Полностью автоматическая линия очистки фисташек — это система непрерывной обработки, предназначенная для эффективного удаления скорлупы и разделения ядер в оболочках. Включает сортировку, точную очистку и эффективное разделение для автоматической обработки от сырья до готовых ядер. Подходит для первичной обработки и предварительной подготовки фисташек перед дальнейшей переработкой.

Оболочки фисташек тонкие, но прочные, а ядра хрупкие, что требует высокой точности очистки и равномерного питания. Эта линия оптимизирована по структуре под особенности фисташек. Обеспечивает высокий уровень очистки при низком повреждении ядер, гарантируя стабильное качество продукции.

С мощностью 100 кг в час, линия широко используется на фабриках по переработке фисташек, экспортных заводах и цехах предварительной обработки сырья для глубокой переработки орехов.

Применимое сырьеls

- Оболоченные фисташки — основная цель обработки

Советы по обработке:

Для достижения лучших результатов очистки материалы должны быть сухими и чистыми. Избегайте камней, металла и других посторонних предметов. Настраивайте параметры в зависимости от размера и твердости.

Процесс линии очистки фисташек

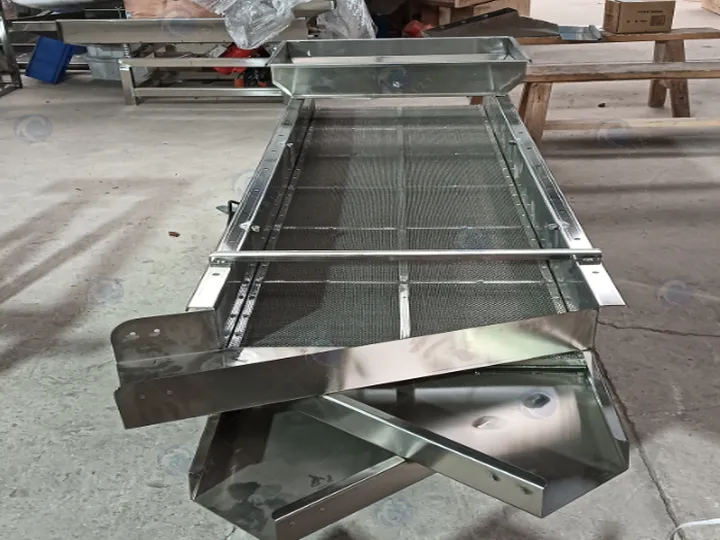

Сортировка фисташек (трехслойный сортировочный экран)

Сырье в скорлупе сначала подается в трехслойный сортировочный экран для классификации по размеру.

Машина оснащена тремя слоями сортировки, что позволяет разделять фисташки на три различных размера. Это обеспечивает равномерную подачу в процессе очистки и эффективно снижает повреждение ядер из-за различий в размере.

- Уровни сортировки: 3 размера

- Размер машины: 2000 × 600 × 1100 мм

- Мощность: 0.4 кВт

Правильная сортировка значительно повышает стабильность очистки и помогает поддерживать более высокий уровень целых ядер.

Очистка фисташек (Машина для очистки фисташек)

После сортировки фисташки подаются на машину для очистки скорлупы.

Машина оснащена мотором с регулируемой скоростью, что позволяет настраивать рабочую скорость в зависимости от размера фисташек и твердости скорлупы, обеспечивая стабильную работу по открытию скорлупы.

- Мощность мотора: 2.6 кВт

- Напряжение: 380 В / 50 Гц

- Производительность: около 120 кг/ч

- Процент открытия скорлупы: ≥95%

- Уровень повреждения ядер: ≤8%

- Материал: нержавеющая сталь

- Размеры машины: 3.2 × 1 × 1.9 м

После очистки смесь ядер и скорлупы передается на этап разделения.

Разделение ядра и скорлупы (воздушный сепаратор / машина для очистки от оболочки)

Смесь очищенных ядер и скорлупы обрабатывается пневматическим сепаратором ядер и скорлупы.

