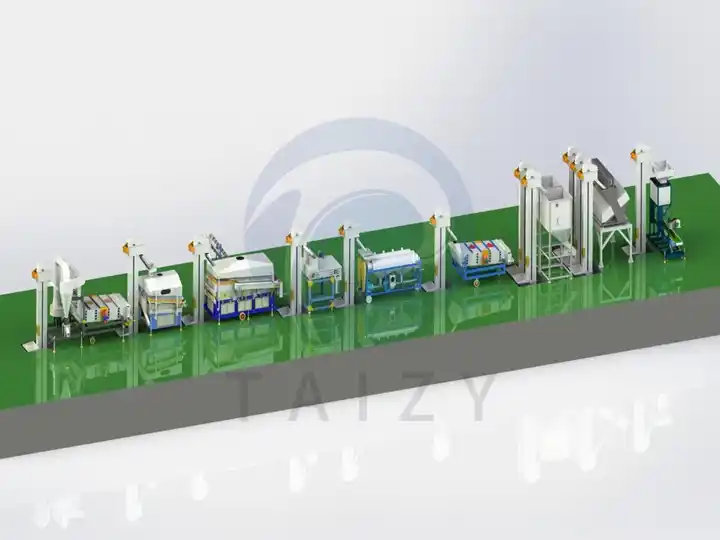

The cocoa bean cleaning line is a high-efficiency automated system designed for cocoa processing. It can remove impurities and dust, separate stones, perform density screening, magnetic separation, and grading, preparing the beans for further processing.

With efficient machine layout and high performance, Taizy can achieve a 99.9% impurity removal rate, eliminating stones, dust, and moldy beans.

This production line processes 4–5 tons of cocoa beans per hour, greatly improving production efficiency. Customized solutions are also available—feel free to contact us.

Cocoa Bean Cleaning and Sorting Process

This cocoa bean cleaning line has five main steps: pre-cleaning and dust removal, stone removal, density-based separation of bad beans and moldy beans, magnetic separation, and grading. Each step is carefully designed to remove impurities like dust, stones, leaves, and light husks, improving the purity and quality of the cocoa beans. Here is a brief description of each step:

- Pre-cleaning and Dust Removal: Raw cocoa beans first enter the pre-cleaning system. Air and screens remove dust, leaves, light husks, and small debris, providing a clean base for the next processes.

- Stone Removal: Using density separation, stones, sand, and other heavy impurities are removed, protecting the equipment and improving the product’s purity.

- Density-based Sorting: With air pressure and vibration, moldy, insect-damaged, and immature beans are separated from healthy beans, ensuring stable product quality.

- Magnetic Separation: High-strength magnets remove iron filings, nails, and other metal impurities, ensuring food safety and safe equipment operation.

- Grading: Finally, a multi-layer vibrating screen grades the cocoa beans by size, ensuring uniform distribution for baking and grinding.

Cocoa Bean Cleaning Line Structure

This production line mainly consists of five core machines: the cocoa bean pre-cleaner, stone remover, density separator, magnetic separator, and grader. Below is a detailed introduction to each.

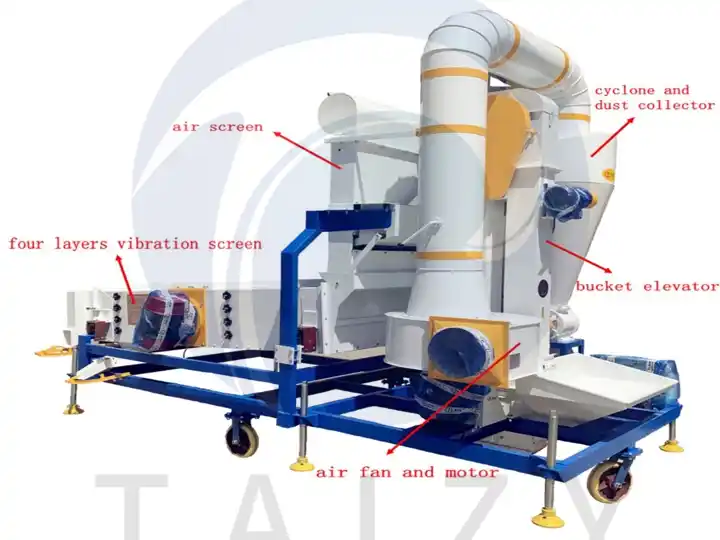

Cocoa Bean Pre-Cleaner – Dust and Impurity Removal

Function

This machine removes dust, husks, small fragments, and other light impurities from cocoa beans, while also screening out large and small debris for initial cleaning and grading. It is suitable for cocoa beans as well as various grains and seeds in pre-processing.

