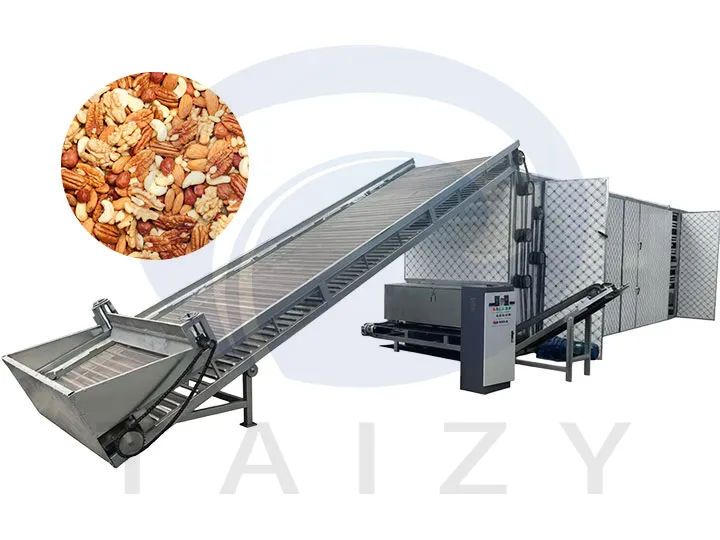

Роторный сушильный шкаф с ленточным конвейером — это относительно распространенное оборудование для сушки, но также оно является непрерывным, крупномасштабным и энергоэффективным оборудованием для сушки. Он может использоваться не только для сушки. Но и для различных культур, овощей, фруктов, китайских трав, продуктов питания и т.д.

Когда необходимо высушить большие объемы орехов, идеально подходит ленточный сушильный шкаф для эффективной и стабильной работы. Он предлагает широкий спектр применений и особенно подходит для листовидных, полосатых и гранулированных материалов с хорошей воздухопроницаемостью, обеспечивая непрерывную и равномерную сушку.

Тайзи ленточные сушильные шкафы доступны в различных ширинах ленты и конфигурациях слоев, с сушильной мощностью от 400 до 14 000 кг в час. Система поддерживает электрический нагрев, нагрев от воздушного источника и горячий воздух. Благодаря полным характеристикам и настраиваемым дизайнам, ленточный сушильный шкаф можно адаптировать под конкретные требования обработки для повышения эффективности сушки и обеспечения стабильного качества продукции.

Why Do Nuts Need Drying?

Drying nuts before commercial processing is a necessary step before roasting. Its main purpose is to control moisture, ensure quality, and improve efficiency. Skipping drying can cause various quality issues. Key reasons:

Even roasting and better texture

- Raw nuts have high moisture (8%-12%). Roasting directly can burn the outside while leaving the inside raw.

- Low-temperature drying removes surface water first, then high-temperature roasting cooks nuts evenly for consistent taste.

Prevent oil leakage and improve appearance

- High-moisture nuts release internal oil quickly during roasting, causing oily, dark, sticky surfaces.

- Drying reduces moisture to 3%-5%, keeping nuts dry, crispy, and evenly colored.

Reduce mold risk and ensure food safety

- High moisture promotes mold and aflatoxin formation.

- Drying lowers moisture below the safe level, stopping mold growth and reducing toxin risk.

Improve roasting efficiency and save energy

- Removing most free water first means roasting only needs to heat the bound water inside.

- This shortens roasting time by 30%-50%, increases output, and lowers energy use.

Stabilize quality and extend shelf life

- Drying ensures uniform low moisture. Roasted nuts stay crisp, resist softening, and oxidize more slowly.

- Shelf life can be extended to 1–2 years.

Applications

- Орехи: Almonds, peanuts (with shell), walnuts, cashews, hazelnuts, and other common nuts.

- Fruits: Dates, papaya slices, hawthorn slices, apple slices, lemon slices, kiwi, mulberries, etc.

- Vegetables: Asparagus, carrots, green beans, lentils, eggplant, red peppers, chili, cucumber slices, mushrooms, shiitake, ginger slices, garlic slices, etc.

- Herbal Materials: Honeysuckle, nasturtium, burdock, ginseng, mulberries, etc.

