Isang semi-automatic peanut butter production line na nakatindig sa pagitan ng isang ganap na awtomatiko na sistema at manual na proseso. Naimo-mekanisa nito ang lahat ng pangunahing yugto—tulad ng pag-rotor ng mais, pag-peel, paggiling, at paghalo—pinapalitan ang mga labor-intensive na hakbang ng mahusay na makinarya. Kung saan tutulong lamang ang mga operator sa ilang bahagi ng daloy ng trabaho, tumataas ang kahusayan ng produksyon nang hindi kinakailangang mataas na puhunan ng isang ganap na awtomatiko na linya, na maaaring umabot ng sampu-sampong libong dolyar.

Taizy အားနားမဲ့အလယ်အလတ်ပမာဏပဲနတ်ပျားထုတ်လုပ်မှုလိုင်းသည် 50–100 kg/h အတွက်ဒီဇိုင်းထုတ်ထားပြီး၊ သေးငယ်နှင့်အလတ်စားပဲနတ်ပျားထုတ်လုပ်သူများအတွက်အကောင်းဆုံးဖြစ်သည်။ ၎င်းသည်မြင့်မားသောလျှောလျှောကျ, လွယ်ကူသောစီမံခန့်ခွဲမှုနှင့်ရိုးရှင်းသောပြုပြင်ထိန်းသိမ်းမှုကိုပေးပြီးနေ့စဉ်ထုတ်လုပ်မှုလိုအပ်ချက်များကိုဖြည့်ဆည်းပေးနိုင်သည်။

Hanggang ngayon, nagbigay na kami ng peanut butter processing solutions sa mahigit 40 bansa at rehiyon. Ang aming kagamitan ay na-export na sa Italy, Canada, Democratic Republic of the Congo, South Africa, at marami pang ibang bansa, na nag-ulat ng malawak na positibong feedback mula sa mga customer.

အဆင့်တစ်ခုပြုလုပ်သော ပဲဆီထုတ်လုပ်ရေးလိုင်း၏ အားသာချက်များ

Mas mababang puhunan, mas mabilis na kita

အပြည့်အဝအလိုအလျောက်လိုင်းများနှင့်နှိုင်းယှဉ်ပါက၊ ရင်းနှီးမြှုပ်နှံမှု၏ 30%–50% ကိုချွေတာနိုင်သည်။ ပြုပြင်ထိန်းသိမ်းရလွယ်ကူပြီး လုပ်ငန်းများအတွက်သင့်တော်သည်။

လျှောလျောကျထုတ်လုပ်နိုင်မှု (50–100 kg/h)

50–100 kg/h ထုတ်လုပ်မှုကိုထောက်ပံ့ပေးနိုင်သည်။ မြင့်မားသောအဆင့်မြှင့်တင်နိုင်ပြီး၊ အနာဂတ်တွင်အပြည့်အဝအလိုအလျောက်ပဲနတ်ပျားထုတ်လုပ်မှုလိုင်းသို့အဆင့်မြှင့်တင်နိုင်သည်။

Madaling operasyon, mas kaunting labor

Ang mga pangunahing proseso ay mekanisado, nababawasan ang manwal na gawain. Kakaunting mga manggagawa ang kailangan para patakbuhin ang buong linya.

Stable product quality

Automatic grinding, even mixing, and precise filling ensure consistent taste and smooth texture.

Compact footprint, angkop sa iba't ibang lugar

Compact layout na angkop sa maliliit na pabrika, mga startup na workshop, o mga rural na proyekto sa pagpoproseso ng pagkain.

Modular na disenyo para sa madaling maintenance at upgrade

Ang semi-automatic peanut butter production line ay may modular na estruktura. Maaaring gumana nang hiwalay o magkakasama ang roasting, peeling, grinding, at filling machines. Maaaring magdagdag o palitan ang mga makina ayon sa mga order, binabawasan ang mga gastos sa pagpapanatili at pinahihintulutan ang hinaharap na ekspansyon o automation upgrades.

