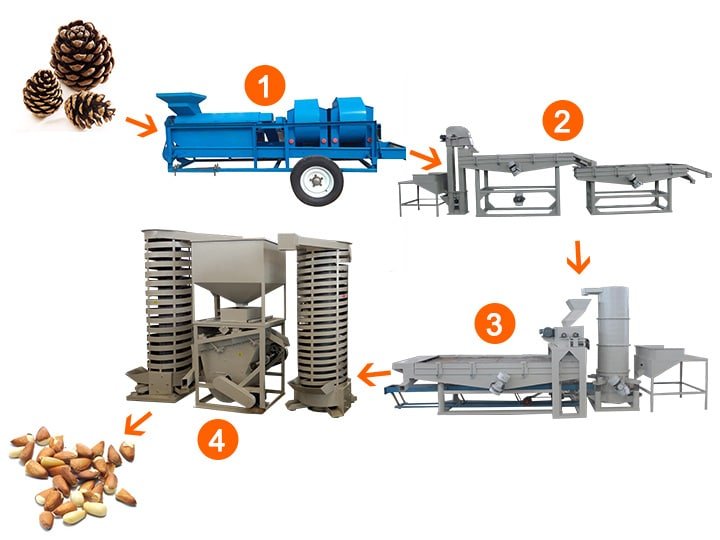

The pine nut production line is the entire process of picking pine nuts from the tree to obtain pine cones, and then processing them into pine nuts. It includes four steps of tower removal, grading, shelling, and separation of shells and kernels. After several machine processing, white and tender pine nuts can be obtained. These processes are necessary for preproduction and processing.