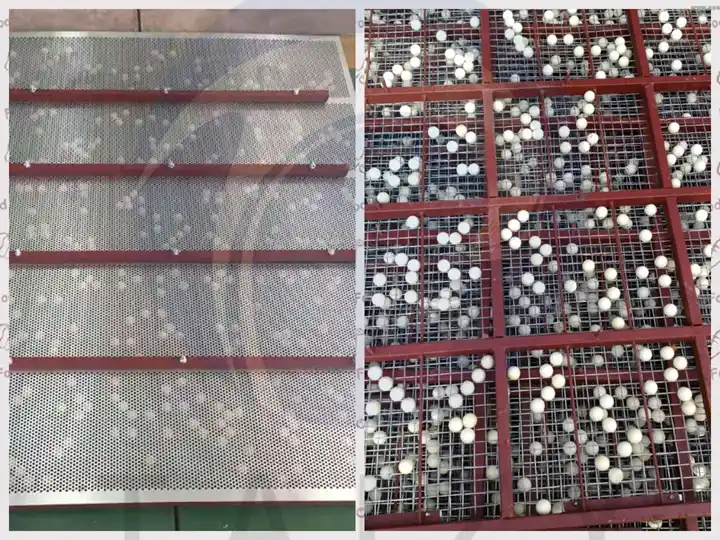

Working Principle

The raw material is lifted into the distribution box and evenly falls into the air separation chamber. Airflow carries away light impurities, which are collected by a cyclone dust collector. The remaining beans pass through a vibrating screen, where different mesh sizes separate large debris, small debris, and clean beans. By changing the screen, the machine can process different types of materials.

- Model: 5XZC-10DX

- Function: Feeding elevator, Air screen, Cyclone, Dust collector, Vibration screen

- Size (L×W×H): 4800 × 2500 × 3600 mm

- Weight: 2100 kg

- Capacity: 10 T/H (Based on process wheat)

- Cleaning rate: ≥98.5%

- Voltage: 380V (220V/440V need customized), 50/60 Hz, 3 phase

- Screen dimension: 2400 mm × 1500 mm × 4 layers

- Power: Total 10.5 kW

Cocoa Bean Stone Remover – Removing Stones and Particles

Function

The QSC-10 stone remover is used for cocoa beans, sesame, beans, corn, coffee beans, and other seeds to remove stones and soil. It can separate stones similar in size to the raw material, achieving up to 99.5% stone removal, ensuring clean raw material and improving the quality of subsequent processing.

Working Principle

Separation is based on the density difference between the beans and stones. Lightweight cocoa beans are suspended by airflow, while heavier stones stay on the stainless steel screen. The vibration table and airflow are finely adjusted, allowing efficient separation even when the density difference is small. Adjustable frequency allows precise tuning for different materials, ensuring effective stone removal.

- Model: QSC-10

- Size (L×W×H): 2550 × 2000 × 1600 mm

- Weight: 950 kg

- Capacity: 10 T/H (Based on process wheat)