Pangunahing daloy ng proseso ng peanut butter production line

အဆင့်တစ်ခုပြုလုပ်သော ပဲဆီထုတ်လုပ်ရေးလိုင်းသည် အောက်ပါ စက်ခုနှစ်ခုမှ ဖွဲ့စည်းထားသည်။

ငှက်ဥကြက်သွန်နီဖွင့်စက်

ပဲနတ်ပျားအကြော်စက်ကိုပဲနတ်ပျား၏အပြင်အထပ်အကြော်ကိုဖယ်ရှားရန်အသုံးပြုသည်။ ပဲနတ်ပျားကိုစက်ထဲထည့်ပြီးပါက၊ လျှပ်စစ်အားကိုဖွင့်လိုက်သည်နှင့်အတူ ပဲနတ်ပျားအကြော်များကိုအမြန်ဖွင့်မည်။ ထို့နောက်အကြော်နှင့်ပဲနတ်ပျားအကြွေစေ့များကိုခွဲခြားပြီးအမျိုးမျိုးသောထွက်ပေါက်များမှထုတ်ပေးမည်။ ထို့အပြင် ပဲနတ်ပျားအကြော်စက်သည်အလုပ်လုပ်မှုမြန်နှုန်းမြင့်မားပြီး သစ်ပင်များကိုမပျက်စီးစေပါ။

Mga Teknikal na parameter

| Model | ထုတ်လုပ်မှု | ဓာတ်အား | အရွယ်အစား | အလေးချိန် | သီးခွာခြင်းနှုန်း |

| TZ-200 | ၂၀၀ကီလိုဂရမ်/နာရီ | gasoline engine 170F, motor/diesel engine 6 horsepower | ၆၅၀*၅၆၀*၁၀၀၀မီလီမီတာ | ၆၅ကီလိုဂရမ် | ≥၉၈% |

| TZ-၄၀၀ | ၃၀၀-၄၀၀ကီလိုဂရမ်/နာရီ | gasoline engine 170F, ဒီဇယ်အင်ဂျင် ၆-၈ ဟိုက်ပေါ့ဆာ | ၁၂၀၀*၇၀၀*၁၄၀၀မီလီမီတာ | ၁၃၀ကီလိုဂရမ် | ≥၉၈% |

| TZ-800 | 600-800 ကီလိုဂရမ်/နာရီ | gasoline engine 170F, diesel engine 8-10 horsepower | 1400*900*1600mm | 160KG | ≥၉၈% |

မြေပဲရောစက်

Ang roasting machine ay isang mahalagang makina sa peanut butter production line. Mayroong maraming heating methods, kabilang ang electric heating, gas heating, at iba pa. Ang prinsipyo ng operasyon ng peanut roaster ay pangunahing upang makamit ang pantay na pag-init ng mga materyales sa pamamagitan ng pag-ikot ng drum. Maaaring itakda din ng operator ang temperatura ng pag-init nang maaga. Pagkatapos ng preheating, ang mani na walang balat ay ilalagay sa silindro para sa roasting.

Mga Teknikal na parameter

| မော်ဒယ် | TZ-MHK-1 | TZ-MHK-2 | TZ-MHK-3 | TZ-MHK-4 | TZ-MHK-5 |

| လွှမ်းမိုးမှု အင်အား | 1.1KW | ၂.၂KW | 3.3KW | 4.4KW | 5.5KW |

| အပူပေးမှု အင်အား | 22KW | 35KW | 45KW | 60KW | 75KW |

| Heating Gas (Kg) | 2-3 | 3-6 | 6-9 | 9-12 | 12-15 |

| ဖျော်ဖြေရန် အထွေထွေ | 80-120KG/H | 180-250KG/H | 280-350KG/H | 380-450KG/H | 500-650KG/H |

| အရွယ်အစား (မီလီမီတာ) | 3000*1200*1700 | 3000*2200*1700 | 3000*3300*1700 | 3000*4400*1700 | 3000*5500*1700 |

