خط إنتاج الكاجو مصنع الكاجو مصمم بشكل رئيسي لمعالجة الكاجو غير المقشر إلى نواة مقشرة وتعبئة فراغ كاملة. يشمل الخط الكامل التصنيف، الطهي، التجفيف، التقشير، الفرز، التجفيف الثانوي، التقشير، تصنيف النواة، التحميص، والتعبئة بالفراغ. مع معدل تقشير يزيد عن 98%، فهو مناسب جدًا لمصانع الكاجو بجميع الأحجام.

خط إنتاج نواة الكاجو هذا بسعة 100–800 كجم/ساعة. وفقًا لمتطلبات الإنتاج الخاصة بك، يمكنك اختيار خط معالجة كاجو تلقائي بالكامل أو خط معالجة نصف تلقائي. لا تتردد في الاتصال بنا لمزيد من التفاصيل والاستشارة المهنية.

تدفق عملية خط إنتاج الكاجو

This cashew production line is a complete technological process, which is the preliminary comprehensive processing of cashew after picking. The whole production line adopts semi-automatic operation, compared with the traditional manual processing, the efficiency will be higher, at the same time cashew damage rate will be greatly reduced.

تتطلب تكنولوجيا المعالجة لخط إنتاج جوز الكاجو الآلات التالية:

آلة تصنيف جوز الكاجو

First of all, the initial grading of cashews is to facilitate the subsequent opening of the shell. Because the size of cashews varies, the shelling machine uses the distance between the blades to open the shell. So before opening the shell need to ensure that the size of the cashews is uniform.

The size of cashew nuts is generally divided into 16, 18, 20, 22, and 24mm. The grading machine realises the grading processing of cashew nuts through screens with different pore diameters. Customers can choose the number of grades that should be divided according to actual requirements.

آلة طهي الكاجو

يتم وضع الكاجو المصنف في صندوق الطهي. وفقًا لحجم الكاجو، يختلف وقت الطهي. وقت طهي الكاجو ذو الأحجام الصغيرة أطول، والعكس صحيح.

The main purpose of cooking is to use the principle of heat expansion and cold contraction. So as to separate the shell from the cashew peel and reduce the damage to the cashew nut when the shell opens.

ملاحظة: بعد طهي الكاجو، يجب وضعه في مكان جيد التهوية لمدة 2-3 أيام.

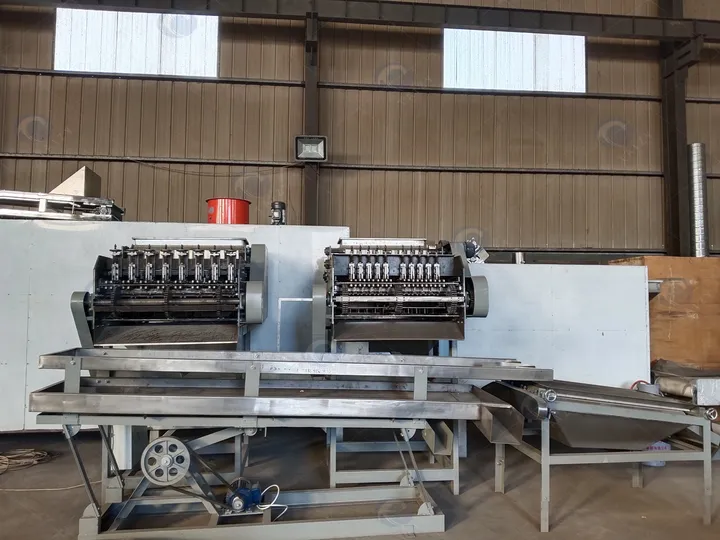

آلة تقشير قشرة الكاجو وفاصل النواة

The shelling machine is divided into the semi-automatic type and automatic type. With a high rate of shellers, the characteristics of small damage to nuts, which is the automatic type of cashew sheller, are the first choice of most customers. The operation principle of these shellers is also very simple.

