The peanut powder milling machine is a food processing device specially designed for chopping, powdering, and granulating dry peanuts. It is suitable for large-scale production of peanut powder, peanut flakes, and similar products. Independently developed and manufactured by Taizy, the machine features a rational structure, easy operation, stable performance, high output, and continuous working capability. It is widely used in food processing factories, seasoning factories, and nut deep-processing industries.

The machine has a capacity of 200–600 kg/h, which can be adjusted according to the raw material condition, desired output fineness, and operating method, making it ideal for small to medium-scale continuous production.

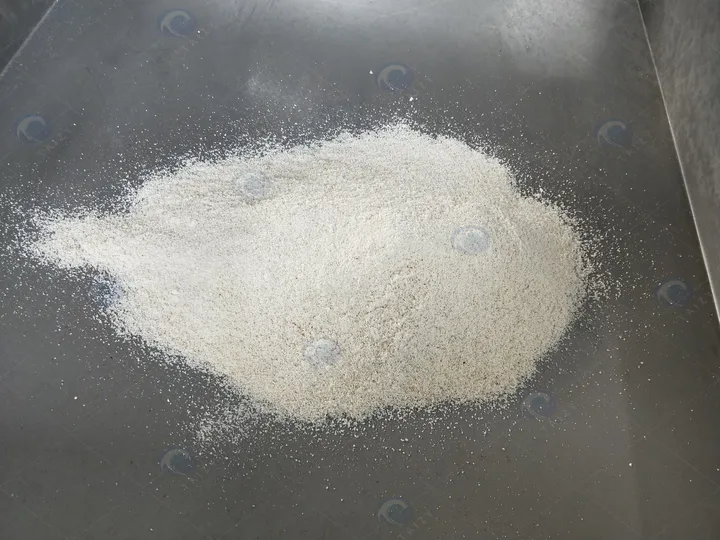

This popular peanut powder milling machine can produce powder in a single pass, requiring no secondary processing. The finished product is dry, non-greasy, retains the natural peanut flavor, and can be flexibly switched between powdering and granulating modes according to production needs.

Functions of the Peanut Powder Milling Machine

Powdering Function

Using a combination of rotary cutting blades and grinding rollers, the machine can process peanuts into fine powder in a single pass. The finished product has uniform particle size without the need for secondary grinding. The minimum powder fineness can reach 40 mesh with 4–6% moisture, or up to 60 mesh for lower-oil content peanuts.

Granulating Function

By activating only the rotary blades and separating grinding rollers, the machine can produce peanuts in various granular sizes, meeting the requirements for peanut flakes, ingredient granules, and other similar products.

Flexible Powder & Granule Processing

The same machine can be flexibly switched between powdering and granulating modes according to production needs, improving equipment utilization and reducing repeated investment

Continuous and Efficient Production

Supports continuous feeding and discharging, with a stable output of 200–600 kg/h, suitable for small to medium-scale food processing factories.

Dry Processing

Entirely oil-free during operation, the process does not produce oil or stickiness. The finished product is dry, clean, and retains the natural flavor and quality of peanuts.

Controllable Particle Size

Through structural adjustment and process control, the machine can produce peanut powder or granules with different fineness, adaptable to various product standards.

Working Principle of the Peanut Powder Making Machine

The peanut powder making machine operates on a “rotary cutting + grinding roller” principle. After entering the machine, peanuts are first chopped at high speed by a two-stage rotary cutting system, then pressed and ground by the grinding rollers to produce uniform, fine peanut powder in a single pass.

If only the rotary cutters and separating rollers are used, the machine can produce peanut granules instead. The entire process is dry, oil-free, and non-sticky. The machine runs stably, delivering dry, high-quality products while ensuring efficient production and flexible output of both powder and granules.

Applicable Raw Materials

This machine is suitable for processing the following raw materials:

- Peeled peanuts

- 烘烤花生

- Dried nuts (mainly peanuts)

No oil is required for the raw materials, and the process produces no greasiness.

技術參數

| 項目 | 規格 |

|---|---|

| 功率 | 3 kW |

| 容量 | 200–600 kg/h |

| 尺寸 | 1200 × 1050 × 1400 mm (up to 1700 mm) |

| 電壓 | 380 V |

| 頻率 | 50 Hz |

The power supply voltage and plug can be customized according to your specific requirements. Multiple models are available—please feel free to contact us for details.

In addition, we also offer wet and dry peanut peeling machines, as well as peanut roasting machines. If you want to produce peanut-based foods, feel free to contact us. We provide a variety of peanut food production lines.

What are the Advantages of the Popular Peanut Powder Milling Machine?

High Efficiency and Matched Power

- Equipped with a 3 kW motor, the machine runs stably at 380 V / 50 Hz with an output of 200–600 kg/h. The power and cutting system are well matched, ensuring high efficiency while minimizing energy waste.

Durable, High-Quality Blades

- Rotary cutters are made of high-strength, food-grade alloy steel and undergo heat treatment. They are hard, wear-resistant, and maintain sharpness during long-term continuous operation, ensuring consistent powdering and granulating performance.

Combined Cutting and Grinding for High-Quality Output

- Two-stage rotary cutters perform efficient coarse chopping, followed by grinding rollers for fine milling. This produces uniform peanut powder or granules that are dry, non-greasy, and retain natural peanut flavor.

Compact Structure and Stable Operation

- With dimensions of approximately 1200 × 1050 × 1400 mm (up to 1700 mm), the machine has a compact layout and stable center of gravity, running with low vibration and noise, suitable for continuous production.

Flexible Processing Modes

- The machine can switch between powdering and granulating modes as needed, meeting different product specifications with a single device and reducing equipment investment.

Low Maintenance and Long Service Life

- The combination of wear-resistant blades and stable transmission reduces the frequency of blade replacement. Routine maintenance is simple, extending the machine’s lifespan and improving overall ROI.