ပဲသီးဖျက်စက်

ကျွန်ုပ်တို့သည် ပဲလွှာဖျက်ခြင်းလုပ်ငန်းစဉ်ကို အသုံးပြု၍ ပဲထုတ်ထားသောမုန်လာဥာဏ်ကို ပြုလုပ်သည်။ ပဲလွှာဖျက်စက်သည် ပဲ၏ အနီရောင် အပင်လွှာကို ဖယ်ရှားရန် အင်္ဂါရပ်စွမ်းအားဖြစ်သော အဆီလိပ်ရောလားကို အသုံးပြုသည်။ ၎င်း၏ လွှာဖျက်နှုန်းသည် ၉၈% အထက် ရောက်ရှိနိုင်သည်။

Mga Teknikal na parameter

| မော်ဒယ် | ထုတ်လုပ်မှု | မော်တော်အား | ဖန်ခွင့် | ဗို့အား | Hz | သစ်သားကို ဖျက်ဆီးခြင်း အထွတ်အထိပ် | half-kernel rate | အရွယ်အစား |

| TZ-1 | 200-300kg/h | ၀.၅၅ကီလိုဝတ် | 0.37kw | 380V/220V | ၅၀ဟ်ဇ် | >98% | ≤5% | 1100*400*1100mm |

| TZ-2 | ၄၀၀-၅၀၀ကီလိုဂရမ်/နာရီ | ၀.၅၅ကီလိုဝတ်*၂ | 0.37kw | 380V/220V | ၅၀ဟ်ဇ် | >98% | ≤5% | ၁၁၀၀*၇၀၀*၁၁၀၀မီလီမီတာ |

| TZ-၃ | 600-800 ကီလိုဂရမ်/နာရီ | ၀.၅၅ကီလိုဝတ်*၃ | 0.37kw | 380V/220V | ၅၀ဟ်ဇ် | >98% | ≤5% | ၁၁၀၀*၁၀၀၀*၁၁၀၀မီလီမီတာ |

| TZ-4 | ၈၀၀-၁၀၀၀ကီလိုဂရမ်/နာရီ | 0.55kw*4 | 0.37kw | 380V/220V | ၅၀ဟ်ဇ် | >98% | ≤5% | 1100*1400*1100mm |

