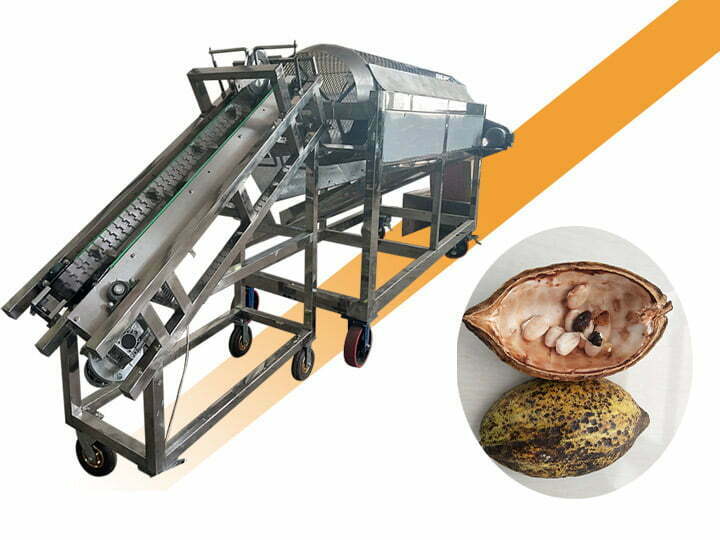

The cocoa bean is a product of cutting open pods, the seeds of the cacao tree. Growers who grow a lot of cacao trees need the help of a cocoa pod splitting machine to open the pods during the harvest season so that they can get the beans further for subsequent processing.

Operation steps of the cocoa pod splitting machine

- The operator places the cocoa pods on the conveyor belt.

- Then the pod is transported to the opening where the blade cuts the pod into two lobes.

- The broken pods are then carried along with the cocoa beans into a roller sieve.

- The roller screen sieves out the beans and pushes them out through a side outlet.

- The larger pods rotate all the way to the end and are expelled from the end of the drum.

Cocoa pod splitting machine features

- An automatic machine, melting cutting and sieving into one, after cutting the cocoa pods through the sieving machine, can be directly obtained cocoa beans.

- Compared with the traditional method of cutting cocoa pods, the damage to the cocoa beans is greatly reduced.

- Widely used in large areas of cocoa farmers.

- Compact structure, small floor space, easy to place.

- The pod cutting rate is high, and the blade can be adjusted flexibly according to the actual size of the pod.

The parameters of the cocoa pod cracking machine

| Type | Large | Small |

| Output | 800kg/h | 300-400kg/h |

| Power | 0.75kw | 0.75kw |

| Voltage | 380v, 50HZ | 380v, 50HZ |

| Size | 1.6*0.6*1.9m | 1.6*0.6*1.6m |

| Material | Stainless steel | Stainless steel |

Parameters of cocoa pod sieving machine

| Type | Large | Small |

| Output | 800kg/h | 300-400kg/h |

| Power | 1.1kw | 1.1kw |

| Voltage | 380v, 50HZ | 380v, 50HZ |

| Size | 3*1.3*2m | 2*1.3*1.7m |

| Material | Stainless steel and carbon steel | Stainless steel and carbon steel |

How to choose the right model

There are two main types of cocoa pod splitting units, large and small, and the efficiency of large machines is significantly higher than that of small machines.

If a customer grows a large acreage of cacao trees, it is recommended to opt for larger machines to avoid a backlog of pods that have not been processed in time.

If the customer’s crop is small, the selection of a small machine can meet the requirements of the cocoa pod shell processing.