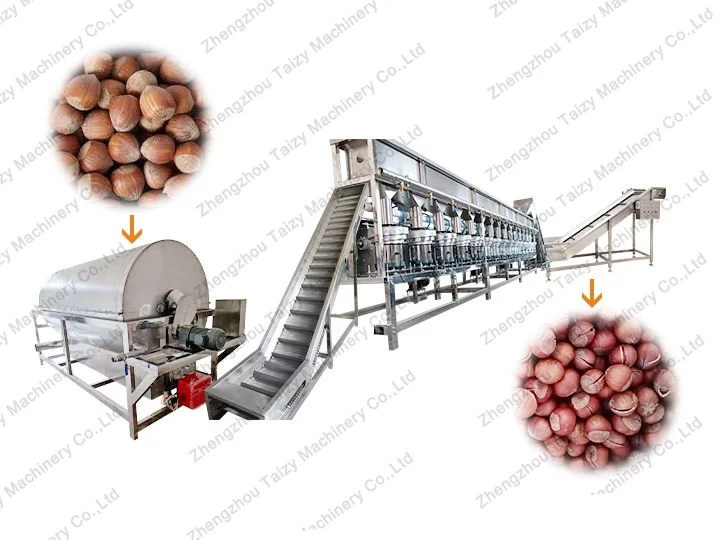

Tam otomatik antep fıstığı kabuk kırma üretim hattı , kabukların verimli şekilde çıkarılması ve kabuk-çekirdek ayrımı için tasarlanmış sürekli bir işleme sistemidir. Sınıflandırma, hassas kabuk kırma ve verimli ayırma entegrasyonu ile ham maddeden bitmiş çekirdeğe otomatik işlem sağlar. Hat, temel antep fıstığı işleme ve ön işleme uygundur.

Antep fıstığı kabukları ince ama dayanıklıdır ve çekirdekler kırılgandır, yüksek kabuk kırma doğruluğu ve uniform besleme gerektirir. Bu üretim hattı, antep fıstığı özelliklerine göre yapısal olarak optimize edilmiştir. Yüksek kabuk kırma oranı sağlar ve çekirdek kırılmasını düşük tutar, ürün kalitesini istikrarlı kılar.

Saatte 100kg kapasite ile, hat, antep fıstığı işleme tesisleri, kuruyemiş ihracat fabrikaları ve ham madde ön işleme atölyelerinde derin işleme için yaygın olarak kullanılır.

Uygulanabilir Ham Maddels

- Kabuk içi antep fıstığı — ana işleme hedefi

İşleme İpuçları:

En iyi kabuk kırma sonuçları için, malzemeler kuru ve temiz olmalıdır. Taşlar, metal veya diğer yabancı maddelerden kaçının. Boyut ve sertliğe göre ayar yapın.

Antep Fıstığı Kabuk Kırma Üretim Hattı Süreci

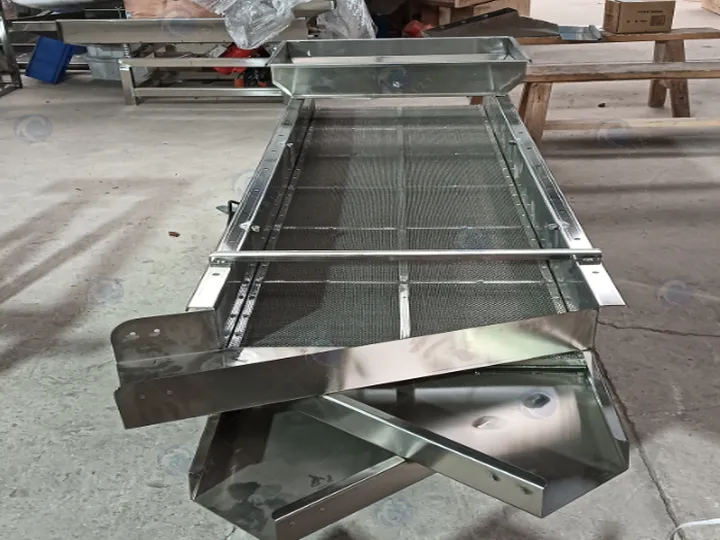

Pistachio Grading (Three-Layer Grading Screen)

Raw in-shell pistachios are first fed into the three-layer grading screen for size classification.

The machine is equipped with three screening layers, allowing pistachios to be separated into three different size grades. This ensures uniform feeding in the shelling process and effectively reduces kernel breakage caused by size variation.

- Grading levels: 3 sizes

- Machine size: 2000 × 600 × 1100 mm

- Power: 0.4 kW

Proper grading significantly improves shelling stability and helps maintain a higher whole-kernel rate.