Types of pine nuts

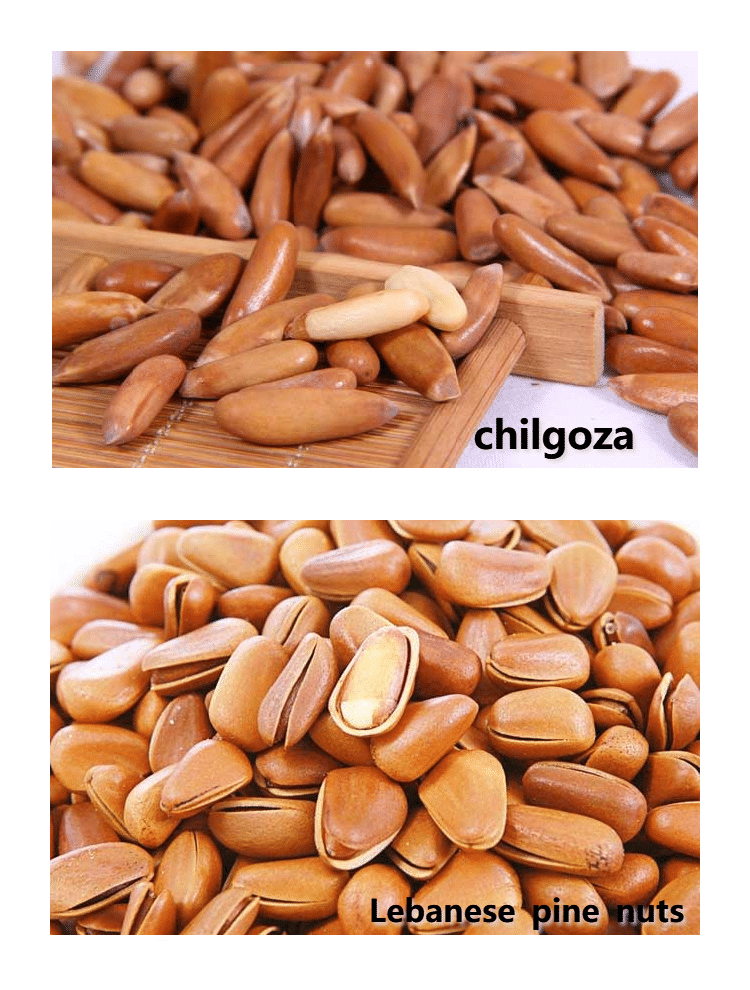

There are two main types of pine nuts. One is Lebanese pine nuts with hard shells. This pine nut is also called northeastern pine nut or red pine nut. The appearance of this pine nut is teardrop-like and has very good medicinal value. It can also be cooked or used in bread as a snack. They are all very good raw materials. The other is Pakistani pine nuts with a less rigid shell. Also known as chilgoza. This pine nut has a slender shape and high nutritional value. And it is even eaten as a snack. Due to the different appearance and hardness of the shell, the machine selected for processing is also different.

Lebanon pine nut processing line

Pine nut tower machine

Pine nut tower machines can remove the pine nuts from the pine cone. Since the pine cones are picked manually and are not fully mature machines, they need to be air-dried after they are taken off. The pine cones can be put in after they are mature and dry. It is processed in the tower crane. After being put into the machine, the pine nuts quickly fall off from the pine tower, and the machine collects the pine nuts, so you can enter the next operation.

Pine nut grading machine

The pine nut grading machine can classify the pine nuts according to their size of the pine nuts. The working principle of the classifier is that the classifier has a multi-layer mesh screen. The small holes of different sizes on the mesh screen help us to divide the pine nuts into different grades. And the price of different grades of pine nuts is different. Dividing into different grades will help us to carry out future sales and later processing.

Pine nut shelling machine

Each pine nut has a tan shell, especially the Lebanese type of pine nut. The shell is relatively hard. To remove the shell of the pine nut in batches, a pine nut sheller is needed. The shell kernels of the pine nuts that pass through the dehulling machine will crack, but they will not separate automatically, and the next step of processing is required.

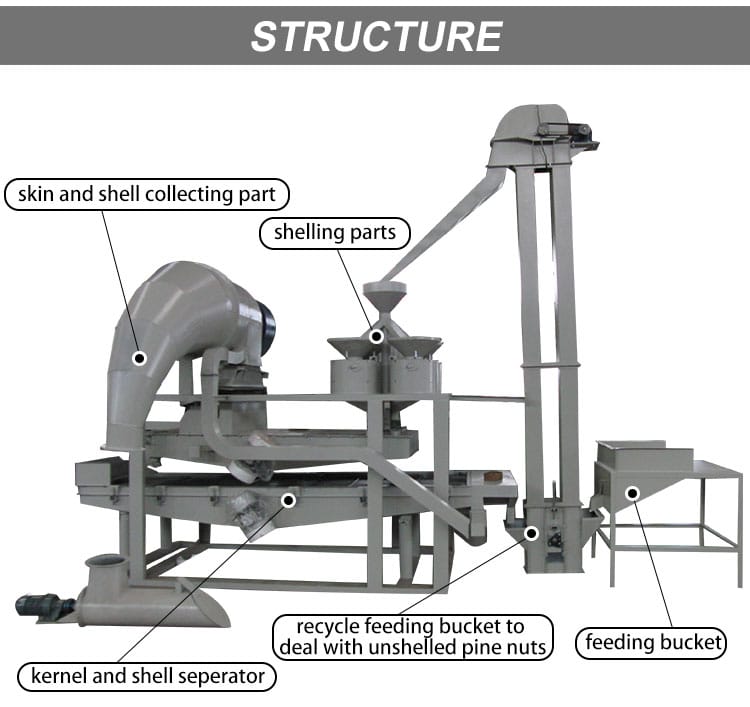

Pine nutshell and kernel separator

The function of the shell and kernel separator is to separate the shell of the cracked pine nut from the kernel, collect the kernels together, and then sell them later.

chilgoza pine nut processing

Generally speaking, the pine nut processing process is the same, that is, the pine nut is peeled, grated, dried, humidified, peeled, and the peel is separated, and then the white and tender pine nut can be obtained.