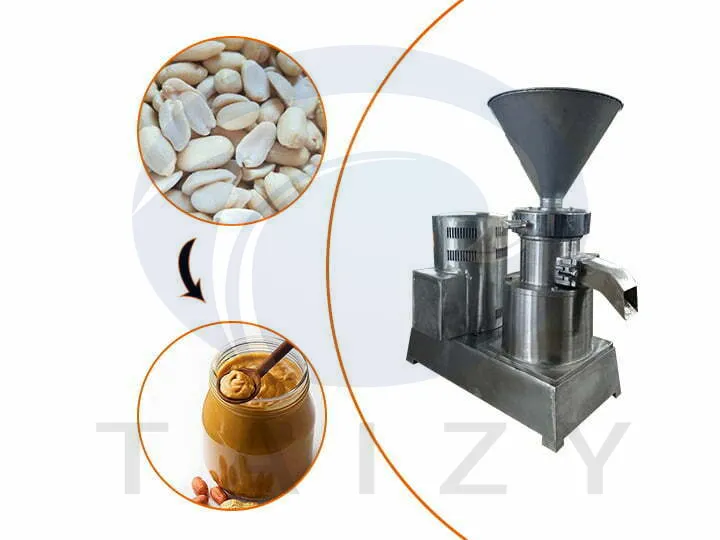

ငါးခြောက်ချိုသုတ်စက်

ပုံမှန်အခြေအနေများအောက်တွင်၊ မုန်လာဥသုပ်ကို ဂရိုင်းဒ်မောင်းစက်ဖြင့် ဂရိုင်းဒ်လုပ်သောအခါ၊ အရည်အသွေးသည် 100-150 မက်ရှ် ဖြစ်သည်။ သို့သော် အမှန်တကယ်လုပ်ဆောင်မှုအခြေအနေများအရ ပြောင်းလဲနိုင်ပါသည်။ လုပ်ဆောင်မှုအတွက် အတွေ့အကြုံများအရ၊ မုန်လာဥသုပ်ကို 80-85℃ တွင် ဂရိုင်းဒ်လုပ်ပါက အရသာအကောင်းဆုံးရရှိသည်။

| မော်ဒယ် | JM-50 | JM-85 | JM-130 |

| ပစ္စည်းအလုပ်လုပ်ခြင်း၏ အနိမ့်ဆုံးအရွယ်အစား (um) | 20-70 | 20-70 | 20-70 |

| မူလမော်တာစွမ်းအား kW | 1.5 | 5.5 | 7.5 |

| ထုတ်လုပ်မှု t/h | 0.2-0.8 | 0.2-2 | 0.2-3 |

| မလိုအပ်သောအကြိမ်ရေ r/min | 3000±100 | 3000±100 | 3000±100 |

| Outline dimensions of pipeline discharge in cm | 79*30*70 | 105*40*100 | 115*45*108 |

| Laki ng gilid ng square outlet sa cm | 60*30*62 | 85*40*90 | 96*45*95 |

| ဟော့ပပ် အမြင့် စင်တီမီတာ | 14 | 25 | 30 |

| အလေးချိန် ကီလိုဂရမ် | 60 | 180 | 240 |

| ရေ အအေးစက်စနစ် | အအေးစက်စနစ်ဖြင့် ကောင်းကင်ဖြစ်စေသည် | အအေးစက်စနစ်ဖြင့် ကောင်းကင်ဖြစ်စေသည် | အအေးစက်စနစ်ဖြင့် ကောင်းကင်ဖြစ်စေသည် |

ပဲသုတ်ဆီ လှည့်လည်မှု တိုင်

Ang pangunahing layunin ng garapon ay maiwasan ang pag-solidify ng peanut butter. Ngunit maaari rin itong gamitin bilang proseso ng pampalasa. Pagkatapos ang peanut butter ay mabuo ng milling machine at ilipat sa agitation tank, dinadagdagan ng asin o asukal para sa lasa ng peanut butter. Maaaring magdagdag ng naaangkop na dami ng stabiliser upang pahabain ang shelf life ng peanut butter.

ဗက်ကျွန်း ဖျက်သိမ်းမှု တိုင်

Pagkatapos ng naunang hakbang ng paghahalo, ang peanut butter ay bubuo ng ilang mga bula, kaya kailangan ng degassing tank. Kung masyadong marami ang bula, hindi ito magiging maganda para sa susunod na imbakan ng peanut butter.

ငှက်ပျောသီးဆီဖြည့်စက်

Kapag ang peanut butter ay naihanda na, handa na itong i-pack. Karaniwang inaayos ang pag-pack ng peanut butter ng filling machine. Ang filling machine ay gumagamit ng pneumatic na prinsipyo upang maisagawa ang proseso ng pagpuno; ang dami ng pagpuno ay maaaring maayos. At ang pagsukat ng pagpuno ay karaniwang nasa pagitan ng ±1-2%.

Application Scenarios and Industry Uses

Ang semi-automatic peanut butter production line ay angkop para sa:

- Maliliit at katamtamang laki ng mga pasilidad ng Pagkaing processing

- Peanut farming cooperatives or joint processing workshops

- Mga trading companies na gumagawa ng sarili nilang processing rooms

- Mga proyektong agrikultural na by-product processing

- Low-cost startup factories in overseas markets (Africa, Southeast Asia, South America, etc.)

