The production of peanut butter is in great demand on the market, but the peanut butter n lines output is very different, and the requirements for the output of the labor and the equipment required are also different, so the company provides customers with two different peanut butter production lines, Automatic peanut butter production line and Semi-automatic peanut butter production line.The output that these two production lines can produce is also diverse. This can meet the needs of different customers, and it can also allow more people to have their own suitable machines. While making full use of their own resources, they will not This results in idle machines and insufficient machines.

Comparison of the two peanut butter production line

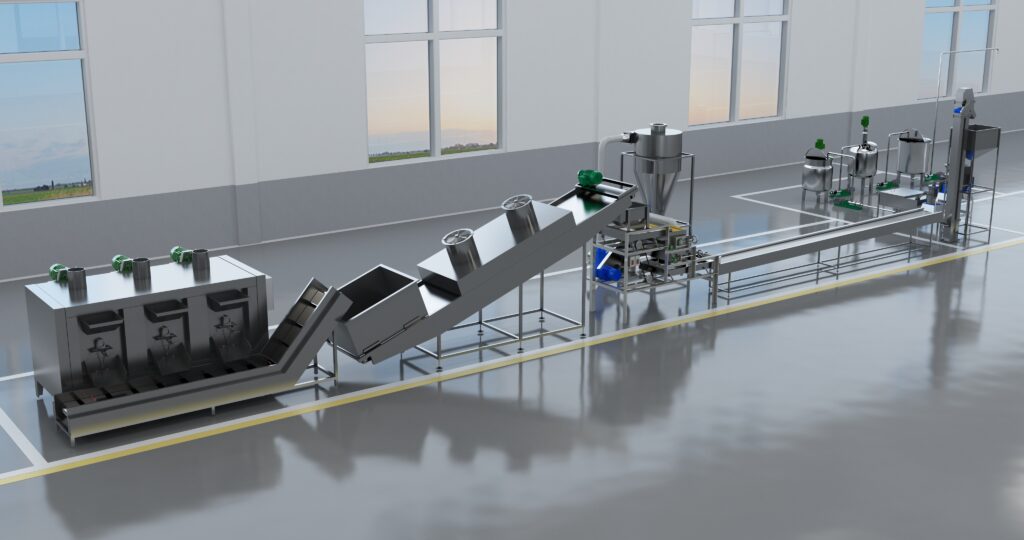

Below are the 3D pictures of the automatic peanut butter production line and the semi-automatic and peanut butter production line

semi-automatic peanut butter lines

semi-automatic peanut butter lines

The baking machine is not the same

The biggest difference between semi-automatic and fully automatic production lines is the difference in the baking machine. The semi-automatic production line is that the workflow is first baking and then cooling. After cooling, the peanuts are peeled, and then the production processes such as grinding and seasoning are carried out. The fully automatic peanut butter production line integrates baking and cooling. In other words, the fully automatic peanut butter production line is cooled while roasting.

Automatic continuous oven

Semi-automatic intermittent oven

Different baking time

The baking time of a semi-automatic production line is about 45-50 minutes, while the baking time of a fully automatic production line is about 30 minutes. From this point of view, the fully automatic peanut butter production line saves more time. In addition, the fully automatic peanut butter production line saves labor, but customers can purchase according to their own production needs when purchasing. The semi-automatic peanut butter production line is more suitable for machines with a smaller output.

How to choose a peanut butter lines

The first thing that should be considered is the issue of output. For large-volume production processes such as 500kg/h-1000kg/h, continuous production lines can work better. Cost issues and capital issues are issues that we must consider when selecting machines. In addition , And the area of the plant, which is determined according to the area of the plant and the size of the machine. Therefore, there are many factors to consider when purchasing a machine.Our company has a very professional peanut butter lines team and strong technical support Our company will decide according to the specific situation of each customer. Analysis.