Crushed peanuts are used in many food processing, such as decoration, can be used for the decoration of cakes, and the decoration of snack skins. It can be added to ice cream or used as a condiment. For example, crushed peanuts will be added to the dip in a hot pot, and they will also be added when producing biscuits and cooking.

How do you crush peanuts quickly?

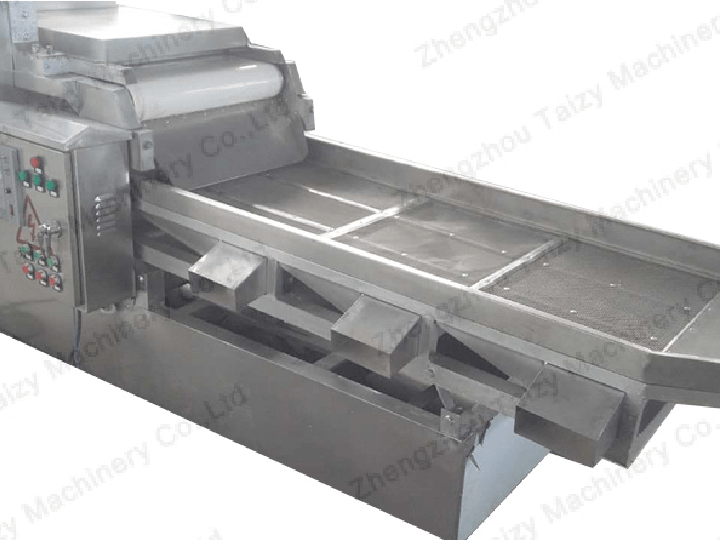

If it is used in a small amount at home, it is generally processed manually. If it is used in food processing, it needs to be processed by a machine. The peanut cutting machine can quickly and efficiently process peanut particles for processing and production.

How big can a peanut crusher cut

Due to the different uses of ground peanuts, the required sizes are also different. The conventional sizes are 1-3mm, 2-4mm, 3-5mm, and 4-8mm. The peanut cutting machine can adjust the size of peanut dicing by adjusting the handle of the machine. This machine adopts reciprocating knife type shredding and vibration classification, so as to achieve uniform shredding. There is no extrusion oil phenomenon, grading standards, and high yield. It is the ideal equipment for shredding at present.

What can the peanut dicing machine process?

In addition to cutting peanuts, the peanut dicing machine can also cut almonds, walnuts, hazelnuts, chestnut kernels, and basic common nuts. It is worth noting that if you cut peanuts, the effect of peeling in advance is better than that without peeling. Peanut peeling can be processed with a peanut peeling machine.

Advantages of Peanut crush machine

- Low noise. Low noise during processing by a peanut cutting machine

- Multifunctional. Can cut all kinds of nuts

- Cut evenly. Peanut kernels are cut evenly Peanut kernels are evenly sized

- High yield. Reduce extrusion oil phenomenon

- Use is long life. The equipment adopts high-quality materials to prolong the service life.