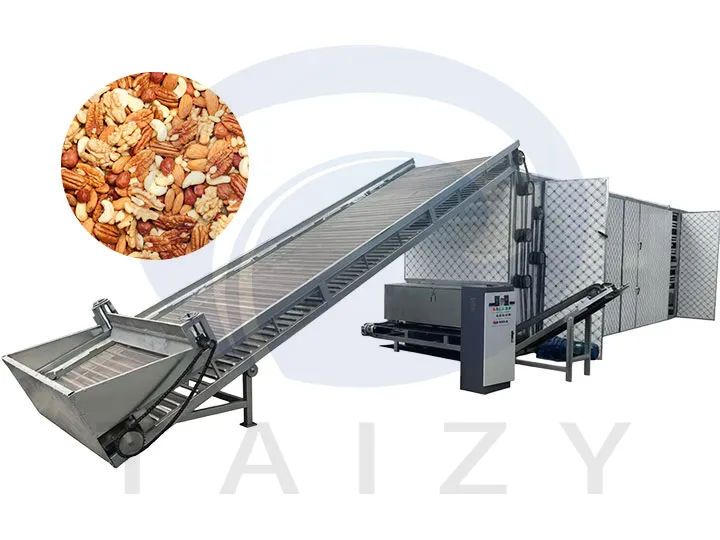

A hot air circulating drying oven is a kind of drying equipment. It can be used for drying different kinds of materials, such as common Chinese medicine, fruit, nuts, and so on. In addition, this kind of equipment is also very intelligent, with a constant temperature effect, and the drying effect of materials is ideal.

The drying trays in this type of hot air circulating drying oven can be made of food-grade stainless steel or plastic, offering excellent corrosion resistance, high structural strength, and long service life, while fully complying with food hygiene standards. The machine is also equipped with an intelligent automatic control system, enabling precise temperature regulation and one-touch operation, significantly reducing labor costs.

The drying machine offers a single-batch capacity ranging from 300 to 8,000 kg, which can be flexibly configured according to different materials and production scales. It supports multiple heating methods, including coal-fired, electric, and heat pump systems, making it adaptable to various processing environments and energy conditions.

Application of Hot Air Circulating Drying Oven

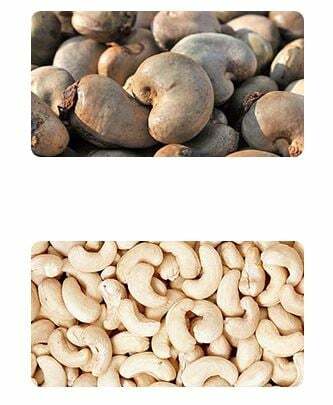

This machine can be used in the processing line of cashew nuts. After grading cashews, a dryer is used. Since the kernels of freshly picked cashews are tightly attached to the husks, it is inefficient to open the cashews at this time.

The purpose of the drying machine is to dry cashew nuts, according to the principle of heat expansion and cold contraction, so that the nuts naturally separate from the shell, making it more convenient for the next cashew shell opening and separating.

Main Applicable Materials

Nuts: Peanuts (with shell), almonds, walnuts, cashews, hazelnuts, etc.

Fruits: Jujubes, papaya slices, hawthorn slices, apple slices, lemon slices, kiwi, mulberries, etc.

Vegetables: Asparagus, carrots, green beans, lentils, eggplant, red peppers, chili peppers, cucumber slices, mushrooms, shiitake, ginger slices, garlic slices, etc.

Herbs & Medicinal Materials: Honeysuckle, nasturtium, burdock, ginseng, mulberries, etc.

Key Advantages of the Nuts Drying Machine

High-Efficiency and Stable Drying Performance

The drying chamber features a fully enclosed structure combined with a forced hot-air circulation system, ensuring uniform heat distribution throughout the chamber. This allows nuts to be dried evenly inside and out. Continuous operation or timed batch drying is supported, improving drying efficiency by over 30% compared with sun drying or conventional drying methods, and significantly shortening processing time.