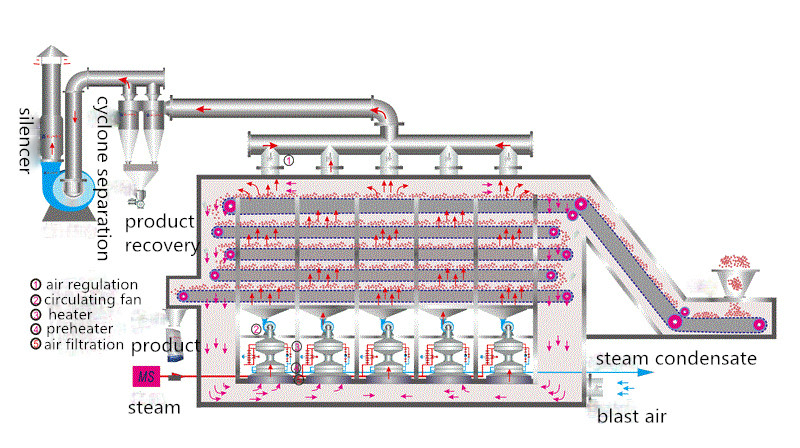

Working Principle of Mesh Belt Dryer

The continuous conveyor dryer dries materials by spreading them on a mesh belt, which moves back and forth inside the dryer via a conveyor-driven mechanism. At the same time, hot air passes through the materials, and moisture is expelled through a dehumidifying fan.

Key Features:

- Side baffles: Prevent material from spilling off the belt.

- Observation & maintenance doors: Allow easy monitoring of drying and routine maintenance.

- Stainless steel construction: The chamber walls and belt are made of stainless steel, improving heat efficiency, preventing contamination, and extending service life.

- Mesh belt design: Standard 3 mm openings prevent small particles from falling while ensuring full air circulation.

- Adjustable size: Drying length can be set from 8 to 20 meters, and belt width ranges from 1.2 to 2 meters.

This design ensures uniform, efficient drying for a wide range of materials while maintaining hygiene and durability.

Core Functions of Continuous Nut Drying Machine

- Continuous Production: Automatic feeding → mesh belt conveying → low-temperature drying → automatic discharge; 24/7 operation, 3–5× higher efficiency than batch machines.

- Precise Temperature Control: Adjustable 40–90°C; low-temperature slow drying preserves original flavor and nutrients without scorching.

- Intelligent Humidity Control: Real-time moisture monitoring with automatic dehumidification and air compensation; prevents dampness, mold, or under-drying; stable moisture content.

- Adjustable Air & Belt Speed: Suitable for different nut types and moisture levels; drying uniformity ≥98%.

- Segmented Temperature & Humidity Control: Preheating, constant-speed drying, and deceleration zones remove free water first, then bound water; prevents surface burning and raw interiors.

- Energy-efficient Hot Air Circulation: Increases thermal efficiency by over 30%; even heating with no dead zones.

- Automatic Material Control & Leak Prevention: Anti-leak mesh belt and variable-frequency feeder ensure uniform material distribution and consistent drying results.

- Food-grade Sanitary Design: 304/316 stainless steel, no dead corners, fully enclosed operation; dust- and odor-free; meets GMP standards.

- Automated Control: PLC touchscreen, one-touch process parameter storage; direct recall for material changes; reduces labor.

- Overload & Over-temperature Protection: Automatic shutdown and alarm for equipment and material safety.

- Compatible with Subsequent Roasting: Discharge temperature controllable (≤40°C); can directly connect to roasting machines for integrated “drying + roasting” production.