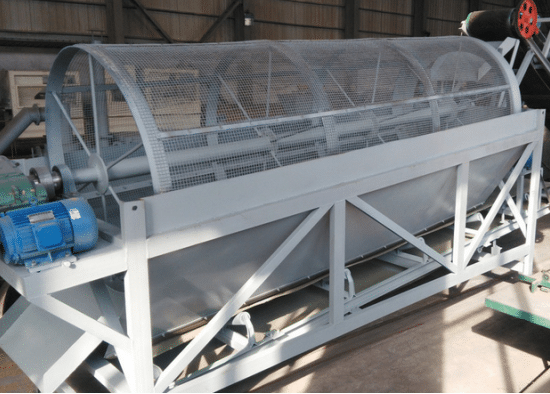

Cylindrical sieve for decontamination tower

The cylindrical sieve removes the tower through continuous rotation and constant friction between the pine cones. And the turret body has a lot of meshes, so the pine nuts can leak out from the air.

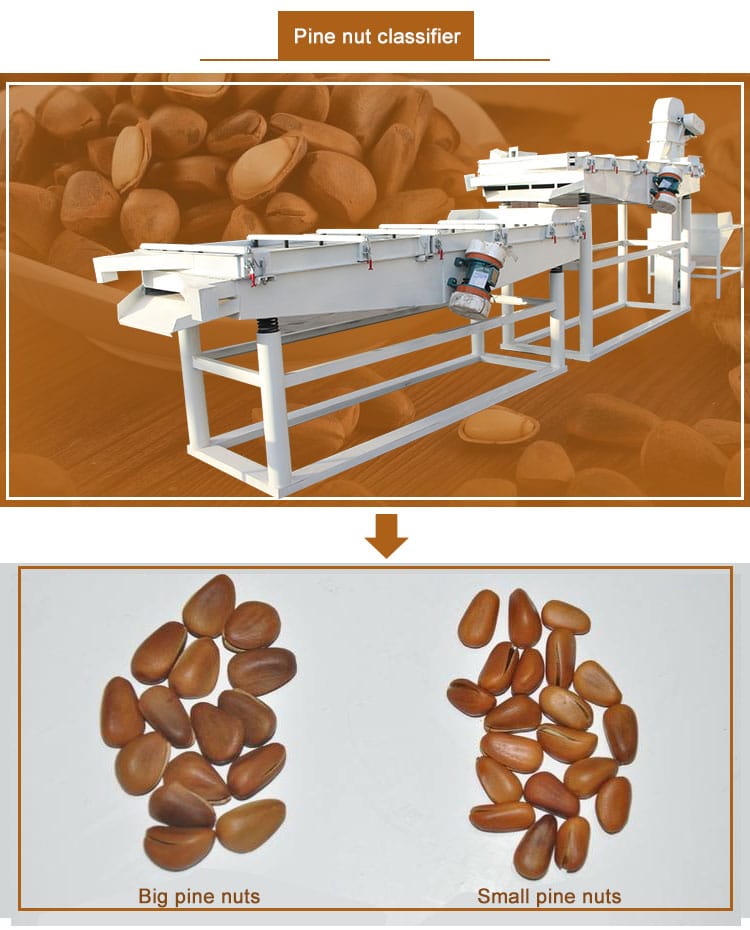

Pine nut grader

Like Lebanese pine nuts, Pakistan pine nuts also need to be graded. The pine nuts will be divided into several different grades through the grader. If you want to grade more grades, you can put the two machines together to form a chain. Multi-stage classifier

Pine nut peeling and separating machine

It is necessary to soak in water before peeling so that it will be easier to separate during peeling. The peeling machine has various functions. In addition to pine nut peels, it can also peel watermelon seeds, pumpkin buckwheat, and sorghum. The pine nuts that come out of the pine nut peeling machine can be sold directly or sold after baking