Используя различие плотности между ядрами и скорлупой, машина сочетает воздушный поток и просеивание для эффективного разделения.

- Мощность: 1,1 кВт

- Напряжение: 380 В / 50 Гц

- Общий размер: 0.9 × 0.9 × 1.6 м

- Метод разделения: гравитация воздушный поток

- Эффективность разделения: 90–95%

Отделенные ядра фисташек могут быть отправлены прямо на упаковку или дальнейшую обработку, а пустая скорлупа — отдельно.

Основные преимущества линии очистки фисташек

Разработано для характеристик очистки фисташек

Исходя из тонкой и прочной структуры скорлупы фисташек и их хрупких ядер, линия сочетает трехслойную сортировку с переменной скоростью очистки. Это обеспечивает трещины в фисташках разного размера при оптимальных условиях работы, уменьшая повреждение ядер.

Стабильная производительность для малых и средних предприятий

Линия предназначена для выхода около 100 кг/ч, имеет компактную компоновку и низкое энергопотребление. Подходит для небольших предприятий по переработке фисташек, пилотных линий и начальных инвестиционных проектов.

Высокий процент открытия скорлупы с контролируемым повреждением

При равномерной подаче и регулируемой скорости очистки линия достигает процент открытия скорлупы ≥95%, при этом уровень повреждения ядра не превышает 8%, обеспечивая хороший баланс между эффективностью и качеством продукции.

Эффективное разделение ядра и скорлупы

Воздушный сепаратор ядер и скорлупы использует гравитацию и воздушный поток для разделения, достигая эффективности разделения 90–95%. Ядра и скорлупа выводятся отдельно, что значительно сокращает ручную сортировку.

Материалы пищевого класса для безопасной обработки

Ключевые компоненты, контактирующие с фисташками, изготовлены из нержавеющей стали, соответствующей стандартам гигиены пищевой промышленности. Конструкция устойчива к коррозии, легко очищается и подходит для длительной работы в пищевом производстве.

Простая конфигурация с экономическими вложениями

Линия состоит из сортировочных, очистительных и разделительных блоков, занимает минимальное пространство и требует минимального обслуживания. Обеспечивает экономичное решение для клиентов, ищущих надежную очистку фисташек при умеренной мощности.

Полностью автоматическая линия очистки фисташек мощностью 100 кг/ч

Список машин

| № | Наименование оборудования (на английском) | Количество |

|---|---|---|

| 1 | Трехслойный сортировочный экран для фисташек | 1 единица |

| 2 | Машина очистки фисташек | 1 единица |

| 3 | Воздушный сепаратор ядер и скорлупы | 1 единица |

Технические характеристики машины

| № | Наименование машины | Технические параметры |

|---|---|---|

| 1 | Трехслойный сортировочный экран для фисташек | Размер машины: 2000 × 600 × 1100 мм Мощность: 0.4 кВт Слои экрана: 3 слоя (3 размера) |

| 2 | Машина очистки фисташек | Мотор: мотор с регулируемой скоростью Мощность: 2.6 кВт Напряжение: 380 В / 50 Гц Производительность: около 120 кг/ч Процент открытия скорлупы: ≥95% Уровень повреждения ядер: ≤8% Размер машины: 3.2 × 1 × 1.9 м Размер упаковки: 3.7 × 1.1 × 2 м Материал: нержавеющая сталь Вес: около 260 кг |

| 3 | Воздушный сепаратор ядер и скорлупы | Мощность: 1,1 кВт Напряжение: 380 В / 50 Гц Общий размер: 0.9 × 0.9 × 1.6 м Метод разделения: гравитация воздушный поток Эффективность разделения: 90–95% |

Глобальные применения и признание клиентов

Автоматическая линия очистки фисташек успешно применяется в проектах по переработке орехов в Африке, Центральной Азии, Восточной Европе и других регионах. Клиенты высоко оценивают её стабильность, эффективность обработки и качество продукции.

Если вы ищете эффективное, надежное и масштабируемое решение для очистки фисташек, свяжитесь с нами для получения подробных конфигураций и технической поддержки.