腰果生产线主要设计用于将未剥壳腰果加工成剥壳腰果仁,并完成真空包装。整线包括分级、烹饪、干燥、剥壳、筛选、二次干燥、去壳、仁分级、烘烤和真空包装。剥壳率超过 98%,非常适合各种规模的腰果加工厂。

该腰果仁生产线产能为100–800kg/h。根据您的生产需求,可选择全自动或半自动腰果加工线。欢迎联系我们获取更多详情和专业咨询。

腰果生产线工艺流程

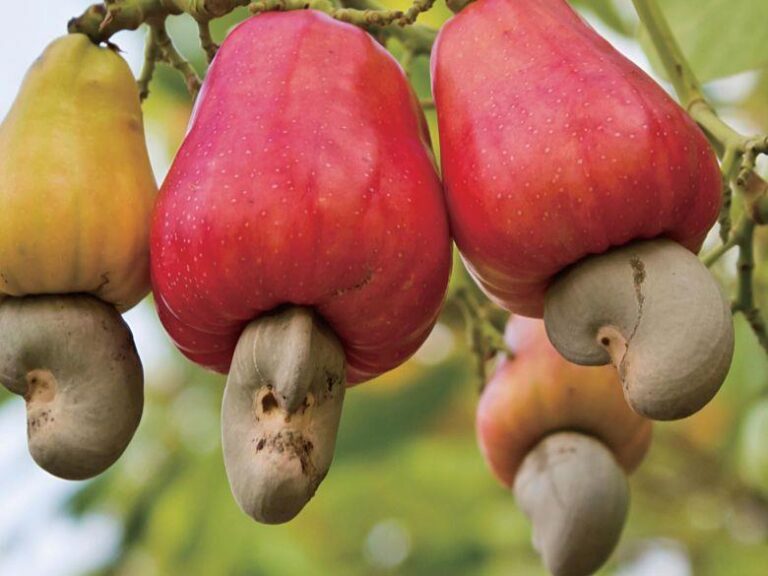

This cashew production line is a complete technological process, which is the preliminary comprehensive processing of cashew after picking. The whole production line adopts semi-automatic operation, compared with the traditional manual processing, the efficiency will be higher, at the same time cashew damage rate will be greatly reduced.

腰果生产线的加工工艺需要以下机器:

腰果分级机

First of all, the initial grading of cashews is to facilitate the subsequent opening of the shell. Because the size of cashews varies, the shelling machine uses the distance between the blades to open the shell. So before opening the shell need to ensure that the size of the cashews is uniform.

The size of cashew nuts is generally divided into 16, 18, 20, 22, and 24mm. The grading machine realises the grading processing of cashew nuts through screens with different pore diameters. Customers can choose the number of grades that should be divided according to actual requirements.

腰果烹饪机

分级后的腰果放入烹饪箱。根据腰果的大小,烹饪时间不同。体积较小的腰果烹饪时间较长,体积较大的则相反。

The main purpose of cooking is to use the principle of heat expansion and cold contraction. So as to separate the shell from the cashew peel and reduce the damage to the cashew nut when the shell opens.

注意:烹饪完腰果后,应放置通风处2-3天。

腰果壳碎机和仁分离机

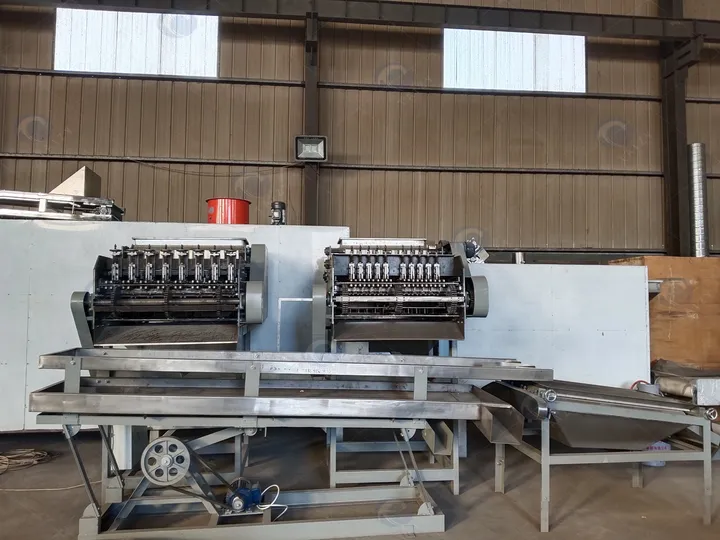

The shelling machine is divided into the semi-automatic type and automatic type. With a high rate of shellers, the characteristics of small damage to nuts, which is the automatic type of cashew sheller, are the first choice of most customers. The operation principle of these shellers is also very simple.

After the cashews are sent into the feed mouth, the roller will initially clean the cashews and remove the impurities, such as stones mixed into them. Then the cashew nuts will be evenly placed in the shell opening mould and transported to the shell opening device. After the action of the pushing device, the cashew nuts will be cut by the blade, and the cashew nuts will be opened.

