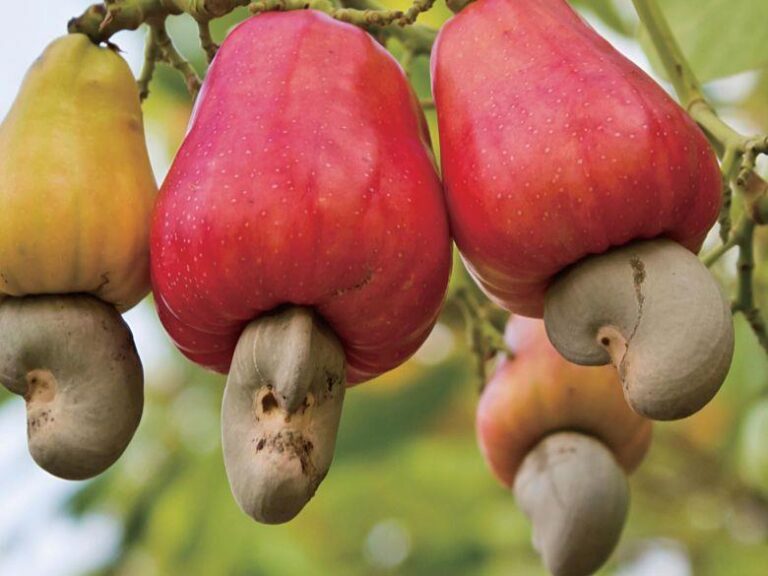

The cashew nut production line is mainly designed to process unshelled cashews into peeled cashew kernels and complete vacuum packaging. The complete line includes grading, cooking, drying, shelling, screening, secondary drying, peeling, kernel grading, roasting, and vacuum packing. With a peeling rate of over 98%, it is highly suitable for cashew processing plants of all sizes.

This cashew klernel production line has a capacity of 100–800 kg/h. According to your production requirements, you can choose between a fully automatic cashew processing line or a semi-automatic cashew processing line. Feel free to contact us for more details and professional consultation.

Process flow of Cashew Nut Production Line

This cashew production line is a complete technological process, which is the preliminary comprehensive processing of cashew after picking. The whole production line adopts semi-automatic operation, compared with the traditional manual processing, the efficiency will be higher, at the same time cashew damage rate will be greatly reduced.

ကာရှူးနတ်ထုတ်လုပ်မှုလိုင်း၏ အလုပ်လုပ်နည်းပညာသည် အောက်ပါစက်များကို လိုအပ်သည်။

ကာရှူးနတ် အဆင့်သတ်မှတ်စက်

First of all, the initial grading of cashews is to facilitate the subsequent opening of the shell. Because the size of cashews varies, the shelling machine uses the distance between the blades to open the shell. So before opening the shell need to ensure that the size of the cashews is uniform.

The size of cashew nuts is generally divided into 16, 18, 20, 22, and 24mm. The grading machine realises the grading processing of cashew nuts through screens with different pore diameters. Customers can choose the number of grades that should be divided according to actual requirements.

Cashew Cooking Machine

The graded cashews are put into the cooking box. According to the size of cashews, the cooking time is different. The cooking time of cashews with smaller volumes is longer, and the cooking time of cashews with smaller volumes is vice versa.

The main purpose of cooking is to use the principle of heat expansion and cold contraction. So as to separate the shell from the cashew peel and reduce the damage to the cashew nut when the shell opens.

Note: After cooking the cashews, the cashews should be placed in a ventilated place for 2-3 days.

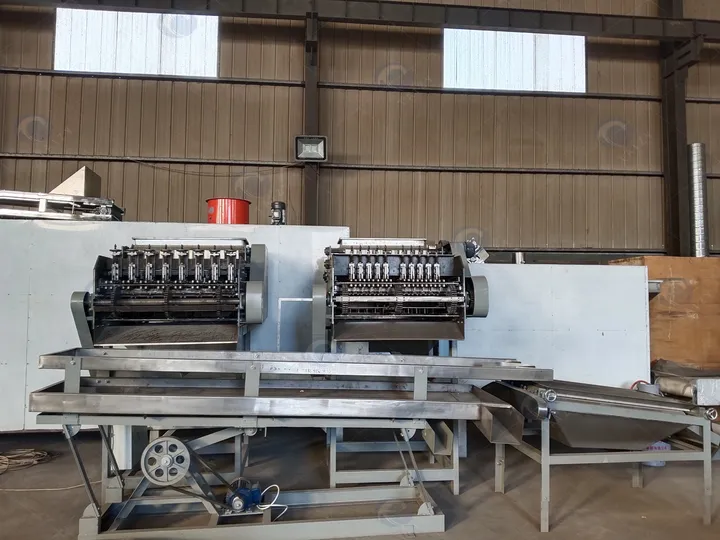

Cashew Nut Sheller And Kernel Separator

The shelling machine is divided into the semi-automatic type and automatic type. With a high rate of shellers, the characteristics of small damage to nuts, which is the automatic type of cashew sheller, are the first choice of most customers. The operation principle of these shellers is also very simple.

After the cashews are sent into the feed mouth, the roller will initially clean the cashews and remove the impurities, such as stones mixed into them. Then the cashew nuts will be evenly placed in the shell opening mould and transported to the shell opening device. After the action of the pushing device, the cashew nuts will be cut by the blade, and the cashew nuts will be opened.

After opening, the cashew shell has not been completely separated from the nuts, so it is necessary to use the shell separator to separate the shell and nuts completely.

ကာရှူးခြောက်သွေ့စက်

The cashew drying machine is used to remove excess moisture from cashews after cooking or shelling, ensuring stable quality and easier peeling.