- Mga negosyo na nagnanais magsimula ng maliit at unti-unting mag-scale up

Kung gumagawa ng purong peanut butter, spicy peanut butter, chocolate peanut butter, o flavored peanut butter, ang semi-automatic line ay nagsisiguro ng matatag at pare-parehong kalidad ng output.

Regular na pagpapanatili at mga paalala ng semi-automatic peanut butter production line

1. Pang-araw-araw na Paglilinis

- Ang mga parte na contact sa pagkain tulad ng grinders, mixing tanks, at filling machines ay dapat linisin araw-araw upang maiwasan ang bacterial growth o flavor contamination.

- Gumamit ng mainit na tubig at food-grade detergents; iwasan ang mapanirang kemikal.

- Pagkatapos paglilinis ng grinder, i-drain ng maigi o patakbuhin ng sandaling walang load upang alisin ang tubig at maiwasan ang kalawang.

2. Regular Inspection of Wear Parts

- Check wear parts such as grinding plates, belts, screens, and seals regularly.

- Kung mapapansin ang hindi pantay na paggiling, mababang output, o pagtaas ng ingay, palitan ang grinding plates o suriin ang bearings.

- Suriin ang seals at valves ng filler upang maiwasan ang leakage o hindi matatag na pagpuno.

3. Lubrication of Mechanical Components

- Lubricate bearings, chains, and motor couplings according to the manufacturer’s recommendations.

- Huwag gumamit ng hindi-standard na lubricants upang iwasan ang kontaminasyon ng produkto o pinsala sa kagamitan.

- Monitor ang temperatura ng motor; ihinto ang makina agad kung sobra ang init.

4. Electrical System Safety

- Bago magsimula ang bawat araw, tiyaking tuyo ang control cabinet at wiring.

- Suriin kung maayos ang emergency stop button.

- Huwag buksan ang electrical cabinet habang ang makina ay tumatakbo.

5. အပူချိန်စက်များအတွက်မှတ်ချက်များ(အပူချိန်အပူပေးစက်များနှင့်လျှပ်စစ်အပူချိန်စက်များအတွက်)

- Suriin ang sistema ng pagkontrol ng temperatura upang maiwasan ang hindi pantay na pag-init o sobrang init.

- Linisin ang alikabok at langis sa paligid ng heating area upang mabawasan ang panganib ng sunog.

- Para sa gas heating, regular na inspeksyunin ang gas lines, valves, at mga tagas.

6. Panatilihing malinis ang Production Area

- Panatilihing malinis ang sahig mula sa langis at balat ng mani upang maiwasan ang pagdulas at kontaminasyon.

- Itabi ang mga hilaw na mani sa tuyong lugar na may ventilasyon upang maiwasan ang amag o pagkakaroon ng kahalumigmigan.

- Ihiwalay ang mga gamit sa paglilinis mula sa mga hilaw na materyales upang maiwasan ang kontaminasyon ng cross.

100 kg/h ပဲနတ်ပျားထုတ်လုပ်မှုလိုင်းဖွဲ့စည်းမှုစာရင်း

| စက်ပစ္စည်းအမည် | အသွားအလာအချက်အလက်များ |

|---|---|

| ရိုးစွန်းစက် | မော်ဒယ်: TZR-100 ထုတ်လုပ်မှု: 100 kg/h မော်တာစွမ်းအား: 1.1 kW လျှပ်စစ်အပူချိန်စွမ်းအား: 22.5 kW အပူချိန်အပတ်: 0–300 °C ထိန်းချုပ်မှု: အလိုအလျောက်အပူချိန်ထိန်းချုပ်မှု Material: Stainless steel အတိုင်းအတာ: 2900 × 1400 × 1650 mm |

| ပဲသီးဖျက်စက် | စွမ်းရည်: 100–200 kg/h စွမ်းအား: 0.75 kW အတိုင်းအတာ: 1100 × 450 × 1100 mm |

