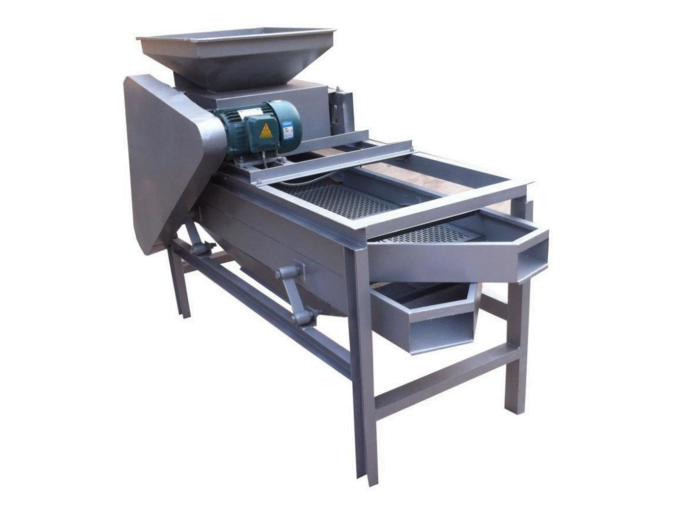

The shell and kernel separation machine is a device for separating nuts from nuts after they are shelled. Its application range is very wide, such as hazelnut, walnut, cashew, almond, etc., high separation efficiency, but also greatly improve the efficiency of nut processing pre-treatment.

Why use a separator?

Most nuts have very hard shells, and this is because nut plants have long protected their seeds from natural disasters.

So, to crack the hard shell of a nut, you need to use a nut sheller.

The sheller first breaks the shell of the nut, and then part of the nut separates directly from the shell, resulting in the kernel.

But there are still parts of the nut that are not completely separated from the shell. So a separator need to reprocess the nuts at this time.

After the vibration and screening of the shell kernel separator. The incomplete nuts and shells will be completely separated and discharged from different outlets. Which is more conducive to recycling.

The widespread application of shell and kernel separation machine

This kind of shell kernel separator can form different production lines with different machines, such as walnut kernel processing line, cashew snack production line and so on.

However, any production line needs to be decided according to the actual production situation and scale. Of course, we will also help you to work out the optimal configuration plan.

Notes for the separating machine use

Be sure to check the parts of the machine carefully before use whether there is loose phenomenon, and timely correction.

Clean the attachment on the screen before and after use in time. So as not to affect the normal operation of the machine.

Maintain the separator regularly to extend its service life.

Cut off the power supply when the machine is not in use.