Технические параметры

| Параметр | SL-1.2-8 | SL-1.2-10 | SL-1.6-8 | SL-1.6-10 | SL-2-8 | SL-2-10 | SL-2-20 |

|---|---|---|---|---|---|---|---|

| Units | 4 | 5 | 4 | 5 | 4 | 5 | 10 |

| Belt Width (m) | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 |

| Drying Length (m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 |

| Material Thickness (mm) | 10–80 | 10–80 | 10–80 | 10–80 | 10–80 | 10–80 | 10–80 |

| Service Temperature (°C) | 50–140 | 50–140 | 50–140 | 50–140 | 50–140 | 50–140 | 50–140 |

| Steam Pressure (MPa) | 0.2–0.8 | 0.2–0.8 | 0.2–0.8 | 0.2–0.8 | 0.2–0.8 | 0.2–0.8 | 0.2–0.8 |

| Steam Consumption (kg/h) | 120–130 | 150–375 | 150–375 | 170–470 | 180–500 | 225–600 | 450–1200 |

| Drying Time (h) | 0.2–1.2 | 0.25–1.5 | 0.2–1.2 | 0.25–1.5 | 0.2–1.2 | 0.2–1.5 | 0.5–3 |

| Drying Capacity (kg/h) | 60–160 | 82–220 | 75–220 | 95–250 | 100–260 | 120–300 | 240–600 |

| Total Power (kW) | 11.4 | 13.6 | 11.4 | 13.6 | 14.7 | 15.8 | 36.8 |

| Machine Length (m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 |

| Machine Width (m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| Machine Height (m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 |

| Total Weight (kg) | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 |

The models above are our standard options. We can also match a mesh belt drying machine of suitable size according to your specific requirements. In addition, we offer customization services for material, power supply, plug type, and other specifications.

Связанные продукты

In addition to mesh belt dryers, we also offer trolley-type Hot air circulating drying ovens, which are widely welcomed by customers around the world.

Advantages of Mesh Belt Dryer Machine

High-Efficiency Continuous Production

- Auto feeding → Continuous conveyor → Automatic discharge

- 24/7 operation, 3–10× higher capacity than batch or box dryers

- Ideal for large-scale nut processing

Even Heating, Consistent Quality

- Multi-layer mesh belt + hot air circulation (through/side-blown)

- Slow belt movement ensures uniform drying for every layer and every nut

- Finished product pass rate ≥98%

. Low-Temperature Drying, Nutrient Preservation

- Precise control: 40–90°C

- Gentle drying prevents burning, color change, and nutrient loss

- Retains the original flavor and quality of nuts

Energy Saving & High Efficiency

- Hot air recirculation reuses heat, efficiency +30%

- Enclosed design minimizes heat loss, saving electricity/gas costs

Automated Control, Labor Saving

- PLC touchscreen + variable frequency control (temperature, airflow, belt speed)

- One-touch process setup and start/stop

- Reduces labor and prevents operator errors

Hygienic & Food-Safe

- All material-contact parts made of stainless steel, fully compliant with food safety standards

- Enclosed operation, dust- and odor-free, GMP-compliant

Nut Processing Special Advantages

1. Perfect “Drying + Roasting” Integration

- Can work alone or connect directly to the conveyor roaster

- Seamless low-temperature drying → high-temperature roasting

- Increases production efficiency by 50%, reduces material loss

2. Precise Moisture Control, Prevents Mold & Re-Moistening

- Intelligent dehumidification system removes high-humidity air in real time

- Dried nuts reach a stable 3–5% moisture

- Ensures optimal conditions for roasting and extended shelf life

3. Protects Oils, Maintains Appearance

- Gentle drying prevents oil leakage and stickiness

- Nuts remain dry and crispy; uniform color after roasting

- Reduces rancidity and preserves visual appeal

4. Multi-Layer Design, Maximized Space Use

- 3–10 layers optional for vertical drying

- 3–10× drying area in the same floor space

- Saves factory space and cost

5. Versatile, Suitable for Multiple Nut Types

- Adjust temperature, airflow, and belt speed for almonds, cashews, walnuts, peanuts, etc.

- One machine handles all types of nuts

Почему выбирают Taizy?

- High Quality Manufacturing

All machines are made of food-grade stainless steel, ensuring durability, stability, and long service life. - Certified & Reliable

Products are certified with ISO 9001 и CE, and also approved by TÜV и SGS, guaranteeing quality, safety, and compliance with international standards. - 1-Year Warranty

A full 12-month warranty is provided for worry-free operation. - Complete After-Sales Service

- Detailed installation manuals included

- Online remote technical guidance is available

- On-site installation and commissioning by engineers when required

- Professional End-to-End Support

From delivery and installation to operation and maintenance, Taizy provides continuous technical support to ensure smooth and efficient production.