It features uniform hot-air circulation for even drying, stable operation, and adjustable temperature and time.

This machine helps improve kernel integrity, reduce breakage, and is suitable for small, medium, and large cashew processing lines.

Cashew Kernel Peeling Machine

The cashew kernel peeling machine efficiently removes the thin skin from cashew kernels while keeping them intact. It has a high peeling rate, reduces breakage, and is suitable for small, medium, and large cashew processing lines

Cashew Kernel Grading Machine

The cashew kernel grading machine is used to sort peeled cashew kernels by size and quality. It ensures uniform grading, improves processing efficiency, and helps maintain consistent product quality. Suitable for small, medium, and large cashew processing lines.

Cashew Kernel Vacuum Packing Machine

The cashew kernel vacuum packing machine is used to vacuum-seal peeled cashew kernels, effectively extending shelf life and protecting them from moisture and oxidation. It keeps the kernels fresh and intact, operates easily, and offers fast packaging speed, suitable for small, medium, and large cashew processing plants.

Cashew Nut Production Line Features and Advantages

High Efficiency Processing

- The production line has an adjustable capacity of 100–800kg/h, suitable for small to large factories.

- The fully automatic shelling machine has a shelling rate of 90–95% with a breakage rate below 5–10%.

Full Process Coverage

Includes grading, steaming, drying, shelling, screening, secondary drying, peeling, kernel grading, roasting, and vacuum packaging, completing all processing in one line.

High-Quality Materials & Stable Structure

Parts in contact with kernels are made of 304 stainless steel, while the frame and driving components are carbon steel, ensuring durability and reliability.

High Kernel Integrity

Peeling rate and whole kernel rate exceed 90%, producing uniform, intact kernels with precise grading.

Easy Operation & Energy Efficiency

- Most machines feature button control or variable-speed motors for simple operation.

- Electric heating in the steaming oven and dryer provides high efficiency, and vacuum packaging extends kernel shelf life.

Automation & Flexibility

- The line is highly automated, reducing labor requirements and improving consistency.

- Production capacity and process settings can be adjusted to meet different factory needs.

200kg/h Cashew Kernel Processing Line – Machine List

| 设备 | Key Specifications | အရေအတွက် |

|---|---|---|

| ကာရှူးအဆင့်သတ်မှတ်ခြင်းစက် | Size: 3600×900×1600mm Voltage: 380V, 50Hz, 3-phase Power: 1.1kW Capacity: 400–500kg/h Weight: 450kg | 1 |

| Steaming Oven (24-tray, electric) | Size: 1500×600×1550mm Voltage: 380V, 50Hz, 3-phase Power: 18kW Capacity: 200kg/h Weight: 150kg Trays: 24 Material: Stainless steel | 1 |

| Cashew Shelling Machine (Fully Automatic YK-8) | Processes 8 nuts per cycle Size: 1450×1330×1550mm Weight: 480kg Capacity: 200–260kg/h Control: Button Motor: 1.5kW Voltage: 380V, 50Hz, 3-phase Shell opening rate: 90–95% Unopened rate: 3% Breakage rate: <5–10% | 1 |

| Shell & Kernel Screening Machine | Size: 2500×700×600mm Power: 0.75kW Voltage: 380V, 50Hz, 3-phase Capacity: 500kg/h Weight: 230kg Material: Carbon steel | 1 |

| Drying Machine (60-tray, electric) | Size: 2200×1800×2300mm Trolley size: 650×450×1700mm Tray size: 600×400mm Heating power: 22kW Voltage: 380V, 50Hz, 3-phase Fan power: 4×0.55kW Capacity: 400kg/batch Tray load: 1.5–2kg Weight: 900kg Material: Stainless steel trays and trolleys, carbon steel frame & motor Power: 0.2kW | 1 |

| Cashew Kernel Peeling Machine | Voltage: 380V, 50Hz, 3-phase Peeling rate: >90% Whole kernel rate: >90% Capacity: 200kg/h/set Size: 650×650×1300mm Material: 304 stainless steel Power: 7.5kW | 1 |

| လေထု ဖိအားတင်စက် | Voltage: 380V, 50Hz, 3-phase Size: 3000×900×1300mm | 1 |

| Cashew Kernel Grading Machine | Weight: 300kg Power: 0.75kW Voltage: 380V, 50Hz, 3-phase Material: Stainless steel (driving parts & frame: carbon steel) Rich Experience | 1 |

Taizy ကို ရွေးချယ်ရမည့် အကြောင်းအရင်းများ

- : Years of research, development, and manufacturing in nut processing equipment; mature and reliable technology.High Efficiency

- : Cashew production line capacity100–800kg/h , suitable for small to large factories.High Kernel Integrity

- : Peeling rate and whole kernel rate over90–98% , with low breakage.Full Process Coverage

- : From grading, cooking, drying, shelling, screening to roasting and vacuum packing—complete one-line processing.Premium Materials

- : Kernel-contact parts made of, frame and drive components 304 သံမဏိcarbon steel , durable and safe.Automated & Easy to Operate

- : Most machines havebutton control or variable-speed motors , simplifying operation and improving productivity.Energy Efficient & Eco-Friendly

- : Electric heating steaming ovens and dryers ensure high thermal efficiency; vacuum packing extends shelf life.Warranty & Certification

- : All equipment comes with quality assurance and holdsCE, ISO9001, TUV, SGS certifications for safety and reliability. Professional Support

- : Provides full-line customization, installation guidance, and after-sales service to ensure smooth production.Unshelled cashews