Máy bóc vỏ và tách hạt đậu phộng của Taizy dùng để loại bỏ vỏ đậu và tách hạt thành hai nửa. Đậu đã bóc vỏ và cắt đôi có vị ngon, lý tưởng để làm đậu phộng cay, kẹo đậu ngọt, và bơ đậu phộng. Phù hợp cho các nhà máy chế biến đậu, nhà máy thực phẩm và các nơi có nhu cầu cao về hạt đậu.

Máy dễ vận hành. Nó có tỷ lệ bóc vỏ trên 98%, tỷ lệ hư hỏng hạt ≤5%, và cung cấp đậu sạch, trắng, không nhiễm bẩn. Nó hoạt động êm và có công suất 500–1000 kg/h.

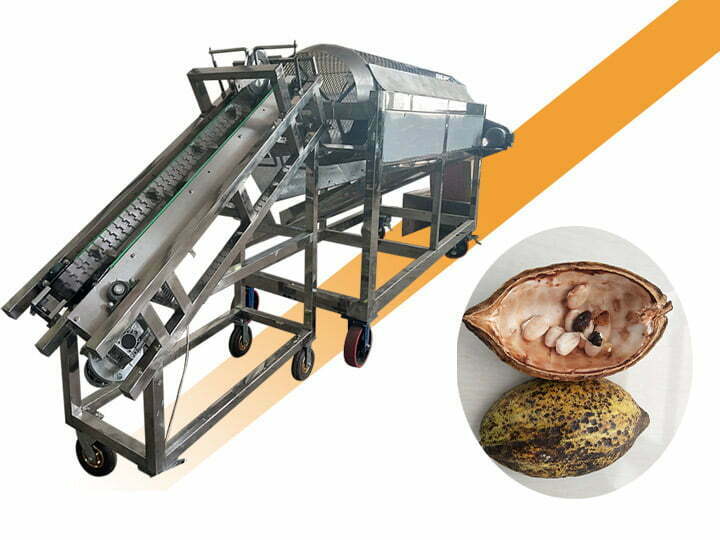

Máy này không chỉ phù hợp cho đậu phộng mà còn cho các loại đậu và một số loại hạt khác, như đậu cacao. Trong dây chuyền chế biến đậu phộng, nó thường được sử dụng sau khi rang để bóc vỏ và tách hạt đậu phộng.

Các loại đậu phù hợp

Máy bóc vỏ và tách hạt đậu phộng có thể xử lý nhiều loại đậu, nhưng để đạt kết quả tốt nhất, nên sử dụng các loại sau:

- Đậu phộng khô

- Đậu phộng rang

- Đậu phộng trung bình

- Đậu phộng không mốc hoặc hư hỏng

Ưu điểm của Máy Tách Vỏ và Cắt Nửa Đậu Phộng

Lột vỏ triệt để, chia đều thành hai nửa

- Sử dụng bánh xe ma sát hoặc cơ chế tách để loại bỏ vỏ đỏ hoàn toàn và tách đậu phộng đều, tỷ lệ vỡ thấp (≤5%).

Xử lý liên tục, nâng cao hiệu quả

- Tích hợp lột vỏ, tách đôi, loại bỏ bụi và sàng rung để sản xuất liên tục tốc độ cao. Có thể xử lý 500–1000 kg/h, giảm đáng kể chi phí lao động.

Ứng dụng rộng rãi

- Xử lý đậu phộng sống hoặc rang với các kích cỡ khác nhau, phù hợp cho kẹo đậu phộng, bơ đậu phộng, snack rang và các sản phẩm đậu phộng khác.

Chất liệu đạt tiêu chuẩn thực phẩm và vệ sinh

- Tất cả các bộ phận tiếp xúc với đậu phộng đều làm bằng thép không gỉ, dễ làm sạch, đáp ứng tiêu chuẩn vệ sinh thực phẩm để đảm bảo an toàn sản phẩm.

Tiết kiệm năng lượng và thân thiện với môi trường

- Xử lý khô bằng ma sát cơ học; không cần nước hoặc nhiệt. Tiêu thụ điện năng thấp và quá trình xử lý sạch sẽ giảm thiểu sử dụng tài nguyên.