After the cashews are sent into the feed mouth, the roller will initially clean the cashews and remove the impurities, such as stones mixed into them. Then the cashew nuts will be evenly placed in the shell opening mould and transported to the shell opening device. After the action of the pushing device, the cashew nuts will be cut by the blade, and the cashew nuts will be opened.

After opening, the cashew shell has not been completely separated from the nuts, so it is necessary to use the shell separator to separate the shell and nuts completely.

ماكينة تجفيف الكاجو

The cashew drying machine is used to remove excess moisture from cashews after cooking or shelling, ensuring stable quality and easier peeling.

It features uniform hot-air circulation for even drying, stable operation, and adjustable temperature and time.

This machine helps improve kernel integrity, reduce breakage, and is suitable for small, medium, and large cashew processing lines.

آلة تقشير نواة الكاجو

آلة تقشير نواة الكاجو تزيل الجلد الرقيق من النوى بكفاءة مع الحفاظ على سلامتها. لديها معدل تقشير عالي، تقلل من الكسر، وتناسب خطوط معالجة الكاجو الصغيرة والمتوسطة والكبيرة.

آلة تصنيف نواة الكاجو

آلة تصنيف نواة الكاجو تستخدم لفرز نوى الكاجو المقشرة حسب الحجم والجودة. تضمن تصنيفًا موحدًا، وتحسن كفاءة المعالجة، وتساعد على الحفاظ على جودة المنتج المستمرة. مناسبة لخطوط معالجة الكاجو الصغيرة والمتوسطة والكبيرة.

آلة تعبئة نواة الكاجو بالفراغ

آلة تعبئة نواة الكاجو بالفراغ تستخدم لتفريغ الهواء من عبوات نواة الكاجو المقشرة، مما يطيل مدة الصلاحية ويحميها من الرطوبة والأكسدة. تحافظ على نضارة وسلامة النواة، سهلة التشغيل، وسرعة تعبئة عالية، مناسبة لمصانع الكاجو الصغيرة والمتوسطة والكبيرة.

ميزات ومزايا خط إنتاج الكاجو

معالجة عالية الكفاءة

- الخط لديه سعة قابلة للتعديل من 100–800كجم/ساعة، مناسب للمصانع الصغيرة إلى الكبيرة.

- آلة التقشير التلقائية بالكامل لها معدل تقشير 90–95% مع معدل كسر أقل من 5–10%.

تغطية كاملة للعملية

يشمل التصنيف، والتبخير، والتجفيف، والتقشير، والفرز، والتجفيف الثانوي، والتقشير، وتصنيف النواة، والتحميص، والتعبئة بالفراغ، وإتمام جميع العمليات في خط واحد.

مواد عالية الجودة وهيكل مستقر

الأجزاء التي تتلامس مع النواة مصنوعة من الفولاذ المقاوم للصدأ 304، بينما الإطار ومكونات القيادة فهي من الصلب الكربوني، لضمان المتانة والموثوقية.

سلامة النواة العالية

معدل التقشير ومعدل النواة الكاملة يتجاوز 90%، مما ينتج نوى موحدة وسليمة مع تصنيف دقيق.

سهولة التشغيل وكفاءة الطاقة

- معظم الآلات مزودة بزر تحكم أو محركات بسرعة متغيرة لسهولة التشغيل.

- التسخين الكهربائي في فرن البخار والجفاف يوفر كفاءة عالية، والتعبئة بالفراغ تمد عمر النواة.

الأتمتة والمرونة

- الخط مؤتمت بشكل كبير، يقلل من متطلبات العمالة ويحسن الاتساق.

- يمكن تعديل سعة العملية وإعداداتها لتلبية احتياجات المصنع المختلفة.