- Cleaning rate: ≥99.5%

- Voltage: 380V (220V/440V need customized), 50/60 Hz, 3 phase

- Screen dimension: 2000 × 1800 mm

- Power: Total 7.35 kW

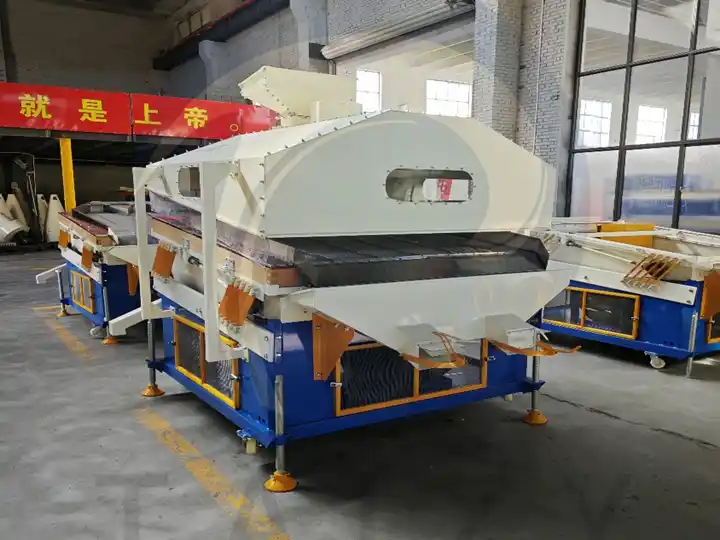

Cocoa Bean Density Separator – Premium Bean Selection

Function

The 5XZ-8 density separator is used for precise sorting of cocoa beans and various seeds. It removes low-quality beans, insect-damaged beans, moldy beans, beans with shells, stones, and other impurities. After processing, the beans’ thousand-grain weight, germination rate, cleanliness, and uniformity are greatly improved. The machine is flexible, easy to operate, portable, and reliable.

Working Principle

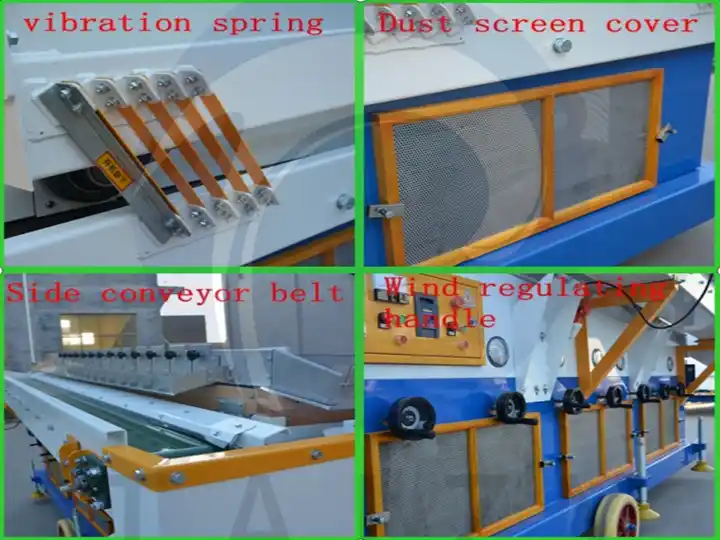

Raw material is fed into the gravity sorting table by a lifting machine. Seven adjustable air chambers and a vibrating table use air suspension and vibration to separate low-quality particles from good beans. The circulation sorting system further improves cleanliness, achieving over 99.8% sorting accuracy. Vibration frequency and air pressure can be finely adjusted for different materials, suitable for both large and small seeds.

- Model: 5XZ-8

- Size (L×W×H): 4100 × 2960 × 2935 mm

- Weight: 1700 kg

- Capacity: 8 T/H (Based on process wheat)

- Cleaning rate: ≥99.8%

- Voltage: 380V (220V/440V need customized), 50/60 Hz, 3 phase

- Screen dimension: 3300 × 1500 mm

- Power: Total 14.32 kW

Cocoa Bean Magnetic Separator – Removing Metal

Function

The 5CX-5 magnetic separator efficiently removes metal impurities and magnetic foreign objects from cocoa beans and other grains or seeds. It ensures raw material safety and cleanliness while protecting downstream equipment.

Working Principle

The material passes through magnetic rollers and a conveyor into a strong enclosed magnetic field. Metals and magnetic impurities respond differently from seeds, allowing separation. The magnetic roller has a strength of 18,000 Gauss and a width of 1,300 mm, ensuring high capacity and efficient separation. Drum speed can be adjusted with a frequency converter to handle different seed sizes.

- Model: 5CX-5

- Size (L×W×H): 2050 × 1850 × 2200 mm (main machine)

- Weight: 600 kg

- Capacity: 5 T/H

- Force: ≥18000 Gs

- Voltage: 380V (220V/440V need customized), 50/60 Hz, 3 phase

- Power: Total 1.5 kW

Cocoa Bean Grader – Size Classification

Function

The grader precisely sorts cocoa beans by size. Using multi-layer adjustable vibrating screens, beans are classified by length, width, or thickness, ensuring consistency and quality for further processing.

Working Principle

Cocoa beans pass through multiple layers of vibrating screens. The mesh size can be adjusted according to customer needs, allowing beans of different sizes to exit from different layers for high-precision grading.