Consistent Drying Quality and High Yield

An intelligent temperature and humidity control system enables precise adjustment of drying parameters for different nut varieties such as peanuts, almonds, cashews, and hazelnuts. This prevents over-drying or under-drying, effectively reducing cracking, discoloration, and flavor loss, and ensuring consistent appearance and taste.

Wide Applicability for Multiple Materials

In addition to nut drying, the drying chamber is suitable for agricultural products, aquatic products, medicinal herbs, wood, and selected industrial components. One system supports multiple applications, maximizing equipment utilization.

Energy-Saving and Environmentally Friendly

Multiple heating options are available, including heat pump, electric heating, and natural gas, allowing flexible selection based on local energy conditions. High thermal efficiency and low energy consumption support clean, low-carbon production, making the system ideal for long-term operation in nut processing plants.

High Level of Automation, Easy Operation

Optional PLC or touchscreen control systems provide fully automatic management of heating, temperature control, dehumidification, and timing. This reduces labor requirements, minimizes human error, and improves overall production stability.

Hygienic and Food-Safe Design

The drying process generates no exhaust gas, wastewater, or solid pollution. The inner chamber and trays can be made of food-grade stainless steel, compliant with GMP and food safety standards, suitable for export-grade nut processing.

Flexible Structure with Customization Options

The chamber size, batch capacity, number of trays, and internal configuration can be customized according to nut type and production capacity, meeting the needs of small workshops as well as medium and large-scale nut processing lines.

Compact Footprint and Easy Installation

With a modular design and small footprint, the drying chamber is easy to transport, install, and maintain, making it ideal for facilities with limited space or projects requiring fast commissioning.

Parâmetros técnicos

| Modelo | Dimensões (mm) | Drying Trolleys | Drying Capacity per Batch (kg) |

|---|---|---|---|

| SL-2 | 4000 × 1860 × 2500 | 2 | 300–600 |

| SL-4 | 6000 × 1860 × 2500 | 4 | 500–1000 |

| SL-6 | 7200 × 2300 × 2500 | 6 | 800–1500 |

| SL-8 | 8500 × 2300 × 2500 | 8 | 1000–2000 |

| SL-10 | 10000 × 2300 × 2500 | 10 | 1200–2500 |

| SL-12 | 8500 × 3300 × 2500 | 12 | 2500–4000 |

| SL-18 | 8500 × 5000 × 2500 | 18 | 4000–6500 |

| SL-24 | 12000 × 5000 × 2500 | 24 | 5000–8000 |

If you want to know how to choose the right drying machine, please contact us at any time. We will match the most suitable machine for you based on your needs.

Precautions for Using the Hot Air Circulating Drying Oven

- O equipamento deve prestar atenção ao nível do solo durante a instalação

- The first use must pay attention to whether the fan steering is correct

- A secadora deve evitar contato com materiais inflamáveis e explosivos

- Check the sealing strip of the oven regularly and replace it in time

Por que escolher a Taizy?

- Certified Quality: ISO9001 and CE certified, tested by SGS and TUV.

- Reliable & Durable: Built with high-quality materials and advanced design for long-term stable operation.

- Efficient & Energy-Saving: Smart temperature control and hot-air circulation for fast, low-energy drying.

- Easy & Smart Operation: Fully automatic PLC/touchscreen control for simple operation.

- Food-Safe & Eco-Friendly: Food-grade materials, low-carbon, pollution-free, and GMP compliant.

- Complete After-Sales Support: One-year warranty with installation manuals, remote guidance, and optional on-site engineer service.

Produtos Relacionados

If you need continuous processing and large-scale drying, you may want to check out our continuous drying machine.

If you need a machine that can both dry and roast, please take a look at our continuous roasting machine.

Perguntas frequentes

Qual é a temperatura de secagem?

Geralmente cerca de 45 graus. A máquina também é equipada com mesa de controle, o operador pode ajustar a temperatura de secagem de acordo com o teor de água da matéria-prima.

Quanto tempo dura o tempo de secagem?

Normalmente, precisa secar por 8 horas.

Claro, você também pode ajustar o tempo de secagem de acordo com a situação e necessidades reais.

Qual deve ser a espessura das fatias se forem usadas para secar a fruta?

Sugira 3 ~ 5 mm.