خط معالجة الكاجو بقدرة 200كجم/ساعة – قائمة الآلات

| المعدات | المواصفات الرئيسية | الكمية |

|---|---|---|

| آلة تصنيف الكاجو | الحجم: 3600×900×1600مم الجهد: 380فولت، 50هرتز، ثلاث مراحل الطاقة: 1.1ك.و السعة: 400–500كجم/ساعة الوزن: 450كجم | 1 |

| فرن البخار (24 رف، كهربائي) | الحجم: 1500×600×1550مم الجهد: 380فولت، 50هرتز، ثلاث مراحل الطاقة: 18ك.و السعة: 200كجم/ساعة الوزن: 150كجم صواني: 24 المادة: stainless steel | 1 |

| آلة تقشير الكاجو (تلقائية بالكامل YK-8) | يعالج 8 مكسرات في الدورة الحجم: 1450×1330×1550مم الوزن: 480كجم السعة: 200–260كجم/ساعة التحكم: زر المحرك: 1.5ك.و الجهد: 380فولت، 50هرتز، ثلاث مراحل معدل فتح القشرة: 90–95% معدل عدم الفتح: 3% معدل الكسر: <5–10% | 1 |

| آلة فرز القشرة والنواة | الحجم: 2500×700×600مم الطاقة: 0.75ك.و الجهد: 380فولت، 50هرتز، ثلاث مراحل السعة: 500كجم/ساعة الوزن: 230كجم المادة: الصلب الكربوني | 1 |

| آلة التجفيف (60 رف، كهربائية) | الحجم: 2200×1800×2300مم حجم العربة: 650×450×1700مم حجم الصينية: 600×400مم الطاقة الحرارية: 22ك.و الجهد: 380فولت، 50هرتز، ثلاث مراحل طاقة المروحة: 4×0.55ك.و السعة: 400كجم/دفعة حجم الصينية: 1.5–2كجم الوزن: 900كجم المادة: صواني وعربات من الفولاذ المقاوم للصدأ، إطار ومحرك من الصلب الكربوني الطاقة: 0.2ك.و | 1 |

| آلة تقشير نواة الكاجو | الجهد: 380فولت، 50هرتز، ثلاث مراحل معدل التقشير: >90% معدل النواة الكاملة: >90% السعة: 200كجم/ساعة/مجموعة الحجم: 650×650×1300مم المادة: الفولاذ المقاوم للصدأ 304 الطاقة: 7.5ك.و | 1 |

| المكبس الهوائي | الجهد: 380فولت، 50هرتز، ثلاث مراحل الحجم: 3000×900×1300مم | 1 |

| آلة تصنيف نواة الكاجو | الوزن: 300كجم الطاقة: 0.75ك.و الجهد: 380فولت، 50هرتز، ثلاث مراحل المادة: الفولاذ المقاوم للصدأ (أجزاء القيادة والإطار: الصلب الكربوني) خبرة غنية | 1 |

لماذا تختار تايزي؟

- : سنوات من البحث والتطوير والتصنيع في معدات معالجة المكسرات؛ تكنولوجيا ناضجة وموثوقة.كفاءة عالية

- : سعة خط إنتاج الكاجو100–800كجم/ساعة , مناسب للمصانع الصغيرة إلى الكبيرة.سلامة النواة العالية

- : معدل التقشير والنواة الكاملة فوق90–98% , مع انخفاض معدل الكسر.تغطية كاملة للعملية

- : من التصنيف، الطهي، التجفيف، التقشير، الفرز، التحميص، والتعبئة بالفراغ—إكمال عملية خط واحد.مواد عالية الجودة

- : أجزاء الاتصال بالنواة مصنوعة من, إطار ومكونات القيادة 304 الفولاذ المقاوم للصدأالفولاذ الكربوني متين وآمن.مؤتمت وسهل التشغيل

- : معظم الآلات لديهازر تحكم أو محركات بسرعة متغيرة , مما يسهل التشغيل ويحسن الإنتاجية.كفاءة الطاقة وصديقة للبيئة

- : الأفران البخارية والأجهزة التجفيفية ذات التسخين الكهربائي تضمن كفاءة حرارية عالية؛ التعبئة بالفراغ تمد عمر الصلاحية.الضمان والشهادات

- : جميع المعدات تأتي مع ضمان الجودة وتحملCE، ISO9001، TUV، SGS شهادات السلامة والموثوقية. الدعم المهني

- : يوفر تخصيص كامل للخط، وإرشادات التركيب، وخدمة ما بعد البيع لضمان سير الإنتاج بسلاسة.كاجو غير مقشر