The coated peanut production line can efficiently and stably process peanuts into powdered or flavored coated peanuts. With a high level of automation, it provides a one-stop production solution from raw material handling to finished product packaging.

Taizy’s coated peanut production line can process peanuts, broad beans, cashews, macadamia nuts, and other nut and legume snacks. The entire line requires minimal operators, significantly reducing labor costs while improving production efficiency.

The final coated peanuts have even coating, excellent taste, and an attractive appearance, making them popular with consumers and an ideal choice for many food factories.

Taizy’s production line can produce 100–500 kg per hour, meeting the needs of many small and medium-sized enterprises. All components used in the full production process are made of high-quality stainless steel to ensure food safety and hygiene, and they are easy to clean.

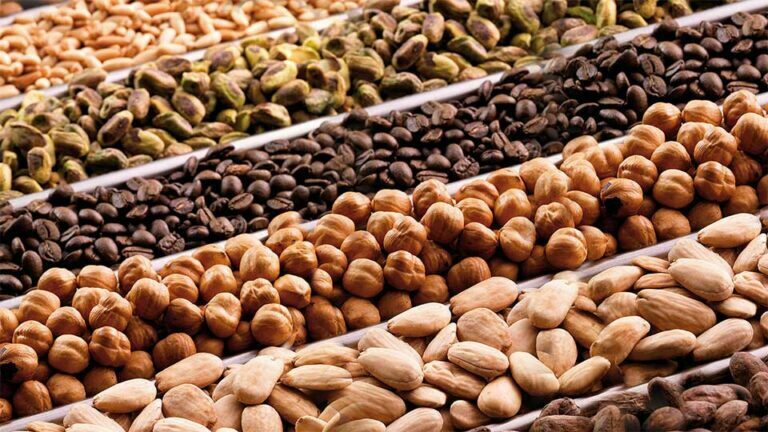

Types of Coated Peanuts Produced by the Line

- Peanuts: Sugar-coated peanuts, honey peanuts, spicy peanuts, chocolate peanuts, etc.

- Legumes: Coated broad beans, green peas, peas, edamame, etc.

- Nuts: Coated cashews, macadamia nuts, sunflower seeds, etc.

- Snack Extensions: Spicy crisps, puffed snacks, chocolate-coated beans, seafood-coated snacks, etc.

All products feature uniform coating, smooth surfaces, and a crispy texture, making them widely popular in the market.

Coated Peanut Production Process

The main equipment for coated peanut production includes a peanut roasting machine, dry peanut peeling machine, peanut coating machine, swing roasting oven, seasoning machine, coated peanut cooling machine, and fully automatic packaging machine. Together, they enable rapid production of coated peanuts.

Raw Material Roasting

The first step in coated peanut production is roasting the peanuts to remove moisture, enhance aroma and taste, and reduce breakage.

Equipment: Peanut Roasting Machine

- Drum-type design ensures even heating and prevents burning

- Moisture can be reduced below 5%

- Heating options: electric, gas, or coal

| မော်ဒယ် | Dimensions (mm) | Capacity (kg/h) | စွမ်းအင် (ကီလိုဝတ်) | Electric Heating (kW) | Gas Heating (kg) |

|---|---|---|---|---|---|

| TZ-1 | 3000×1200×1700 | 80–120 | 1.1 | 18 | 2–3 |

| TZ-2 | 3000×2200×1700 | 180–250 | 2.2 | 35 | 4–6 |

| TZ-၃ | 3000×3300×1700 | 280–350 | 3.3 | 45 | 6–8 |

| TZ-4 | 3000×4400×1700 | 380–450 | 4.4 | 60 | 8–10 |

| TZ-၅ | 3000×5500×1700 | 500–650 | 5.5 | 75 | 10–12 |

Working Video

ငှက်ပျောသီး အရေပြားဖျက်ခြင်း

After roasting, peanuts enter a dry peeling machine to separate the kernels from the skins. Peeling rate can reach over 96%, providing a solid base for uniform coating.

