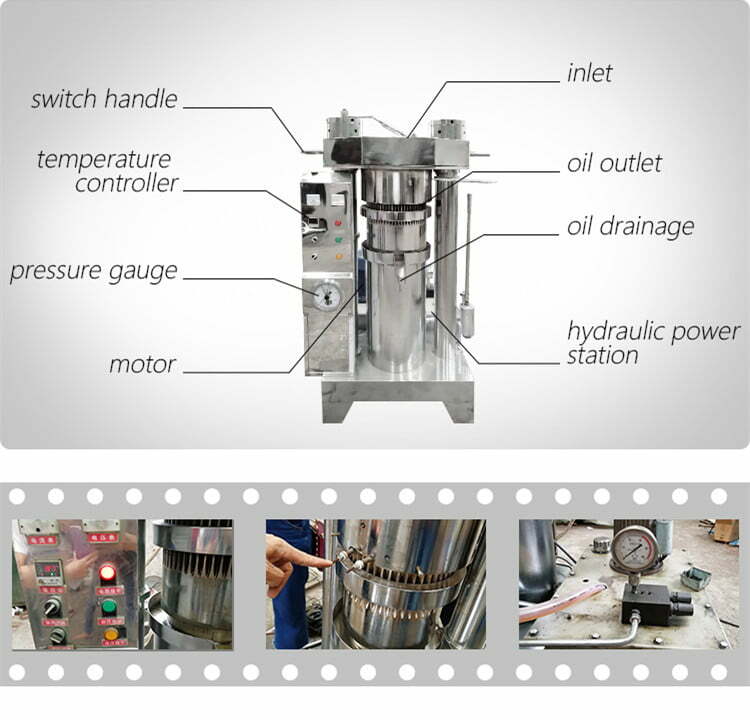

The hydraulic oil expeller mainly used for pressing oil crops. The main parts include piston, hydraulic cylinder, column, movable upper beam, base, oil pump, cylinder, electric heating ring, and automatic temperature control device, etc.

This pressing machine materials are made of high-quality metal materials. Thus improving the performance of the machine and ensuring the service life of the components.

The working principle of oil expeller

The hydraulic oil press is the hydraulic oil through the oil pump pressure transfer pressure. The press equipped with a temperature control device so that the oil in high pressure and high-temperature state of oil press machinery. There are two kinds of driving power sources of the oil pump, manual and electric. According to the way to apply pressure to the blank cake can be divided into vertical and horizontal.

An oil cylinder is fixed on the base of the electric hydraulic oil expeller. And then arrange a cylindrical piston in the cylinder. The upper part of the piston connected with the cake plate as a whole.

Press the blank a round cake, and the cake ring overlaid with 20-40 round cakes, which stacked between the cake plate and the top plate. The thin pad plate with holes used to separate the cake and the other cake. And drive the piston to the top to produce pressure and press the cake to produce oil.

After pressing, discharge the oil pump stops pressurizing, the piston drops, the slag cake. And then reload the material cake. In this way, the oil pressed intermittently repeatedly, and it takes about 2-5 hours for each pressing.

When used the electric oil pump, can form a circulating oil system and operate several hydraulic oil expellers at the same time.

The structure and working principle of the horizontal hydraulic oil expeller are basically the same as the vertical one. The equipment is easy to install, the oil flow is smooth, and the oil does not accumulate on the oil cake ring.

However, it covers a large area and needs to be equipped with a heavy hammer, pulley, or screw mechanism for extraction.

The advantages of hydraulic oil expeller

- The oil expeller can press the fried oil directly, and the whole process will be completed in about ten minutes. It is especially suitable for on-site pressing in oil workshop. Especially when pressing sesame seeds, it can not only let users see the whole process of pressing oil but also the oil has the characteristics of pure and fine oil quality, lasting fragrance, and so on.

- Reasonable design, compact structure. Also with ultra-high pressure piston pump and gear pump mutual compensation, large flow cartridge valve, hydraulic pressure rise fast, less pressure loss, with programmable controller electrical control, stable operation, small power consumption.

- The oil expeller is made of selected high-quality steel and refined. And each part of the pressing machine has been precisely calculated. The force point is reasonable, the pressure is uniform, and the rigidity is also reliable and firm, and durable.

- This kind of hydraulic oil expeller has uniform force in the press, high oil yield. And the net rate of oil can reach 98.8-99.2%, which makes the economic benefit higher.

- Adopt pressure-temperature preset and automatic control of the working process, which is also easy to operate and saves manpower effectively.

- The pressing machine combines the hydraulic pump station, electrical program control, and the frame organically. Which greatly facilitates handling and operation, and saves the floor space.