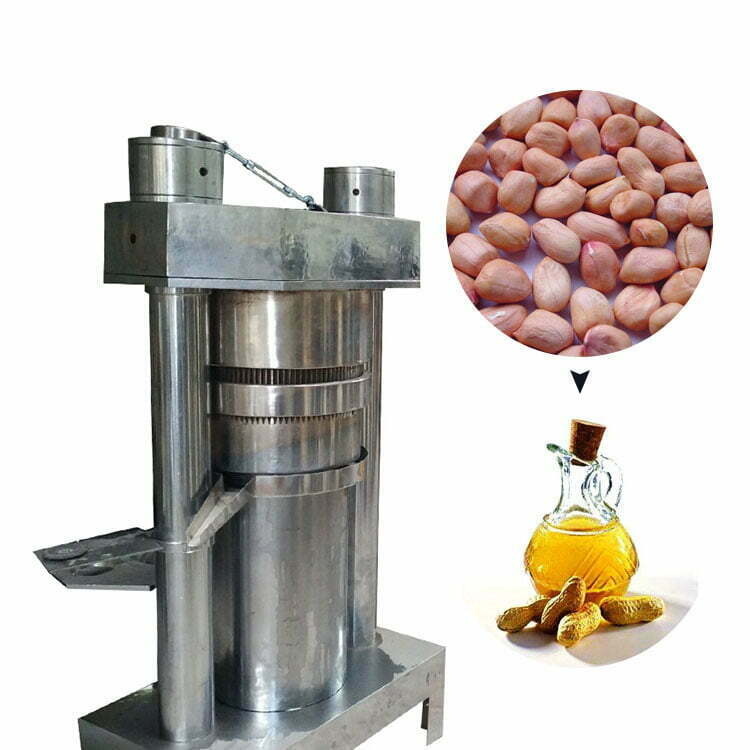

Nut oil extracting machine is a kind of hydraulic oil press because through the pure physical press way to press the material extraction, with high oil yield, and will not destroy the organic components in the oil. So it is the best choice for oil extraction from oil crops.

Nut oil extracting machine wide range of application

The scope of application of this hydraulic oil press is mainly the following categories:

- Hot pressed oil: sesame, peanut, rapeseed, wheat germ, corn germ, and so on.

- Cold-pressed oils: walnuts, pine nuts, almonds, olives, macadamia nuts, cocoa beans, camellia seeds, and so on.

- Seasoning category: Chinese prickly ash, tea seed, Perilla, and so on.

How to use the nut oil extracting machine

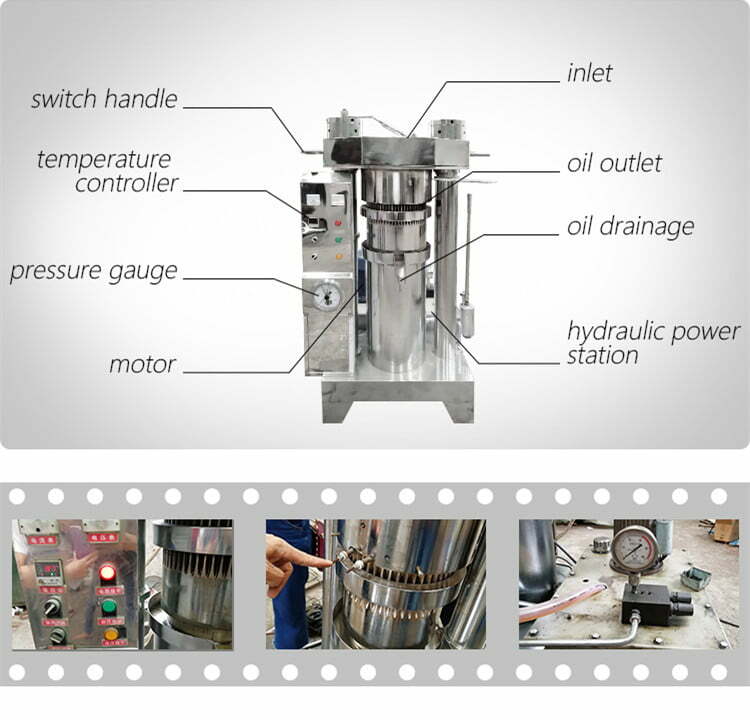

- When the nut oil extracting machine is idling, attention should be paid to whether the gear in the gearbox is engaged and whether the sound is normal, and whether the bearing parts and the motor are normal.

- Nut hydraulic oil press idling normal, then ready to press the material into the hopper.

- Pay attention to the start of the press when the feed can not be too fast, otherwise, the pressure in the press chamber suddenly increased, the press screw rotation is not moving, causing the press chamber blockage, and even the press cage rupture, major accidents.

- Therefore, when starting to press, the nut material should be evenly and slowly put into the hopper, so that the oil extracting can run.

- Depending on the material pressed, so you should choose the right way of hot pressing or cold pressing.

Characteristics of nut hydraulic oil press

- A wide range of pressing, so oil crops can be used;

- The use of physical pressing, will not destroy the organic components of oil crops, so the oil quality is good;

- The press operation is simple to operate, one person can operate multiple machines at the same time;

- Because of the high degree of automation, 8-10 minutes from the loading to the cake can be completed.

Type and parameters of oil press

| Model | TZ-150 | TZ-180 | TZ-230 | TZ-260 | TZ-320 |

| Size | 400*500*850 | 500*650*1050 | 600*850*1360 | 650*900*1450 | 800*1100*1550 |

| Weight(kg ) | 250 | 750 | 1050 | 1400 | 2000 |

| Maximum working pressure | 55 | 55 | 55 | 55 | 50 |

| Heating ring power | 2 | 2 | 2 | 2 | 2 |

| Control temperature of electric heating ring | 70-100 | 70-100 | 70-100 | 70-100 | 70-100 |

| Cylinder capacity | 2 | 4 | 8 | 11 | 15 |

| Cake diameter(mm) | 150 | 180 | 230 | 260 | 320 |