Equipment: Dry Peanut Peeling Machine

- Capacity: approx. 200–250 kg/h

- Compact structure, easy operation

| မော်ဒယ် | ထုတ်လုပ်မှု (ကီလိုဂရမ်/နာရီ) | Motor Power (kW) | Fan Power (kW) | ဗို့အား | Frequency (Hz) | Threshing Performance | Half-Kernel Rate | အရွယ်အစား (မီလီမီတာ) |

|---|---|---|---|---|---|---|---|---|

| TZ-1 | 200–300 | 0.55 | 0.37 | 380V/220V | 50 | >98% | ≤5% | 1100×400×1100 |

| TZ-2 | 400–500 | 0.55×2 | 0.37 | 380V/220V | 50 | >98% | ≤5% | 1100×700×1100 |

| TZ-၃ | 600–800 | 0.55×3 | 0.37 | 380V/220V | 50 | >98% | ≤5% | 1100×1000×1100 |

| TZ-4 | 800–1000 | 0.55×4 | 0.37 | 380V/220V | 50 | >98% | ≤5% | 1100×1400×1100 |

Powder Coating (Coating)

Peeled peanuts enter a peanut coating machine or coating-forming machine. Under centrifugal force, peanuts tumble continuously while sugar or seasoning powders are gradually added for even coating.

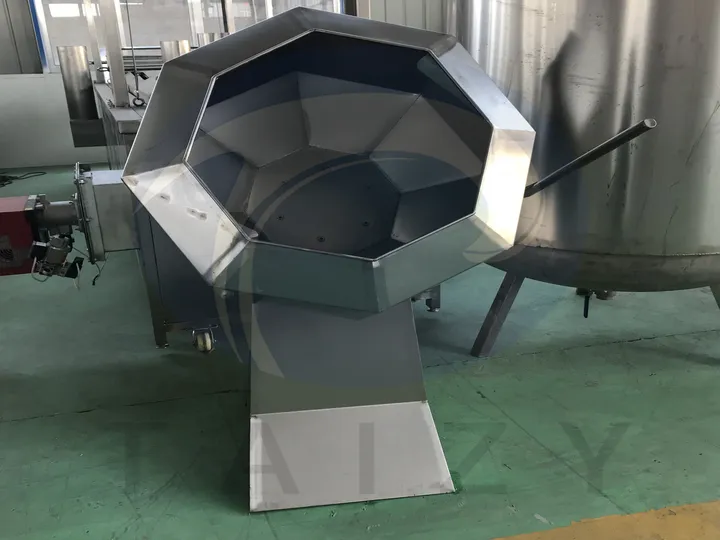

Equipment: Peanut Coating Machine

- Internal rolling and friction ensure uniform mixing with the powder

- Coating thickness is controllable for a smooth appearance

- High automation reduces manual labor

| Parameter | အသွားအလာအချက်အလက်များ |

|---|---|

| ဓာတ်အား | 1.1 kW / 380V, 220V |

| အလေးချိန် | 180 kg |

| အတိုင်းအတာများ | 1200×1000×1300 mm |

| Diameter | 1000 mm |

Roasting to Fix Coating

Coated peanuts are baked in a rotary roasting machine to fix the sugar or seasoning coating, making it firm and crispy.

Equipment: Peanut Rotary Roasting Machine

- Easy operation, baking time approx. 15 minutes

- Electric or gas heating is optional

- The rotating drum ensures even and stable heating

| Parameter | အသွားအလာအချက်အလက်များ |

|---|---|

| ဓာတ်အား | 25.75 kW |

| ဗို့အား | 380V / 50 Hz |

| အတိုင်းအတာများ | 2200×2000×1500 mm |

| အပူပေးမှု အင်အား | 25 kW |

| Swing Power | 0.75 kW |

| အလေးချိန် | 500 kg |

| Speed | 40–60 cycles/min |

Working Video

Seasoning (Optional)

For flavored peanuts, a seasoning machine adds salt, chili powder, chocolate powder, or other seasonings to diversify flavors.