Dễ vận hành và bảo trì

- Thiết kế nhỏ gọn với các bộ phận chính có thể tháo rời, dễ làm sạch và bảo trì. Vận hành ổn định với tiếng ồn thấp, phù hợp sử dụng lâu dài.

Độ tin cậy cao và độ bền

- Được trang bị bánh xe cao su hoặc thép chịu lực cao, động cơ và bạc đạn chất lượng, cùng khung chắc chắn. Tuổi thọ vượt quá 10 năm.

Tương thích với các thiết bị khác

- Có thể sử dụng cùng với máy rang đậu phộng, máy xay, máy đóng gói và nhiều thiết bị khác để xây dựng dây chuyền chế biến đậu phộng từ trung bình đến lớn.

Nguyên lý hoạt động của máy bóc vỏ và tách hạt đậu phộng

Hạt đậu phộng tươi phải được bóc vỏ và rang trước khi đưa vào máy cắt đôi đậu phộng để xử lý tiếp. Sau khi đậu phộng được đưa vào máy, trống lăn bên trong loại bỏ vỏ đỏ qua ma sát, trong khi hệ thống hút bụi chân không đồng thời hút vỏ đậu để giữ sạch nguyên liệu. Đậu phộng đã bóc vỏ sau đó đi qua màn hình rung để phân loại chính xác. Màn hình rung tự nhiên tách đậu thành hai nửa và loại bỏ hạt chưa tách và hạt mầm. Điều này cho phép xử lý liên tục tích hợp bóc vỏ, hút bụi và tách hạt, cho ra đậu vỏ sạch, đều và ít hư hỏng.

Thông số kỹ thuật

| Công suất | 1.5KW | 2.2kw |

| Công suất quạt | 1.5kw | 1.5kw |

| Điện áp | Điện 380V 50Hz 3 pha | Điện 380V 50Hz 3 pha |

| Công suất | 500-600kg/h | 1000kg/giờ |

| Kích thước | 1900x850x1350mm | Kích thước 1900x1150x1350mm |

Lưu ý: Tất cả điện áp có thể tùy chỉnh. Xin liên hệ để biết chi tiết!

Đặc điểm cấu trúc của máy bóc vỏ và tách hạt đậu phộng

Thiết kế nhỏ gọn

Máy có cấu trúc hợp lý, nhỏ gọn, chiếm ít diện tích sàn, dễ định vị và di chuyển.

Công suất motor tùy chọn

Trang bị động cơ chính 1.5 kW hoặc 2.2 kW, linh hoạt lựa chọn dựa trên nhu cầu sản xuất.

Công suất motor tùy chọn

Trang bị động cơ chính 1.5 kW hoặc 2.2 kW, linh hoạt lựa chọn dựa trên nhu cầu sản xuất.

Hệ thống quạt khí hiệu quả cao

Quạt hút 1.5 kW cung cấp lực hút mạnh để loại bỏ vỏ đỏ đậu phộng hiệu quả, nâng cao độ sạch của sản phẩm cuối cùng.

Cấu trúc xử lý tích hợp

Máy gồm các trục ma sát, hệ thống hút bụi và màn hình rung, cho phép bóc vỏ liên tục, loại bỏ vỏ, tách hạt và phân loại.

Công suất xử lý cao

Vận hành ổn định với công suất 500–1000 kg/h, phù hợp cho sản xuất vừa và lớn.

Thiết kế điện ba pha

Sử dụng nguồn điện công nghiệp 380V, 50Hz cho hiệu suất mạnh mẽ và ổn định.

Bảo trì dễ dàng

Các bộ phận chính có thể tháo rời để dễ vệ sinh và bảo trì, đáp ứng yêu cầu vệ sinh của các nhà máy chế biến thực phẩm.

Tại sao cần máy bóc vỏ và tách hạt đậu phộng?

Máy bóc vỏ và tách hạt đậu phộng là thiết bị hiệu quả dành cho chế biến sâu đậu phộng. Nó có thể hoàn thành bóc vỏ và tách hạt cùng lúc, nâng cao năng suất và chất lượng sản phẩm. Máy này chủ yếu cần thiết vì các lý do sau:

Hiệu quả cao hơn và chi phí lao động thấp hơn

- Bóc vỏ và tách hạt thủ công chậm và kém hiệu quả. Máy có thể xử lý hàng trăm kilogram đến hơn một tấn đậu phộng mỗi giờ, giảm nhu cầu lao động và hỗ trợ sản xuất liên tục cho các nhà máy vừa và lớn.

