A linha de produção de pistáchio totalmente automática é um sistema de processamento contínuo projetado para remoção eficiente de casca e separação de núcleo de pistáchios com casca. Integra classificação, descasque preciso e separação eficiente para processamento automatizado desde pistáchios crus até núcleos acabados. A linha é adequada para processamento primário de pistáchios e pré-tratamento antes de processamento adicional.

As cascas de pistáchio são finas, mas resistentes, e os núcleos são frágeis, exigindo alta precisão de descasque e alimentação uniforme. Esta linha de produção é otimizada estruturalmente para as características do pistáchio. Oferece uma alta taxa de descasque enquanto mantém a quebra de núcleo baixa, garantindo qualidade estável do produto.

With a capacity of 100kg per hour, the line is widely used in pistachio processing plants, nut export factories, and raw material pre-processing workshops for nut deep processing.

Matéria-prima aplicávells

- Pistáchios com casca — principal alvo de processamento

Dicas de Processamento:

Para melhores resultados de descasque, os materiais devem estar secos e limpos. Evite pedras, metais ou outros objetos estranhos. Ajuste as configurações com base no tamanho e dureza.

Processo da Linha de Produção de Casca de Pistáchio

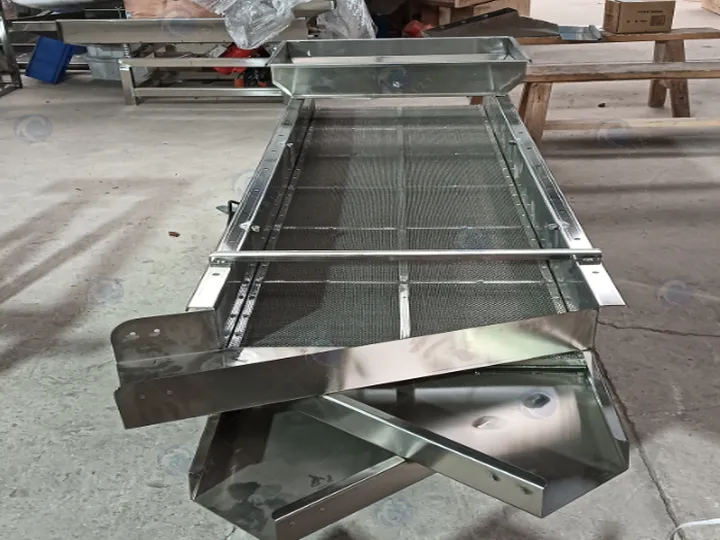

Pistachio Grading (Three-Layer Grading Screen)

Raw in-shell pistachios are first fed into the three-layer grading screen for size classification.

The machine is equipped with three screening layers, allowing pistachios to be separated into three different size grades. This ensures uniform feeding in the shelling process and effectively reduces kernel breakage caused by size variation.

- Grading levels: 3 sizes

- Machine size: 2000 × 600 × 1100 mm

- Power: 0.4 kW

Proper grading significantly improves shelling stability and helps maintain a higher whole-kernel rate.

Pistachio Shelling (Pistachio Shelling Machine)

After grading, pistachios are conveyed to the pistachio shelling machine for cracking.

The machine is fitted with a variable-speed motor, allowing the operating speed to be adjusted according to pistachio size and shell hardness, ensuring consistent shell opening performance.

- Motor power: 2.6 kW

- Voltage: 380 V / 50 Hz

- Capacity: approx. 120 kg/h

- Shell opening rate: ≥95%

- Kernel breakage rate: ≤8%

- Material: stainless steel

- Machine dimensions: 3.2 × 1 × 1.9 m

After shelling, the mixture of kernels and shells is transferred to the separation stage.

Kernel–Shell Separation (Air Separator / Dehulling Machine)

The shelled mixture is processed by a pneumatic kernel–shell separator.

By utilising the density difference between pistachio kernels and shells, the machine combines airflow and screening to achieve efficient separation.

- Potência: 1.1 kW

- Voltage: 380 V / 50 Hz

- Overall size: 0.9 × 0.9 × 1.6 m

- Separation method: gravity + air flow

- Separation efficiency: 90–95%

Separated pistachio kernels can be sent directly for packaging or further processing, while empty shells are discharged separately.

Vantagens principais da linha de produção de casca de pistáchio

Designed for Pistachio Shelling Characteristics

Based on the thin yet tough shell structure of pistachios and their fragile kernels, the line combines three-layer grading with variable-speed shelling. This ensures pistachios of different sizes are cracked under matched operating conditions, reducing unnecessary kernel damage.

Stable Output for Small and Medium-Scale Processing

The production line is designed for an output of approximately 100 kg/h, featuring a compact layout and low energy consumption. It is well-suited for small pistachio processing plants, pilot production lines, and initial investment projects.

High Shell Opening Rate with Controlled Breakage

With uniform feeding and adjustable shelling speed, the line achieves a shell opening rate of ≥95%, while keeping the kernel breakage rate at ≤8%, ensuring a good balance between efficiency and product quality.

Efficient Kernel–Shell Separation

The air-based kernel–shell separator uses gravity and airflow separation, achieving a separation efficiency of 90–95%. Kernels and shells are discharged separately, significantly reducing manual sorting.

Food-Grade Materials for Safe Processing

Key components in contact with pistachios are made of stainless steel, meeting food processing hygiene standards. The structure is corrosion-resistant, easy to clean, and suitable for long-term food-grade operation.

Simple Configuration with Cost-Effective Investment

The line consists of grading, shelling, and separation units, requiring minimal installation space and maintenance. It offers a cost-effective solution for customers seeking reliable pistachio shelling at a moderate capacity.

100kg/h Fully Automatic Pistachio Shelling Proessing Line

Lista de máquinas

| Não. | Nome do equipamento (Inglês) | Quantidade |

|---|---|---|

| 1 | Pistachio Three-Layer Grading Screen | 1 unidade |

| 2 | Máquina de Casca de Pistáchio | 1 unidade |

| 3 | Air-Type Kernel–Shell Separator | 1 unidade |

Especificações da máquina

| Não. | Nome da Máquina | Parâmetros técnicos |

|---|---|---|

| 1 | Pistachio Three-Layer Grading Screen | Machine size: 2000 × 600 × 1100 mm Power: 0.4 kW Screen layers: 3 layers (3 size grades) |

| 2 | Máquina de Casca de Pistáchio | Motor: Variable-speed motor Power: 2.6 kW Voltage: 380 V / 50 Hz Capacity: approx. 120 kg/h Shell opening rate: ≥95% Kernel breakage rate: ≤8% Machine size: 3.2 × 1 × 1.9 m Packing size: 3.7 × 1.1 × 2 m Material: Aço inoxidável Weight: approx. 260 kg |

| 3 | Air-Type Kernel–Shell Separator | Potência: 1.1 kW Voltage: 380 V / 50 Hz Overall size: 0.9 × 0.9 × 1.6 m Separation method: gravity + air flow Separation efficiency: 90–95% |

Aplicações Globais & Reconhecimento dos Clientes

The fully automatic pistachio shelling production line has been successfully applied in nut processing projects across Africa, Central Asia, Eastern Europe, and other regions. Customers highly praise its stability, processing efficiency, and product quality.

Se procura uma solução eficiente, fiável e escalável para descasque de pistáchio, contacte-nos para configurações detalhadas e suporte técnico.