- Power:2.25kw

- Weight:1000kg

- Dimension: 3400×2700×2700mm

Applications of Cocoa Bean Cleaning and Sorting Line

- Cocoa Processing Plants: Perform preliminary cleaning and grading to improve roasting and grinding efficiency.

- Food Raw Material Workshops: Clean and sort coffee beans, nuts, beans, and similar granular food materials.

- Cocoa Export Companies: Ensure cocoa beans meet export quality standards through thorough cleaning.

- Agricultural Cooperatives or Farms: Pre-process self-produced cocoa beans to increase their value.

- Trade and Logistics Centers: Quickly clean large volumes of imported or exported cocoa beans, reducing impurities during transport.

- Other Granular Material Processing: Can also be used for cleaning and grading coffee beans, peanuts, corn, grains, and similar materials.

Core Advantages of Taizy Cocoa Bean Cleaning Line

- High Efficiency in Impurity Removal: Multi-stage cleaning handles pre-cleaning, stone removal, density separation, magnetic separation, and grading, removing dust, leaves, light husks, stones, and metal impurities to improve bean purity.

- High-Precision Sorting: The density separator and grader accurately remove moldy, insect-damaged, and uneven-sized beans, ensuring consistent raw material quality.

- High Capacity and Efficiency: The line’s equipment is well-matched, handling 5–10 tons per hour. The circulation sorting system and wide magnetic separator ensure efficient large-scale production.

- Energy-Saving and Environmentally Friendly: Fully enclosed airways, cyclone dust removal, and optimized airflow reduce dust emissions, keep the workspace clean, and minimize raw material loss.

- Easy Operation: Mobile design with adjustable parameters for vibrating screens, air separation, magnetic separation, and grading adapts to different batches and bean sizes. Simple to operate and maintain.

- Safe and Reliable: High-quality motors and electrical components, with protective designs for the drive system, screens, and conveyors, ensure safe and stable production.

Cocoa Bean Cleaning and Sorting Line – Equipment List

| MODEL | TECHNICAL DATA |

|---|---|

| 5XZC-10DX PRE Cleaner | Power: 10.5 kW Weight: 2100 kg Dimension: 4800×2500×3600 mm |

| QSC-10 Stone Remover | Power: 7.35 kW Weight: 1200 kg Dimension: 2800×2000×1900 mm |

| 5XZ-8 Density Separator | Power: 14.32 kW Weight: 2200 kg Dimension: 4100×2300×1800 mm |

| 5CX-5 Magnetic Separator | Power: 1.5 kW Weight: 800 kg Force: ≥19000 Gs Dimension: 2050×1850×3250 mm |

| 5XFC-10D Grader Machine | Power: 2.25 kW Weight: 1000 kg Dimension: 3400×1800×2000 mm |

| 52 bags Dust Collector (for 5XZC-10DX) | – |

| Dust Collector System (for destoner & gravity separator) | Including dust cover, air pipe, air fan and motor, 52 bags dust collector |

| Storage Bin with Bucket Elevator | 5 CBM |

Want to Process Your Cocoa Beans Further?

If you want to turn cleaned, high-quality cocoa beans into cocoa products, Taizy offers complete deep-processing solutions. Every step is carefully designed to ensure high quality and high yield, while being easy to operate and maintain, helping you upgrade your production.

Option 1: Cocoa Paste Production Line

This line grinds clean cocoa beans into cocoa liquor (paste), suitable for chocolate, candy, beverages, and more. The line is designed for even grinding and precise temperature control, ensuring smooth texture and rich flavor. Production capacity can be adjusted to meet different processing scales.

Option 2: Cocoa Powder Production Line

This line further processes cocoa liquor into cocoa powder, widely used in baking, beverages, and flavoring. It includes pressing, grinding, sieving, and packaging steps. The powder is uniform, with adjustable fineness, and can be customized to meet customer specifications. The line is highly automated, efficient, easy to operate, and ensures stable, reliable products.

Partnering with Taizy

By choosing Taizy, you receive one-on-one guidance, customized solutions, and full technical support. From machine selection and process design to installation and commissioning, Taizy provides professional services to ensure your cocoa processing project runs smoothly and efficiently. We also offer fast delivery, remote assistance, and long-term after-sales support for worry-free production.