Equipment: Peanut Seasoning Machine

- Can be connected to a spraying system or manual addition

- Ensures even mixing to prevent uneven seasoning

- Capacity: approx. 300 kg/h

| Parameter | အသွားအလာအချက်အလက်များ |

|---|---|

| ဓာတ်အား | 1.1 kW / 380V |

| အလေးချိန် | 150 kg |

| အတိုင်းအတာများ | 1000×800×1300 mm |

| Barrel Diameter | 1000 mm |

| စွမ်းရည် | 300 kg/h |

Cooling

Roasted and seasoned peanuts pass through a cooling machine to reduce temperature, set the coating, prevent sticking, and prepare for packaging.

Equipment: Peanut Cooling Machine

- Air cooling or air storage combination

- Adjustable airflow for rapid cooling

- Capacity: approx. 200–300 kg/h

| မော်ဒယ် | Capacity (kg/h) | Fan Power (kW) | Voltage / Frequency | Dimensions (mm) |

|---|---|---|---|---|

| TP-1 | 200–300 | 1.1 | 380V/220V, 50 Hz | 1300×600×600 |

Automatic Packaging

Cooled peanuts are packed using a packaging machine according to customer requirements, ensuring hygiene, neatness, and convenient transportation.

Equipment: Peanut Granule Packaging Machine

- Suitable for bags, boxes, or jars

- Packing speed: 37–100 packs/min

- Adjustable filling range: 22–220 ml

| Parameter | အသွားအလာအချက်အလက်များ |

|---|---|

| Packaging Type | Back-seal (customizable) |

| Packing Speed | 37–72 bags/min or 50–100 bags/min |

| Bag Length | 30–180 mm |

| Filling Range | 22–220 ml |

| Power Consumption | 1.8 kW |

| အလေးချိန် | 250 kg |

| အတိုင်းအတာများ | 650×1050×1950 mm |

| ကာတွန်းအရွယ်အစား | 1100×750×1820 mm |

အဆီလိပ်ထားသော ပဲထုတ်လုပ်မှုလိုင်း၏ အားသာချက်များ

- Full Automation: Integrates roasting, peeling, coating, baking, seasoning, cooling, and packaging with minimal labor.

- Keefisienan Tinggi: Stable production with capacities from 100–500 kg/h and fast, continuous operation.

- Consistent Quality: Even coating, crispy texture, smooth glossy appearance, and low breakage.

- Versatile: Suitable for peanuts, nuts, and legumes; supports sugar-coated, honey, spicy, chocolate, and other flavors.

- Hygienic & Easy to Maintain: 不锈钢接触部分易于清洁。

- Customizable & Scalable: Different models and heating options; adjustable packaging for bags, boxes, or jars.

- Professional Support: On-site assembly, training, spare parts, technical support, and working videos provided.

အဖုံးလိပ်ပြားလုံးထုတ်လုပ်ရေးလိုင်းရဲ့ ဗီဒီယို

အရသာထည့်ထားသော ပဲများ အထူးသဖြင့် ဘာကြောင့် လူကြိုက်များလဲ?

Wrapped peanut has the characteristics of a sweet and delicious, crisp taste. Initially, wrapped clothes peanut only has a simple, plain, spicy, sweet taste, the basis of these simple but with the constant innovation of wrapped clothes peanut technology. More and more new tastes have also been developed, such as cocoa peanuts, purple potato honey peanuts, and even seafood flavour peanuts, etc. The emergence of numerous flavours will give consumers more choices of space, consumers can choose according to his be fond.

Of course, in addition to the diversity of taste, the wrapped peanut is also gradually improved in appearance and even colour. Its main production methods include dough wrapping, pulp wrapping, spraying, crushing, and other ways. The process will undoubtedly be more visually appealing, which is why the peanut is so popular because it combines the advantages of delicious taste with the advantages of attracting consumers.

The coated peanut production line is a complete production line for peanut wrapping. The peanut needs to go through a number of processes, including baking, peeling, wrapping, re-baking, cooling, and seasoning. Finally, the finished product only needs to be packaged.