Pistachio Shelling (Pistachio Shelling Machine)

After grading, pistachios are conveyed to the pistachio shelling machine for cracking.

The machine is fitted with a variable-speed motor, allowing the operating speed to be adjusted according to pistachio size and shell hardness, ensuring consistent shell opening performance.

- Motor power: 2.6 kW

- Voltage: 380 V / 50 Hz

- Capacity: approx. 120 kg/h

- Shell opening rate: ≥95%

- Kernel breakage rate: ≤8%

- Material: stainless steel

- Machine dimensions: 3.2 × 1 × 1.9 m

After shelling, the mixture of kernels and shells is transferred to the separation stage.

Kernel–Shell Separation (Air Separator / Dehulling Machine)

The shelled mixture is processed by a pneumatic kernel–shell separator.

By utilising the density difference between pistachio kernels and shells, the machine combines airflow and screening to achieve efficient separation.

- Güç: 1.1 kW

- Voltage: 380 V / 50 Hz

- Overall size: 0.9 × 0.9 × 1.6 m

- Separation method: gravity + air flow

- Separation efficiency: 90–95%

Separated pistachio kernels can be sent directly for packaging or further processing, while empty shells are discharged separately.

Antep Fıstığı Kabuk Kırma Hattının Temel Avantajları

Designed for Pistachio Shelling Characteristics

Based on the thin yet tough shell structure of pistachios and their fragile kernels, the line combines three-layer grading with variable-speed shelling. This ensures pistachios of different sizes are cracked under matched operating conditions, reducing unnecessary kernel damage.

Stable Output for Small and Medium-Scale Processing

The production line is designed for an output of approximately 100 kg/h, featuring a compact layout and low energy consumption. It is well-suited for small pistachio processing plants, pilot production lines, and initial investment projects.

High Shell Opening Rate with Controlled Breakage

With uniform feeding and adjustable shelling speed, the line achieves a shell opening rate of ≥95%, while keeping the kernel breakage rate at ≤8%, ensuring a good balance between efficiency and product quality.

Efficient Kernel–Shell Separation

The air-based kernel–shell separator uses gravity and airflow separation, achieving a separation efficiency of 90–95%. Kernels and shells are discharged separately, significantly reducing manual sorting.

Food-Grade Materials for Safe Processing

Key components in contact with pistachios are made of stainless steel, meeting food processing hygiene standards. The structure is corrosion-resistant, easy to clean, and suitable for long-term food-grade operation.

Simple Configuration with Cost-Effective Investment

The line consists of grading, shelling, and separation units, requiring minimal installation space and maintenance. It offers a cost-effective solution for customers seeking reliable pistachio shelling at a moderate capacity.

100kg/h Fully Automatic Pistachio Shelling Proessing Line

Makine listesi

| Hayır. | Ekipman Adı (İngilizce) | Miktar |

|---|---|---|

| 1 | Pistachio Three-Layer Grading Screen | 1 birim |

| 2 | Antep Fıstığı Kabuk Kırma Makinesi | 1 birim |

| 3 | Air-Type Kernel–Shell Separator | 1 birim |

Makine Özellikleri

| Hayır. | Makine Adı | Teknik Parametreler |

|---|---|---|

| 1 | Pistachio Three-Layer Grading Screen | Machine size: 2000 × 600 × 1100 mm Power: 0.4 kW Screen layers: 3 layers (3 size grades) |

| 2 | Antep Fıstığı Kabuk Kırma Makinesi | Motor: Variable-speed motor Power: 2.6 kW Voltage: 380 V / 50 Hz Capacity: approx. 120 kg/h Shell opening rate: ≥95% Kernel breakage rate: ≤8% Machine size: 3.2 × 1 × 1.9 m Packing size: 3.7 × 1.1 × 2 m Malzeme: Paslanmaz çelik Weight: approx. 260 kg |

| 3 | Air-Type Kernel–Shell Separator | Güç: 1.1 kW Voltage: 380 V / 50 Hz Overall size: 0.9 × 0.9 × 1.6 m Separation method: gravity + air flow Separation efficiency: 90–95% |

Küresel Uygulamalar & Müşteri Tanıma

The fully automatic pistachio shelling production line has been successfully applied in nut processing projects across Africa, Central Asia, Eastern Europe, and other regions. Customers highly praise its stability, processing efficiency, and product quality.

Verimli, güvenilir ve ölçeklenebilir bir antep fıstığı kabuk kırma çözümü arıyorsanız, detaylı konfigürasyonlar ve teknik destek için bizimle iletişime geçin.