花生酱研磨机 是一种可以直接将花生研磨成酱的设备。该机器为一体式研磨机,在研磨细度方面具有优势。可以研磨杏仁酱、花生酱、芝麻酱和辣椒酱。花生酱研磨机是花生酱加工过程中最重要的部分。优质的研磨机可以研磨出更好的花生酱。该机器可以在整个生产线上使用,形成高产量,也可以用于花生酱店、超市等。

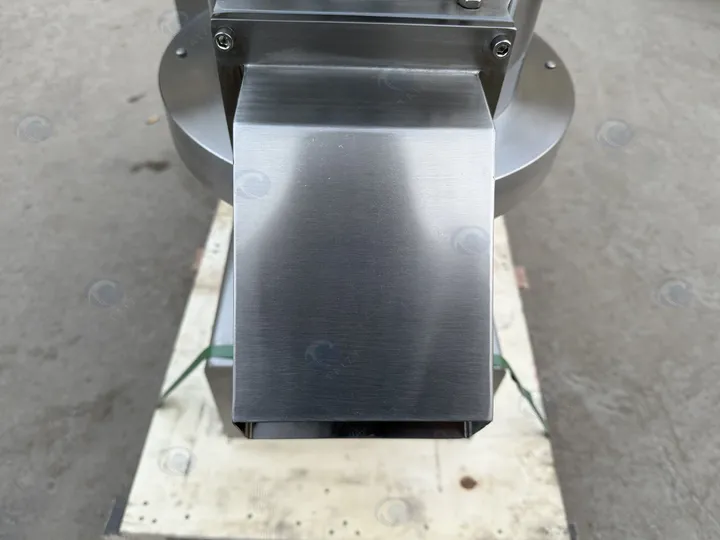

这台花生酱研磨机的容量为 0.005 到 18 吨。整机采用304不锈钢制造,易于清洁,防腐蚀,耐用。配备铜芯电机,比普通电机寿命更长,是一款性价比高的机器。”

花生酱研磨机可以加工哪些产品?

花生酱研磨机可以研磨花生酱、芝麻酱、辣椒酱、果酱等产品。花生酱研磨机动力更强,可用于生产多种产品。在生产花生酱的过程中,可以将整粒花生放入机器中研磨。当然,我们应注意花生的预处理;即,花生的红皮会有苦味,如果不去除,会影响花生酱的口感。在商业花生酱生产过程中,大多数 花生去壳机被使用。去壳后,直接放入研磨机研磨。”

花生酱研磨机参数

| 模型 | TZ-50 | TZ-80 | TZ-110 | TZ-130 | TZ-180 | TZ-240 | TZ-300 |

|---|---|---|---|---|---|---|---|

| 成品尺寸 (mm) | 2–50 | 2–50 | 2–50 | 2–50 | 2–50 | 2–50 | 2–50 |

| 容量 (t/h) | 0.005–0.03 | 0.1–0.5 | 0.3–1 | 0.4–2.0 | 0.8–6.0 | 1.0–8.0 | 6–18 |

| 电机功率(千瓦) | 1.5 | 4 | 7.5 | 11 | 18.5 / 22 | 37 / 45 | 55 / 75 |

| 电压 (V) | 220 / 380 | 220 / 380 | 380 | 380 | 380 | 380 | 380 |

| 转速 (r/min) | 2820 | 2890 | 2930 | 2930 | 2930 | 2970 | 2970 |

| 转子直径 (mm) | 50 | 80 | 110 | 130 | 180 | 240 | 300 |

| 长度 (mm) | 520 | 685 | 790 | 975 | 981 | 1319 | 1400 |

| 宽度 (mm) | 250 | 335 | 390 | 456 | 476 | 500 | 600 |

| 高度 (mm) | 555 | 928 | 920 | 1054 | 1124 | 1276 | 1400 |

| 重量(公斤) | 70 | 210 | 280 | 400 | 420 | 1000 | 1600 |

我们有不同型号的花生酱研磨机,不同型号的机器产量不同,TZ-50 是最小的型号,处理能力约为每小时0.8吨,每台机器都配备有水冷系统。

花生酱机是如何工作的?

通过不同几何形状的定子和转子的相对运动,在高速旋转下,经过其环形可变间隙的处理材料受到强剪切力、摩擦力和冲击力的作用,在自重、气压和离心力的作用下,材料被有效分散、破碎、乳化和混合,以获得理想的产品。

花生酱机特点

- 坚果研磨机可以在短时间内粉碎坚果,并具有混合、搅拌、分散和乳化的功能。

- 机器采用不锈钢制成,坚固耐用,不易损坏

- 操作简单,易于清洁,机器占地面积小,易于维护。

- 功能多样,花生酱研磨机可加工多种物料,具有多种功能

如何才能生产出高品质的花生酱?

制作花生酱时,最重要的要求之一是花生酱足够细腻。花生酱颗粒必须在微米范围内,以确保花生酱的质量,不易“结块”,因此花生只能充分研磨。优质的花生酱。

商业花生酱生产工艺

花生酱生产线 包括从去壳、烘烤、冷却、去皮、研磨到包装的几个重要步骤。但如果购买的原料是花生仁,则无需去壳,直接烘烤花生仁即可。