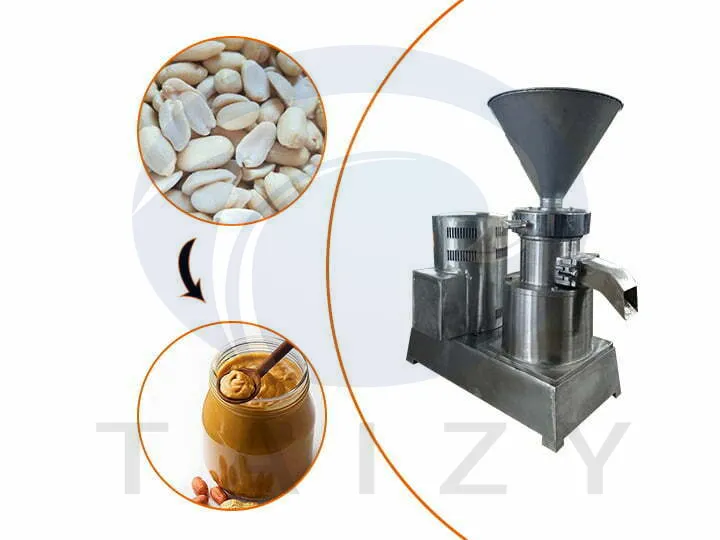

A colloid mill is a common machine for making peanut butter. It is the special mechanical equipment for refining fluid materials. It is usually made of carbon steel and stainless steel. In addition to the production of peanut butter, but also widely used in food, medicine, chemicals, cosmetics, light industry plastics, and other industries.

There are many ways to eat peanut butter

Peanut butter is not only delicious, it can be eaten in many ways. Direct consumption can be daubed in bread, steamed buns, and peanut butter is more widely used in food ingredients, such as noodles, cucumber, fried vegetables, do hot pot dipping material, and so on, widely loved by the public.

The operation principle of colloid mill is introduced

Making peanut butter colloid mill through different geometric shapes of the stator and rotor rotating at high-speed relative motion, groundnut kernels under dead weight, the effect of gas pressure and centrifugal force, then through the variable annular clearance by powerful shear force, friction force, impact force, the role of the high-frequency vibration and other complex force, the peanut can be effectively dispersed, crushing, emulsifying, mixing, to get the best quality peanut butter.

Under normal circumstances, the granularity of peanuts can reach 2-60 microns and the homogeneity can reach more than 95% after processing by this grinding machine. It is the most ideal equipment for grinding peanut butter.

Types and main technical parameters of commercial colloid mill

| Type | TZ-50 | TZ-85 | TZ-130 | TZ-210 |

| Fineness of object processing(um) | 2-70 | 2-70 | 2-70 | 2-70 |

| Motor power(kw) | 1.5 | 5.5 7.5 | 7.5 11 | 30 |

| Output (self-inflow) r/min | 0.2-0.8 | 0.2-4 | 0.2-6 | 2-6 |

| No-load speed(cm) | 3000±100 | 3000±100 | 3000±100 | 3000±100 |

| Size(cm) | 50*23*70 | 105*30*84 | 127*38.5*102.5 | 120*50*130 |

| Weight(kg) | 60 | 185 | 240 | 600 |

| Remarks | Equipped with cooling system | Equipped with cooling system | Equipped with cooling system | Equipped with cooling system |