La línea de producción de pelado de pistachos completamente automática es un sistema de procesamiento continuo diseñado para la eliminación eficiente de cáscaras y separación de la semilla de pistachos con cáscara. Integra clasificación, pelado preciso y separación eficiente para lograr un procesamiento automatizado desde pistachos crudos hasta semillas terminadas. La línea es adecuada para el procesamiento primario de pistachos y pretratamiento antes de un procesamiento adicional.

Las cáscaras de pistacho son delgadas pero resistentes, y las semillas son frágiles, requiriendo alta precisión en el pelado y alimentación uniforme. Esta línea de producción está optimizada estructuralmente para las características del pistacho. Ofrece una alta tasa de pelado mientras mantiene baja la rotura de semillas, asegurando una calidad estable del producto.

With a capacity of 100kg per hour, the line is widely used in pistachio processing plants, nut export factories, and raw material pre-processing workshops for nut deep processing.

Materia prima aplicablels

- Pistachos con cáscara — objetivo principal de procesamiento

Consejos de procesamiento:

Para obtener los mejores resultados de pelado, los materiales deben estar secos y limpios. Evitar piedras, metales u otros objetos extraños. Ajustar la configuración según el tamaño y la dureza.

Proceso de línea de pelado de pistachos

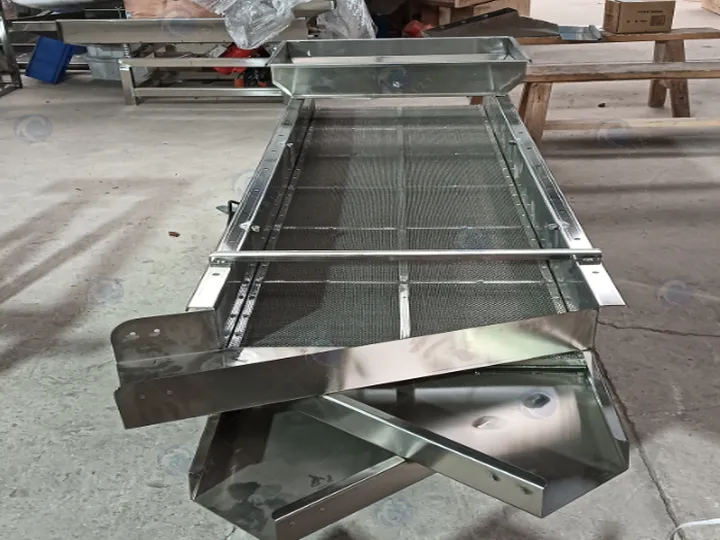

Pistachio Grading (Three-Layer Grading Screen)

Raw in-shell pistachios are first fed into the three-layer grading screen for size classification.

The machine is equipped with three screening layers, allowing pistachios to be separated into three different size grades. This ensures uniform feeding in the shelling process and effectively reduces kernel breakage caused by size variation.

- Grading levels: 3 sizes

- Machine size: 2000 × 600 × 1100 mm

- Power: 0.4 kW

Proper grading significantly improves shelling stability and helps maintain a higher whole-kernel rate.

Pistachio Shelling (Pistachio Shelling Machine)

After grading, pistachios are conveyed to the pistachio shelling machine for cracking.

The machine is fitted with a variable-speed motor, allowing the operating speed to be adjusted according to pistachio size and shell hardness, ensuring consistent shell opening performance.

- Motor power: 2.6 kW

- Voltage: 380 V / 50 Hz

- Capacity: approx. 120 kg/h

- Shell opening rate: ≥95%

- Kernel breakage rate: ≤8%

- Material: stainless steel

- Machine dimensions: 3.2 × 1 × 1.9 m

After shelling, the mixture of kernels and shells is transferred to the separation stage.

Kernel–Shell Separation (Air Separator / Dehulling Machine)

The shelled mixture is processed by a pneumatic kernel–shell separator.

By utilising the density difference between pistachio kernels and shells, the machine combines airflow and screening to achieve efficient separation.

- Potencia: 1.1 kW

- Voltage: 380 V / 50 Hz

- Overall size: 0.9 × 0.9 × 1.6 m

- Separation method: gravity + air flow

- Separation efficiency: 90–95%

Separated pistachio kernels can be sent directly for packaging or further processing, while empty shells are discharged separately.

Ventajas principales de la línea de pelado de pistachos

Designed for Pistachio Shelling Characteristics

Based on the thin yet tough shell structure of pistachios and their fragile kernels, the line combines three-layer grading with variable-speed shelling. This ensures pistachios of different sizes are cracked under matched operating conditions, reducing unnecessary kernel damage.

Stable Output for Small and Medium-Scale Processing

The production line is designed for an output of approximately 100 kg/h, featuring a compact layout and low energy consumption. It is well-suited for small pistachio processing plants, pilot production lines, and initial investment projects.

High Shell Opening Rate with Controlled Breakage

With uniform feeding and adjustable shelling speed, the line achieves a shell opening rate of ≥95%, while keeping the kernel breakage rate at ≤8%, ensuring a good balance between efficiency and product quality.

Efficient Kernel–Shell Separation

The air-based kernel–shell separator uses gravity and airflow separation, achieving a separation efficiency of 90–95%. Kernels and shells are discharged separately, significantly reducing manual sorting.

Food-Grade Materials for Safe Processing

Key components in contact with pistachios are made of stainless steel, meeting food processing hygiene standards. The structure is corrosion-resistant, easy to clean, and suitable for long-term food-grade operation.

Simple Configuration with Cost-Effective Investment

The line consists of grading, shelling, and separation units, requiring minimal installation space and maintenance. It offers a cost-effective solution for customers seeking reliable pistachio shelling at a moderate capacity.

100kg/h Fully Automatic Pistachio Shelling Proessing Line

Lista de máquinas

| No. | Nombre del equipo (inglés) | Cantidad |

|---|---|---|

| 1 | Pistachio Three-Layer Grading Screen | 1 unidad |

| 2 | Máquina de pelado de pistachos | 1 unidad |

| 3 | Air-Type Kernel–Shell Separator | 1 unidad |

Especificaciones de la máquina

| No. | Nombre de la máquina | Parámetros técnicos |

|---|---|---|

| 1 | Pistachio Three-Layer Grading Screen | Machine size: 2000 × 600 × 1100 mm Power: 0.4 kW Screen layers: 3 layers (3 size grades) |

| 2 | Máquina de pelado de pistachos | Motor: Variable-speed motor Power: 2.6 kW Voltage: 380 V / 50 Hz Capacity: approx. 120 kg/h Shell opening rate: ≥95% Kernel breakage rate: ≤8% Machine size: 3.2 × 1 × 1.9 m Packing size: 3.7 × 1.1 × 2 m Material: Acero inoxidable Weight: approx. 260 kg |

| 3 | Air-Type Kernel–Shell Separator | Potencia: 1.1 kW Voltage: 380 V / 50 Hz Overall size: 0.9 × 0.9 × 1.6 m Separation method: gravity + air flow Separation efficiency: 90–95% |

Aplicaciones globales y reconocimiento de clientes

The fully automatic pistachio shelling production line has been successfully applied in nut processing projects across Africa, Central Asia, Eastern Europe, and other regions. Customers highly praise its stability, processing efficiency, and product quality.

Si busca una solución de pelado de pistachos eficiente, confiable y escalable, contáctenos para configuraciones detalladas y soporte técnico.