After opening, the cashew shell has not been completely separated from the nuts, so it is necessary to use the shell separator to separate the shell and nuts completely.

腰果烘干机

The cashew drying machine is used to remove excess moisture from cashews after cooking or shelling, ensuring stable quality and easier peeling.

It features uniform hot-air circulation for even drying, stable operation, and adjustable temperature and time.

This machine helps improve kernel integrity, reduce breakage, and is suitable for small, medium, and large cashew processing lines.

腰果仁去壳机

腰果仁去壳机高效去除腰果仁的薄皮,同时保持完整。剥壳率高,减少破碎,适用于小、中、大型腰果加工线。

腰果仁分级机

腰果仁分级机用于按大小和质量对剥壳腰果仁进行分类。确保分级均匀,提高加工效率,帮助保持产品质量稳定。适用于小、中、大型腰果加工线。

腰果仁真空包装机

腰果仁真空包装机用于对剥壳后的腰果仁进行真空封装,有效延长保质期,防潮抗氧化。保持腰果新鲜完整,操作简便,包装速度快,适用于小、中、大型腰果加工厂。

腰果生产线的特点与优势

高效加工

- 生产线容量可调节为100–800kg/h,适合小型到大型工厂。

- 全自动剥壳机剥壳率达90–95%,破碎率低于5–10%。

全流程覆盖

包括分级、蒸煮、干燥、剥壳、筛选、二次干燥、去壳、仁分级、烘烤和真空包装,一线完成所有工序。

优质材料与稳定结构

与仁接触的部分采用304不锈钢,框架和驱动部件为碳钢,确保耐用可靠。

高仁完整性

剥壳率和完整仁率均超过90%,生产出均匀、完整、分级准确的腰果仁。

操作简便 & 节能

- 大多数设备配有按钮控制或变速电机,操作简便。

- 蒸汽炉和干燥机的电加热提供高效率,真空包装延长仁的保质期。

自动化 & 灵活性

- 该生产线自动化程度高,减少人工需求,提高一致性。

- 产能和工艺参数可调节,以满足不同工厂的需求。

200kg/h腰果仁加工线——设备清单

| 设备 | 关键参数 | 数量 |

|---|---|---|

| 腰果分级机 | 尺寸:3600×900×1600mm 电压:380V,50Hz,三相 功率:1.1kW 产能:400–500kg/h 重量:450kg | 1 |

| 蒸汽炉(24托盘,电动) | 尺寸:1500×600×1550mm 电压:380V,50Hz,三相 功率:18kW 产能:200kg/h 重量:150kg 托盘: 24 材质: 不锈钢 | 1 |

| 腰果壳机(全自动YK-8) | 每个循环处理8个仁 尺寸:1450×1330×1550mm 重量:480kg 产能:200–260kg/h 控制:按钮 电机:1.5kW 电压:380V,50Hz,三相 开壳率:90–95% 未开封率:3% 破碎率:<5–10% | 1 |

| 壳和仁筛选机 | 尺寸:2500×700×600mm 功率:0.75kW 电压:380V,50Hz,三相 产能:500kg/h 重量:230kg 材料:碳钢 | 1 |

| 干燥机(60托盘,电动) | 尺寸:2200×1800×2300mm 手推车尺寸:650×450×1700mm 托盘尺寸:600×400mm 加热功率:22kW 电压:380V,50Hz,三相 风机功率:4×0.55kW 产能:400kg/批 托盘载重:1.5–2kg 重量:900kg 材料:不锈钢托盘和手推车,碳钢框架和电机 功率:0.2kW | 1 |

| 腰果仁去壳机 | 电压:380V,50Hz,三相 剥壳率:>90% 完整仁率:>90% 产能:200kg/h/套 尺寸:650×650×1300mm 材料:304不锈钢 功率:7.5kW | 1 |

| 空气压缩机 | 电压:380V,50Hz,三相 尺寸:3000×900×1300mm | 1 |

| 腰果仁分级机 | 重量:300kg 功率:0.75kW 电压:380V,50Hz,三相 材料:不锈钢(驱动部分和框架为碳钢) 丰富经验 | 1 |

为什么选择Taizy?

- :多年的坚果加工设备研发制造经验,技术成熟可靠。高效率

- 腰果生产线产能100–800kg/h ,适用于小型到大型工厂。高仁完整性

- : 剥壳率和完整仁率超过90–98% , 破碎率低。全流程覆盖

- : 从分级、烹饪、干燥、剥壳、筛选到烘烤和真空包装——一条线完成全部工序。优质材料

- : 仁接触部分采用,框架和驱动部件 304不锈钢碳钢 ,耐用且安全。自动化,操作简便

- :大多数设备都具有按钮控制或变速电机 ,简化操作,提高生产效率。节能环保

- : 电加热蒸汽炉和干燥机确保高热效率;真空包装延长保质期。质保与认证

- : 所有设备均提供质量保证并持有CE,ISO9001,TUV,SGS 安全可靠的认证证书。 专业支持

- : 提供全线定制、安装指导和售后服务,确保生产顺利进行。未剥壳腰果