Cocoa powder is a kind of powder made from cocoa beans. It is not only very common in the field of various food processing, but also a common way of eating cocoa powder as a grew. However, there are many package types of cocoa powder in the market. And the following article will introduce the most common types of packaging for cocoa powder.

Introduction to the types of cocoa powder

The fat and sugar content of cocoa powder is very low. And it also contains a variety of trace elements and vitamins needed by the human body. The most important thing is that it contains two powerful antioxidants, polyphenols and flavonoids, which can boost our immune system. It also has the effect of lowering blood pressure, enhancing blood circulation, preventing cancer and cardiovascular diseases.

Generally speaking, the classification of cocoa powder will be based on the content of cocoa butter. Divided into high-fat cocoa powder, medium-fat cocoa powder, and low-fat cocoa powder.

There is also a more common classification, namely: according to the alkalization process, it divided into natural cocoa powder and alkalized cocoa powder.

How should cocoa powder be packaged?

When we walked into the cocoa powder sales area in the supermarket. We can find that the packaging of cocoa powder is diverse, including packaging materials, shapes, specifications, and sizes.

The first type of packaging is to use environmentally friendly paper materials. This packaging material is not only non-polluting to the environment but also has a moisture-proof effect. It often used to package various powdery or granular items;

Another common packaging is canned cocoa powder. Which is more convenient to store and carry;

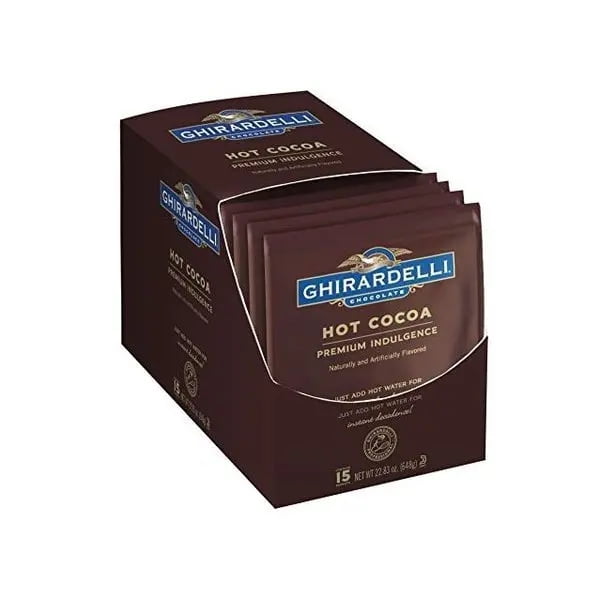

Another kind of cocoa powder often packages in a portable pouch, which is similar to the small pouches of coffee we have seen. It is very convenient for daily consumption and carrying.

Types of cocoa powder packaging machine

Regarding the above different types of cocoa powder packaging forms, there are also many types of cocoa powder packaging machines. The most commonly used are powder packaging machines and semi-automatic powder/granule packaging machines.

According to the actual market situation, the powder packaging machine is more used, because the finished product after packaging is not only easy to carry but also has no trouble with improper storage.

Finished product display after packaging by the powder packaging machine