| ပဲနတ်ပျားအကြော်စက် (Butter Machine) | မော်ဒယ်: TZ-110 စွမ်းရည်: 80–100 kg/h ဗို့: 380 V, 50 Hz စွမ်းအား: 7.5 kW အကြမ်းအနည်းဆုံးအရည်အချင်း: 2–100 μm အတိုင်းအတာ: 700 × 430 × 1000 mm |

| ထိုးထွင်းစက် | အရည်ပမာဏ: 100–1000 ml စွမ်းရည်: 400–500 ပုလင်း/နာရီ ဖွဲ့စည်းမှု: နှစ်ခေါက်ဖြည့်စွမ်းမှု |

| လေထု ဖိအားတင်စက် | ဗို့: 380 V, 50 Hz, 3-phase စွမ်းအား: 3 kW |

| အဖုံးစက် | စွမ်းအား: 0.37 kW စွမ်းရည်: 20 ပုလင်း/မိနစ် သင့်တော်သောဘူးအမြင့်: 160–300 mm အတိုင်းအတာ: 630 × 240 × 940 mm |

| အလယ်အလတ်အလိုအလျောက်လက်မှတ်စက် | စွမ်းအား: 100 W ဘူးအကျယ်: 15–120 mm လက်မှတ်စက်အမြန်နှုန်း: 20–40 ဘူး/မိနစ် လက်မှတ်အရွယ်အစား: W26×L25 – W150×L300 mm လက်မှတ်လှုပ်ရှားမှုအတွင်းအကျယ်: 75 mm အများဆုံးလက်မှတ်လှုပ်ရှားမှုအပြင်အလွှာအကျယ်: 275 mm စက်အရွယ်အစား: 650 × 345 × 450 mm |

မှတ်ချက်။ အထက်ပါဖွဲ့စည်းပုံသည်အကြံပြုချက်အတွက်သာဖြစ်သည်။ နောက်ဆုံးစက်ရွေးချယ်မှုနှင့်အကြံပြုချက်များကိုသင်၏အမှန်တကယ်ထုတ်လုပ်မှုလိုအပ်ချက်များအပေါ်အခြေခံ၍ဆုံးဖြတ်ရမည်။

ဘာကြောင့် Taizy ၏အလယ်အလတ်ပဲနတ်ပျားထုတ်လုပ်မှုလိုင်းစက်ကိုရွေးချယ်ရမည်လဲ?

Taizy (Shuliy ၏အခွင့်အလမ်းအစားအစာလုပ်ငန်းစက်ရုံ) သည်အစားအစာလုပ်ငန်းစက်ပစ္စည်းလုပ်ငန်းတွင်နှစ်ပေါင်းများစွာပါဝင်ပြီး၊ ပဲနတ်ပျားထုတ်လုပ်မှုလိုင်းများတွင်အတွေ့အကြုံနှင့်ဖောက်သည်အမှုများစွာရှိသည်။ ကျွန်ုပ်တို့၏အကျိုးအမြတ်များမှာ:

- 20 taong karanasan sa R&D at paggawa ng peanut butter equipment

- Malin na dinin durables na makina na idinisen para sa mahabang tuloy-tuloy na operasyon

- Mga pangunahing bahagi na gawa sa stainless-steel, malinis at hindi kinakalawang

- Adjustable grinding fineness to match different taste requirements

- Fully customizable line: output, layout, at heating method ay maaaring i-tailor

- Certified equipment (CE, ISO9001) for smooth export

- 1-year warranty and lifetime technical support

အကြမ်းအနေနဲ့နည်းပညာဖြေရှင်းချက်များဖြင့် Taizy သည်အာဖရိက, ထိုင်း, မလေးရှား, နိုင်ဂျီးရီးယား, အော်စတြေးလျနှင့်အလယ်အလတ်အရှေ့အပါအဝင်နိုင်ငံများသို့ပဲနတ်ပျားထုတ်လုပ်မှုလိုင်းများကိုအောင်မြင်စွာပေးအပ်ခဲ့သည်။