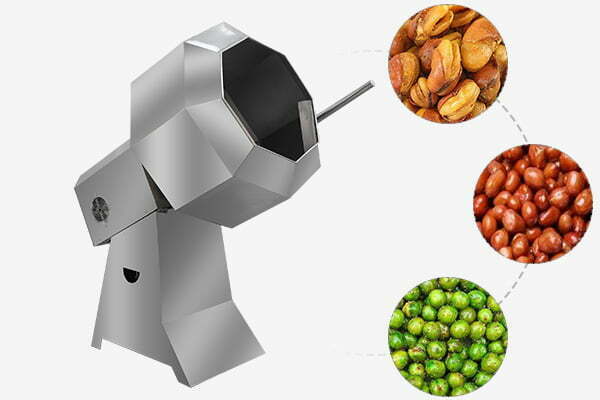

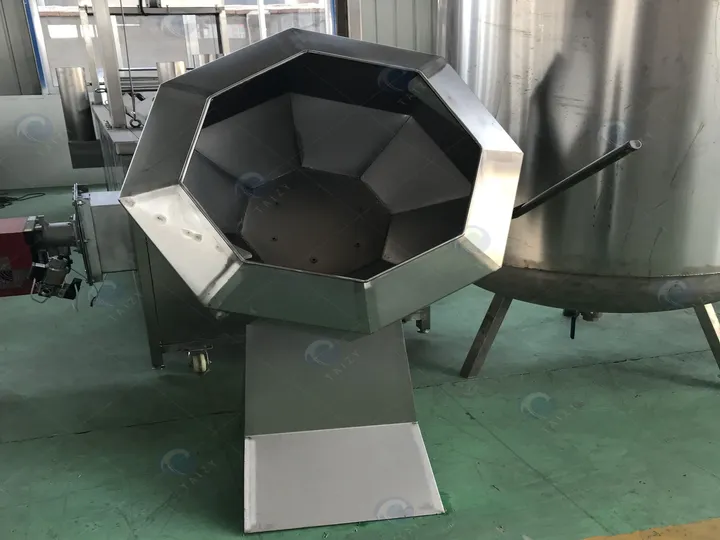

Seasoning machine for Coating Peanut, also known as a rotary drum mixer, is a high-efficiency automated machine designed for coating peanuts and snack foods. Its unique octagonal drum ensures even seasoning for fried, puffed, nut-based, and other snack products.

Depending on the model, it can produce 200–700 kg per hour, significantly reducing labor costs while ensuring even mixing and preventing breakage of delicate materials.

This popular seasoning machine for coating peanuts is made entirely of stainless steel. It features automatic discharge, variable-speed control, and even seasoning. Easy to operate and clean, it produces coated peanuts with consistent flavor and no breakage.

Key Features of Seasoning Machine For Coating Peanut

Even Seasoning

The octagonal drum allows coated peanuts to tumble and lift fully inside the barrel, preventing clumping and dead zones for uniform seasoning and consistent taste.

Multi-Seasoning Applications

Suitable for mixing and seasoning processes, compatible with powder, paste, and liquid seasonings.

Low Breakage Design

Gentle and stable tumbling makes it ideal for fragile products such as chips, puffed snacks, and nuts, effectively reducing breakage.

Adjustable Parameters, High Flexibility

Drum speed and tilt angle are adjustable to precisely control seasoning time for different ingredients.

Automated Operation

Supports automatic seasoning feeding and automatic discharge, reducing manual labor and improving efficiency.

Food-Grade Safe Structure

Made entirely of food-grade stainless steel, corrosion-resistant, easy to clean, and compliant with food hygiene standards.

Wide Application Range

Suitable for snack foods, braised foods, ready-to-eat meals, meat products, and other food processing applications.

High Processing Capacity

Designed for continuous operation with stable performance, meeting medium to large-scale production needs while maintaining consistent seasoning quality.

The Application Field of the Seasoning Machine

- Fried foods

- Puff snacks

- Nuts and seeds

- Chips, crackers, pellets

- Other leisure and snack foods

Parameters of Peanut Coating Seasoning Machine

| Öğe | TZ-700 | TZ-800 | TZ-1000 | TZ-1200 |

| Kapasite | 200kg/saat | 300kg/s | 400kg/saat | 700kg/h |

| Ağırlık | 50kg | 85kg | 110kg | 150kg |

| Boyut | 1000*700*1400mm | 1200*800*1500mm | 1500*920*1700mm | 2000*1100*2200mm |

| Güç | 0.75kw | 1.1kw | 2.2kw | 2.2kw |

| Gerilim | 380v | 380v | 380v | 380v |

Advantages of Peanut Coating Seasoning Machine

Wide Production Range for Different Scales

Available in 200 / 300 / 400 / 700 kg/h models, suitable for small factories to medium and large-scale food production lines, supporting continuous and stable operation.

Octagonal Drum for Even Coating

The octagonal drum design allows peanuts to tumble and lift continuously, preventing clumping and sticking. Powder and paste coatings are applied evenly, ensuring consistent color and taste.

Low Breakage Rate, Protects Coating Integrity

Gentle and controllable tumbling is ideal for fragile products like coated peanuts, reducing breakage and coating loss.

Food-Grade Stainless Steel Construction

Made entirely of corrosion-resistant, easy-to-clean stainless steel, meeting hygiene standards for long-term, high-frequency use.

Optimized Power & Stable Operation

Equipped with 0.75–2.2 kW motors matched to production capacity, providing smooth, energy-efficient operation suitable for long continuous runs.

Automatic Discharge for Higher Efficiency

The drum can tilt automatically for discharge, reducing manual labor and shortening batch operation time for improved overall productivity.

Compact Design, Small Footprint

Weighing 50–150 kg, the machine’s compact structure allows a flexible workshop layout and easy installation and maintenance.

Industrial Voltage for Factory Use

Standard 380 V industrial voltage ensures stable operation; other voltage configurations can be customized to meet client requirements.

Precautions And Maintenance During Use

- Fıstık kaplama için bir baharatlama makinesi seçerken, gerçek üretim hacmini karşılayan makine modelini seçin, böylece en düşük maliyetle en yüksek kârı elde edersiniz.

- Baharatlama makinesi kullanılırken yatay bir zemine yerleştirilmelidir, böylece makinenin çalışma sırasında kaymasını önler.

- Ekipmanın çalışması sırasında elinizi ekipmanın içine sokmamaya dikkat edin. Malzemelerin taşınmasını kontrol etmeniz gerekiyorsa, işlemi gerçekleştirmek için özel aletler kullanabilirsiniz.

- Ayrıca, yiyecek ile temas eden parçaların düzenli olarak temizlenmesi gerekmektedir. Öncelikle, etkili bir temizlik etkisine sahip nemli bir bezle silin. Son olarak, kalıntılarla yiyecekleri kirletmemek için bunları kuru bir bezle kurutmayı unutmamak önemlidir.

- Her çeyrek, baharat makinesinin transmisyon parçalarına yağ eklemek gereklidir, böylece makinenin normal üretim ve çalışması sağlanır.