Bóc vỏ sạch hơn và ngoại hình đẹp hơn

- Nó sử dụng phương pháp bóc vỏ ma sát không làm hư hại hạt. Máy có tỷ lệ bóc vỏ cao và tỷ lệ hư hỏng thấp. Đậu thành phẩm mịn màng, đều màu, phù hợp cho xuất khẩu hoặc sản xuất thực phẩm cao cấp.

Tách đều để nâng cao chất lượng sản phẩm

- Máy tách đậu có kích thước và hình dạng đồng nhất, tránh cắt không đều do làm thủ công. Điều này nâng cao tính đồng đều và ngoại hình sản phẩm.

Tổn thất xử lý thấp và năng suất cao

- Máy gây ít hư hỏng cho hạt đậu trong quá trình bóc vỏ. Điều này giảm tỷ lệ hư hỏng và tăng năng suất tổng thể, giúp các nhà máy tiết kiệm chi phí nguyên liệu.

Tiêu chuẩn vệ sinh cao cho nhà máy thực phẩm

- Máy làm bằng thép không gỉ hoặc vật liệu đạt tiêu chuẩn thực phẩm. Dễ vệ sinh, an toàn, hợp vệ sinh, đáp ứng yêu cầu của HACCP, ISO và các tiêu chuẩn ngành thực phẩm khác.

Đa năng, phù hợp cho các sản phẩm đậu phộng khác nhau

Hạt đậu phộng đã bóc vỏ và cắt đôi có thể dùng để:

- Đậu phộng cay

- Kẹo đậu phộng

- Bơ đậu phộng

- Đậu phộng rang

- Đồ ăn nhẹ hỗn hợp các loại hạt

- Nguyên liệu cho các nhà máy thực phẩm

Tại sao chọn Taizy?

- Kinh nghiệm ngành phong phú: Taizy đã tập trung vào máy móc chế biến hạt và đậu phộng trong nhiều năm, tích lũy công nghệ sản xuất trưởng thành và kinh nghiệm để cung cấp thiết bị ổn định và hiệu quả.

- Giải pháp chuỗi xử lý hoàn chỉnh: Từ Lột vỏ đậu phộng, rang, Lột vỏ, tách đôi, nghiền và đóng gói, Taizy cung cấp dây chuyền sản xuất trọn gói, tiết kiệm thời gian và chi phí phối hợp cho khách hàng.

- Hiệu suất cao và tỷ lệ hư hỏng thấp: Kỹ thuật bóc vỏ và tách hạt bằng ma sát khô đảm bảo công suất cao phù hợp cho các nhà máy vừa và lớn, đồng thời giữ nguyên hạt đậu vỏ và giảm thiểu mất nguyên liệu.

- Vật liệu đạt tiêu chuẩn thực phẩm và tiêu chuẩn vệ sinh: Tất cả các bộ phận tiếp xúc với đậu phộng đều làm bằng thép không gỉ, dễ vệ sinh, đáp ứng yêu cầu vệ sinh thực phẩm, đảm bảo an toàn và chất lượng sản phẩm.

- Tùy chỉnh và dịch vụ chuyên nghiệp: Thiết bị có thể tùy chỉnh dựa trên nhu cầu sản xuất, phương pháp chế biến và điều kiện xưởng. Taizy cung cấp thiết kế dây chuyền, lắp đặt, vận hành thử và hỗ trợ hậu mãi toàn diện.

- Kinh nghiệm và độ tin cậy của thị trường quốc tế: Sản phẩm của Taizy được xuất khẩu sang nhiều quốc gia và khu vực, được hỗ trợ bởi hệ thống quản lý chất lượng trưởng thành và mạng lưới hậu mãi, mang lại sự yên tâm cho khách hàng.

Chúng tôi cũng cung cấp các dây chuyền chế biến đậu phộng hoàn chỉnh như sau. Xin liên hệ để biết thêm thông tin.

Bao bì vận chuyển